The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

The Celcon Thin-Joint System A Definitive Guide - Masonry First

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4 Design <strong>Guide</strong>lines<br />

16<br />

Lintels<br />

Wall ties<br />

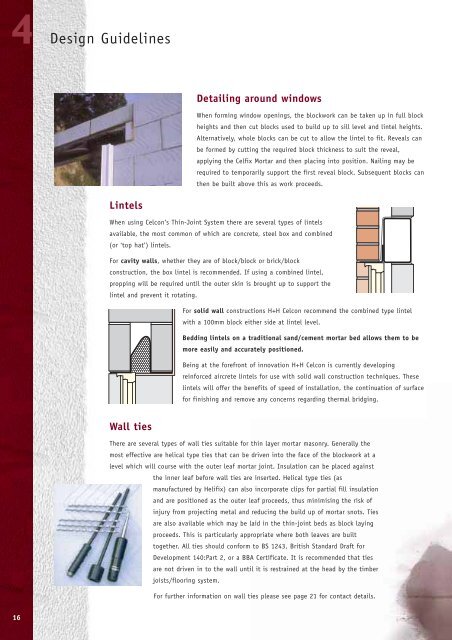

Detailing around windows<br />

When forming window openings, the blockwork can be taken up in full block<br />

heights and then cut blocks used to build up to sill level and lintel heights.<br />

Alternatively, whole blocks can be cut to allow the lintel to fit. Reveals can<br />

be formed by cutting the required block thickness to suit the reveal,<br />

applying the Celfix Mortar and then placing into position. Nailing may be<br />

required to temporarily support the first reveal block. Subsequent blocks can<br />

then be built above this as work proceeds.<br />

When using <strong>Celcon</strong>’s <strong>Thin</strong>-<strong>Joint</strong> <strong>System</strong> there are several types of lintels<br />

available, the most common of which are concrete, steel box and combined<br />

(or ‘top hat’) lintels.<br />

For cavity walls, whether they are of block/block or brick/block<br />

construction, the box lintel is recommended. If using a combined lintel,<br />

propping will be required until the outer skin is brought up to support the<br />

lintel and prevent it rotating.<br />

For solid wall constructions H+H <strong>Celcon</strong> recommend the combined type lintel<br />

with a 100mm block either side at lintel level.<br />

Bedding lintels on a traditional sand/cement mortar bed allows them to be<br />

more easily and accurately positioned.<br />

Being at the forefront of innovation H+H <strong>Celcon</strong> is currently developing<br />

reinforced aircrete lintels for use with solid wall construction techniques. <strong>The</strong>se<br />

lintels will offer the benefits of speed of installation, the continuation of surface<br />

for finishing and remove any concerns regarding thermal bridging.<br />

<strong>The</strong>re are several types of wall ties suitable for thin layer mortar masonry. Generally the<br />

most effective are helical type ties that can be driven into the face of the blockwork at a<br />

level which will course with the outer leaf mortar joint. Insulation can be placed against<br />

the inner leaf before wall ties are inserted. Helical type ties (as<br />

manufactured by Helifix) can also incorporate clips for partial fill insulation<br />

and are positioned as the outer leaf proceeds, thus minimising the risk of<br />

injury from projecting metal and reducing the build up of mortar snots. Ties<br />

are also available which may be laid in the thin-joint beds as block laying<br />

proceeds. This is particularly appropriate where both leaves are built<br />

together. All ties should conform to BS 1243, British Standard Draft for<br />

Development 140:Part 2, or a BBA Certificate. It is recommended that ties<br />

are not driven in to the wall until it is restrained at the head by the timber<br />

joists/flooring system.<br />

For further information on wall ties please see page 21 for contact details.