Extruders - A Special Supplement from Rubber & Tyre Machinery World

Rubber extruders have a varied field of application. So, when you come across a rubber profile, strip, hose, cable, wire, cord coating, tire tread, v-belt, tube, or blank remember that they are only a few handful of products manufactured using extrusion process. In this Knowledge On-The-Go Special Supplement, we bring to you a ‘collector’s edition’ on Extruders and Extrusion incorporating the fundamentals.

Rubber extruders have a varied field of application. So, when you come across a rubber profile, strip, hose, cable, wire, cord coating, tire tread, v-belt, tube, or blank remember that they are only a few handful of products manufactured using extrusion process. In this Knowledge On-The-Go Special Supplement, we bring to you a ‘collector’s edition’ on Extruders and Extrusion incorporating the fundamentals.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

| EXTRUDERS |<br />

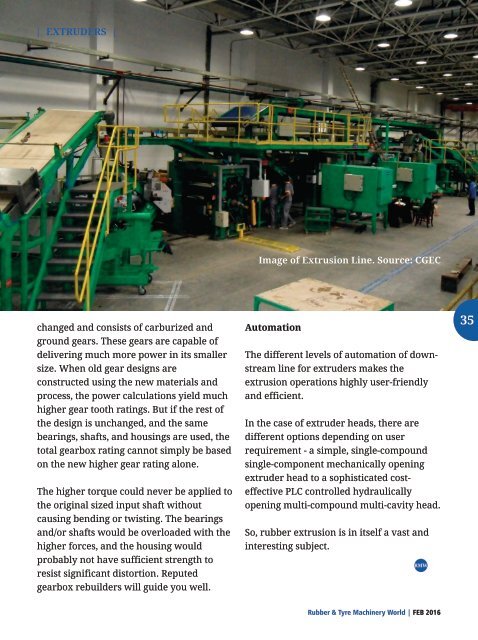

Image of Extrusion Line. Source: CGEC<br />

changed and consists of carburized and<br />

ground gears. These gears are capable of<br />

delivering much more power in its smaller<br />

size. When old gear designs are<br />

constructed using the new materials and<br />

process, the power calculations yield much<br />

higher gear tooth ratings. But if the rest of<br />

the design is unchanged, and the same<br />

bearings, shafts, and housings are used, the<br />

total gearbox rating cannot simply be based<br />

on the new higher gear rating alone.<br />

The higher torque could never be applied to<br />

the original sized input shaft without<br />

causing bending or twisting. The bearings<br />

and/or shafts would be overloaded with the<br />

higher forces, and the housing would<br />

probably not have sufficient strength to<br />

resist significant distortion. Reputed<br />

gearbox rebuilders will guide you well.<br />

Automation<br />

The different levels of automation of downstream<br />

line for extruders makes the<br />

extrusion operations highly user-friendly<br />

and efficient.<br />

In the case of extruder heads, there are<br />

different options depending on user<br />

requirement - a simple, single-compound<br />

single-component mechanically opening<br />

extruder head to a sophisticated costeffective<br />

PLC controlled hydraulically<br />

opening multi-compound multi-cavity head.<br />

So, rubber extrusion is in itself a vast and<br />

interesting subject.<br />

RMW<br />

35<br />

<strong>Rubber</strong> & <strong>Tyre</strong> <strong>Machinery</strong> <strong>World</strong> | FEB 2016