JENOPTIK - VOTAN® BIM

JENOPTIK - VOTAN® BIM

JENOPTIK - VOTAN® BIM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

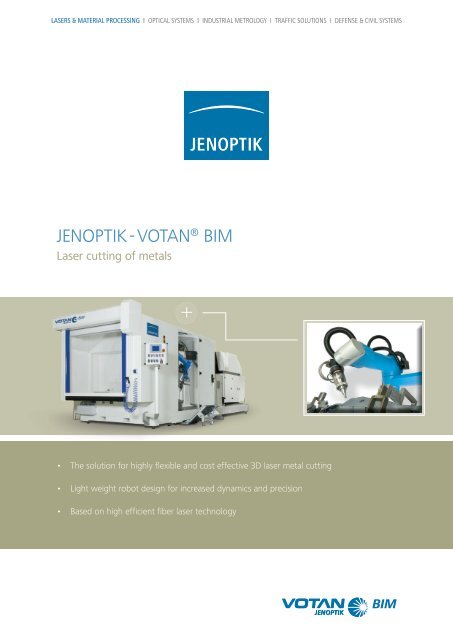

LASERS & MATERIAL PROCESSING I OPTICAL SYSTEMS I INDUSTRIAL METROLOGY I TRAFFIC SOLUTIONS I DEFENSE & CIVIL SYSTEMS<br />

<strong>JENOPTIK</strong> - VOTAN ® <strong>BIM</strong><br />

Laser cutting of metals<br />

• The solution for highly flexible and cost effective 3D laser metal cutting<br />

• Light weight robot design for increased dynamics and precision<br />

• Based on high efficient fiber laser technology<br />

<strong>BIM</strong>

Technology<br />

The system concept of <strong>JENOPTIK</strong> - VOTAN ® <strong>BIM</strong><br />

is a turn - key solution for 3D laser cutting of metals.<br />

The system has a mirror based and completely<br />

robot integrated beam guide. It allows handling up to<br />

4kW laser power without using a fiber in the working<br />

envelope of the laser robot. Thus taking advantage<br />

of the robots full capability in terms of dynamics and<br />

accessibility.<br />

Applications<br />

• Car body parts and<br />

structural components<br />

• Pipes and exhaust systems<br />

• Housings and appliances<br />

Merkmal <strong>JENOPTIK</strong> - VOTAN ® <strong>BIM</strong><br />

Laser type and output<br />

Reach processing area<br />

Repeat accuracy robot<br />

CO 2 laser ( wave length = 10.6 µm ) till 5 kW<br />

Fiber laser ( Wellenlänge @ 1.07 - 1.08 µm ) till 4 kW<br />

700 x 500 x 1400 mm<br />

± 0.1 mm<br />

Cutting speed up to 250 mm / s<br />

Beam guide mirror system integrated in robot<br />

Part handling Optional automatic loading or turntable<br />

Ambient conditions Processing temperatures 5to35°C<br />

Control<br />

Laser protection Class 1<br />

Features<br />

PLC S7 control<br />

Graphic user interface<br />

part handling round table or supporting table<br />

We reserve the right to make changes in the interest of technical progress.<br />

• Integrated beam guide: laser light directed by mirrors<br />

through the inside of the robot<br />

• Light weight robot design for higher accuracy, speeds<br />

and fast air moves<br />

• Slim cutting head design for higher accessibility<br />

• Compact overall system design<br />

• Capable of up to 4kW laser power: CO or fiber laser<br />

2<br />

• Reliability of over 200 high power laser processing<br />

systems in the field<br />

DE<br />

<strong>JENOPTIK</strong> I Lasers & Material Processing<br />

<strong>JENOPTIK</strong> Automatisierungstechnik GmbH<br />

2025.8<br />

Konrad - Zuse - Strasse 6 I 07745 Jena<br />

07.11<br />

Phone: + 49 36 41 65 - 2534 I Fax: + 49 36 41 65 - 2540<br />

E-Mail: info-lps.lm@jenoptik.com I www.jenoptik.com / lasermachines JO-AT