Corporate Responsibility & Sustainability Report 2015/2016

1XlqBpD

1XlqBpD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CORPORATE RESPONSIBILITY & SUSTAINABILITY REPORT <strong>2015</strong> — <strong>2016</strong><br />

Water Stewardship<br />

OUR TARGETS<br />

100%<br />

Protect the future sustainability of our water<br />

sources and safely return to nature 100 percent<br />

of the wastewater from our manufacturing<br />

operations by 2020.<br />

1.2 liters per liter<br />

Reduce the amount of water we consume so<br />

that by 2020 we use an average of 1.2 liters<br />

of water to manufacture every liter of product.<br />

OUR COMMITMENT<br />

We will minimize the amount of water we use in our value chain, establish<br />

a water sustainable operation and set the standard for water efficiency.<br />

INTRODUCTION<br />

Water is a precious resource, critical to our communities, our ecosystems and<br />

the sustainability of our business. It’s the main component of our beverages<br />

and essential to our manufacturing processes and agricultural ingredients.<br />

It’s vital we use it as efficiently as possible.<br />

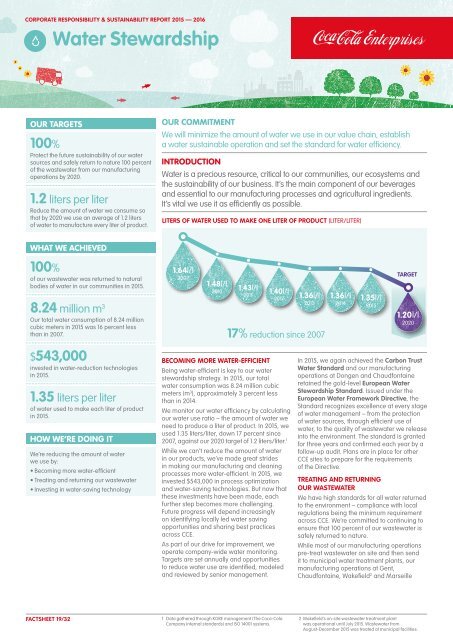

LITERS OF WATER USED TO MAKE ONE LITER OF PRODUCT (LITER/LITER)<br />

WHAT WE ACHIEVED<br />

100%<br />

of our wastewater was returned to natural<br />

bodies of water in our communities in <strong>2015</strong>.<br />

8.24 million m 3<br />

Our total water consumption of 8.24 million<br />

cubic meters in <strong>2015</strong> was 16 percent less<br />

than in 2007.<br />

1.64l/l<br />

2007<br />

1.48l/l<br />

2010<br />

1.43l/l<br />

2011<br />

1.40l/l<br />

2012<br />

1.36l/l<br />

2013<br />

17% reduction since 2007<br />

1.36l/l<br />

2014<br />

1.35l/l<br />

<strong>2015</strong><br />

TARGET<br />

1.20l/l<br />

2020<br />

$543,000<br />

invested in water-reduction technologies<br />

in <strong>2015</strong>.<br />

1.35 liters per liter<br />

of water used to make each liter of product<br />

in <strong>2015</strong>.<br />

HOW WE’RE DOING IT<br />

We’re reducing the amount of water<br />

we use by:<br />

• Becoming more water-efficient<br />

• Treating and returning our wastewater<br />

• Investing in water-saving technology<br />

BECOMING MORE WATER-EFFICIENT<br />

Being water-efficient is key to our water<br />

stewardship strategy. In <strong>2015</strong>, our total<br />

water consumption was 8.24 million cubic<br />

meters (m 3 ), approximately 3 percent less<br />

than in 2014.<br />

We monitor our water efficiency by calculating<br />

our water use ratio – the amount of water we<br />

need to produce a liter of product. In <strong>2015</strong>, we<br />

used 1.35 liters/liter, down 17 percent since<br />

2007, against our 2020 target of 1.2 liters/liter. 1<br />

While we can’t reduce the amount of water<br />

in our products, we’ve made great strides<br />

in making our manufacturing and cleaning<br />

processes more water-efficient. In <strong>2015</strong>, we<br />

invested $543,000 in process optimization<br />

and water-saving technologies. But now that<br />

these investments have been made, each<br />

further step becomes more challenging.<br />

Future progress will depend increasingly<br />

on identifying locally led water saving<br />

opportunities and sharing best practices<br />

across CCE.<br />

As part of our drive for improvement, we<br />

operate company-wide water monitoring.<br />

Targets are set annually and opportunities<br />

to reduce water use are identified, modeled<br />

and reviewed by senior management.<br />

In <strong>2015</strong>, we again achieved the Carbon Trust<br />

Water Standard and our manufacturing<br />

operations at Dongen and Chaudfontaine<br />

retained the gold-level European Water<br />

Stewardship Standard. Issued under the<br />

European Water Framework Directive, the<br />

Standard recognizes excellence at every stage<br />

of water management – from the protection<br />

of water sources, through efficient use of<br />

water, to the quality of wastewater we release<br />

into the environment. The standard is granted<br />

for three years and confirmed each year by a<br />

follow-up audit. Plans are in place for other<br />

CCE sites to prepare for the requirements<br />

of the Directive.<br />

TREATING AND RETURNING<br />

OUR WASTEWATER<br />

We have high standards for all water returned<br />

to the environment – compliance with local<br />

regulations being the minimum requirement<br />

across CCE. We’re committed to continuing to<br />

ensure that 100 percent of our wastewater is<br />

safely returned to nature.<br />

While most of our manufacturing operations<br />

pre-treat wastewater on site and then send<br />

it to municipal water treatment plants, our<br />

manufacturing operations at Gent,<br />

Chaudfontaine, Wakefield 2 and Marseille<br />

FACTSHEET 19/32<br />

1 Data gathered through KORE management (The Coca-Cola<br />

Company internal standards) and ISO 14001 systems.<br />

2 Wakefield’s on-site wastewater treatment plant<br />

was operational until July <strong>2015</strong>. Wastewater from<br />

August-December <strong>2015</strong> was treated at municipal facilities.