The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

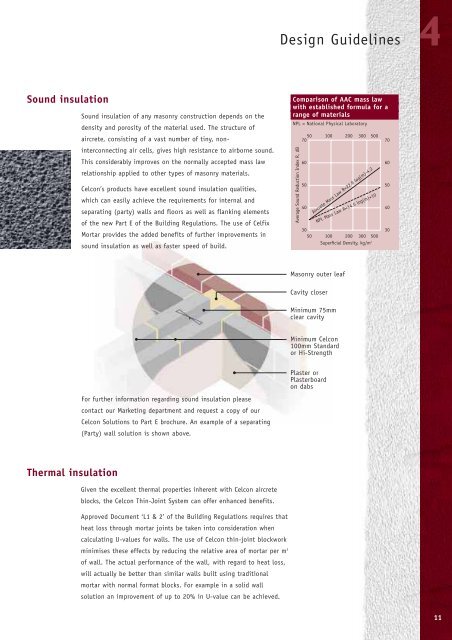

Sound insulation<br />

<strong>The</strong>rmal insulation<br />

Sound insulation of any masonry construction depends on the<br />

density and porosity of the material used. <strong>The</strong> structure of<br />

aircrete, consisting of a vast number of tiny, noninterconnecting<br />

air cells, gives high resistance to airborne sound.<br />

This considerably improves on the normally accepted mass law<br />

relationship applied to other types of masonry materials.<br />

<strong>Celcon</strong>’s products have excellent sound insulation qualities,<br />

which can easily achieve the requirements for internal and<br />

separating (party) walls and floors as well as flanking elements<br />

of the new Part E of the Building Regulations. <strong>The</strong> use of Celfix<br />

Mortar provides the added benefits of further improvements in<br />

sound insulation as well as faster speed of build.<br />

For further information regarding sound insulation please<br />

contact our Marketing department and request a copy of our<br />

<strong>Celcon</strong> Solutions to Part E brochure. An example of a separating<br />

(Party) wall solution is shown above.<br />

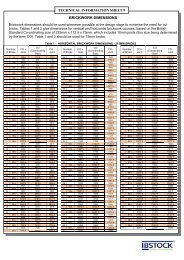

Given the excellent thermal properties inherent with <strong>Celcon</strong> aircrete<br />

blocks, the <strong>Celcon</strong> <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> can offer enhanced benefits.<br />

Approved Document ‘L1 & 2’ of the Building Regulations requires that<br />

heat loss through mortar joints be taken into consideration when<br />

calculating U-values for walls. <strong>The</strong> use of <strong>Celcon</strong> thin-joint blockwork<br />

minimises these effects by reducing the relative area of mortar per m2 of wall. <strong>The</strong> actual performance of the wall, with regard to heat loss,<br />

will actually be better than similar walls built using traditional<br />

mortar with normal format blocks. For example in a solid wall<br />

solution an improvement of up to 20% in U-value can be achieved.<br />

Design <strong>Guide</strong>lines<br />

Comparison of AAC mass law<br />

with established formula for a<br />

range of materials<br />

NPL = National Physical Laboratory<br />

Average Sound Reduction Index R, dB<br />

50 100 200 300 500<br />

70<br />

60<br />

50<br />

40<br />

30<br />

50 100 200 300 500<br />

Superficial Density, kg/m 2<br />

<strong>Masonry</strong> outer leaf<br />

Cavity closer<br />

Minimum 75mm<br />

clear cavity<br />

Minimum <strong>Celcon</strong><br />

100mm Standard<br />

or Hi-Strength<br />

Plaster or<br />

Plasterboard<br />

on dabs<br />

Aircrete Mass Law R=22.9 log(m)-4.2<br />

NPL Mass Law R=14.5 log(m)+10<br />

70<br />

60<br />

50<br />

40<br />

30<br />

4<br />

11