Cutters with Bore

Cutter with Bore - LEUCO

Cutter with Bore - LEUCO

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

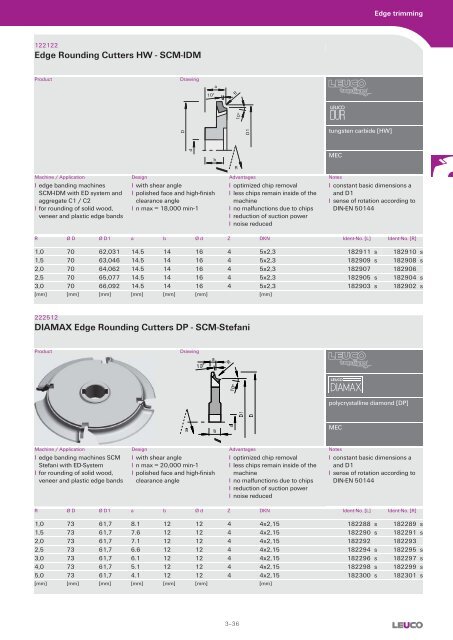

Edge trimming<br />

122122<br />

Edge Rounding <strong>Cutters</strong> HW - SCM-IDM<br />

Product<br />

Drawing<br />

10°<br />

a<br />

R<br />

10°<br />

D<br />

D1<br />

tungsten carbide [HW]<br />

d<br />

b<br />

Machine / Application Design Advantages Notes<br />

Ι edge banding machines<br />

SCM-IDM <strong>with</strong> ED system and<br />

aggregate C1 / C2<br />

Ι for rounding of solid wood,<br />

veneer and plastic edge bands<br />

Ι <strong>with</strong> shear angle<br />

Ι polished face and high-finish<br />

clearance angle<br />

Ι n max = 18,000 min-1<br />

Ι optimized chip removal<br />

Ι less chips remain inside of the<br />

machine<br />

Ι no malfunctions due to chips<br />

Ι reduction of suction power<br />

Ι noise reduced<br />

Ι constant basic dimensions a<br />

and D1<br />

Ι sense of rotation according to<br />

DIN-EN 50144<br />

R<br />

MEC<br />

R Ø D Ø D1 a b Ø d Z DKN Ident-No. [L] Ident-No. [R]<br />

1,0 70 62,031 14.5 14 16 4 5x2,3 182911 s 182910 s<br />

1,5 70 63,046 14.5 14 16 4 5x2,3 182909 s 182908 s<br />

2,0 70 64,062 14.5 14 16 4 5x2,3 182907 182906<br />

2,5 70 65,077 14.5 14 16 4 5x2,3 182905 s 182904 s<br />

3,0 70 66,092 14.5 14 16 4 5x2,3 182903 s 182902 s<br />

[mm] [mm] [mm] [mm] [mm] [mm] [mm]<br />

222512<br />

DIAMAX Edge Rounding <strong>Cutters</strong> DP - SCM-Stefani<br />

Product<br />

Drawing<br />

polycrystalline diamond [DP]<br />

MEC<br />

Machine / Application Design Advantages Notes<br />

Ι edge banding machines SCM<br />

Stefani <strong>with</strong> ED-System<br />

Ι for rounding of solid wood,<br />

veneer and plastic edge bands<br />

Ι <strong>with</strong> shear angle<br />

Ι n max = 20,000 min-1<br />

Ι polished face and high-finish<br />

clearance angle<br />

Ι optimized chip removal<br />

Ι less chips remain inside of the<br />

machine<br />

Ι no malfunctions due to chips<br />

Ι reduction of suction power<br />

Ι noise reduced<br />

Ι constant basic dimensions a<br />

and D1<br />

Ι sense of rotation according to<br />

DIN-EN 50144<br />

R Ø D Ø D1 a b Ø d Z DKN Ident-No. [L] Ident-No. [R]<br />

1,0 73 61,7 8.1 12 12 4 4x2,15 182288 s 182289 s<br />

1,5 73 61,7 7.6 12 12 4 4x2,15 182290 s 182291 s<br />

2,0 73 61,7 7.1 12 12 4 4x2,15 182292 182293<br />

2,5 73 61,7 6.6 12 12 4 4x2,15 182294 s 182295 s<br />

3,0 73 61,7 6.1 12 12 4 4x2,15 182296 s 182297 s<br />

4,0 73 61,7 5.1 12 12 4 4x2,15 182298 s 182299 s<br />

5,0 73 61,7 4.1 12 12 4 4x2,15 182300 s 182301 s<br />

[mm] [mm] [mm] [mm] [mm] [mm] [mm]<br />

3–36