1/2011 - Jenoptik AG

1/2011 - Jenoptik AG

1/2011 - Jenoptik AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

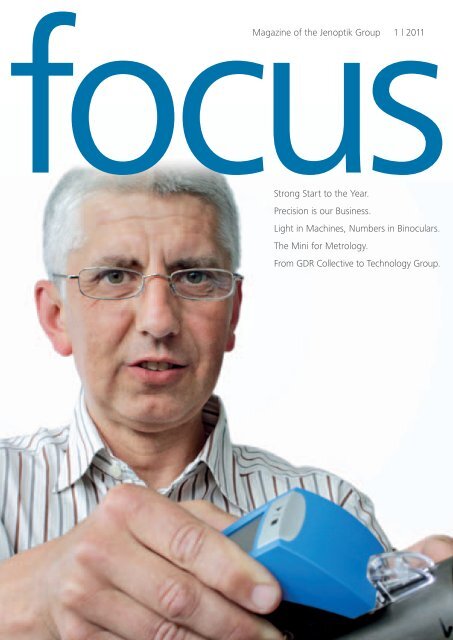

focus<br />

Magazine of the <strong>Jenoptik</strong> Group 1 l <strong>2011</strong><br />

Strong Start to the Year.<br />

Precision is our Business.<br />

Light in Machines, Numbers in Binoculars.<br />

The Mini for Metrology.<br />

From GDR Collective to Technology Group.<br />

1

Content<br />

Strong Start to the Year.<br />

After the successful fiscal year of 2010,<br />

<strong>Jenoptik</strong> closed the best first quarter in<br />

the company’s recent history with the<br />

1st quarter of <strong>2011</strong>.<br />

4 8 12<br />

Precision is our Business.<br />

The two <strong>Jenoptik</strong> divisions Industrial<br />

Metrology and Traffic Solutions are<br />

represented in Switzerland. Both focus<br />

on precise measurement.<br />

Light in Machines,<br />

Numbers in Binoculars.<br />

<strong>Jenoptik</strong> expands its product range<br />

of LEDs and increasingly offers final<br />

products for industrial customers.<br />

The Mini for Metrology.<br />

The Industrial Metrology division has<br />

launched a powerful mini-device for<br />

roughness measurement, the Hommel-<br />

Etamic W5.<br />

LEGAL NOTICE<br />

Publisher:<br />

JENOPTIK <strong>AG</strong>,<br />

Public Relations,<br />

D-07739 Jena,<br />

Phone +49(0)3641 65-2255,<br />

Fax +49(0)3641 65-2484<br />

Responsible: Katrin Lauterbach<br />

Editors: Katrin Lauterbach, Silvia Scharlock<br />

Editorial assistance:<br />

Jana Dichelle, Cornelia Ehrler<br />

2 3<br />

16<br />

From GDR Collective to<br />

Technology Group.<br />

18<br />

Twenty years ago, the foundation for<br />

today’s globally active <strong>Jenoptik</strong> was laid.<br />

A look back.<br />

Pictures:<br />

<strong>Jenoptik</strong><br />

Torsten Proß (page 3 right, page 20)<br />

SPECTARIS (page 15)<br />

fotolia.com (pages 8, 9, 11, 18/19, 22)<br />

Layout: Bernd Adam, Jena<br />

Print: Druckhaus Gera GmbH<br />

The contents of this magazine address men<br />

and women equally. For better readibility, the<br />

masculine forms are used normally.<br />

Publication in: June <strong>2011</strong>.

Katrin Lauterbach<br />

The restructuring of the last few years in all areas of the Group are<br />

now starting to pay off. At the same time, important target industries<br />

continued to develop positively. The <strong>Jenoptik</strong> Group recorded a jump<br />

in the Group EBIT of 11.8 million euros in the 1st quarter of <strong>2011</strong>.<br />

Strong Start to the Year:<br />

In <strong>2011</strong> <strong>Jenoptik</strong> recorded its best first quarter<br />

in the company’s recent history.<br />

”We expect this year to be the strongest for operating earnings<br />

since the disposal of M+W Zander five years ago. The quality of<br />

results is proof that we can reach our long-term profitability<br />

objectives,” says <strong>Jenoptik</strong> Chairman Dr. Michael Mertin of the<br />

quarterly figures published mid-May of this year. Just a few days<br />

earlier, <strong>Jenoptik</strong> had raised its forecast for Group EBIT for the<br />

full year from, originally, more than 35 million euros to the<br />

40 million euros now planned. ”We intensively discussed future<br />

business performance with our segments in extensive strategy<br />

meetings,” says Michael Mertin on the forecast increase.<br />

This increase was made based on the discussions and due to<br />

the very good order and earnings development in the 1st quarter<br />

of <strong>2011</strong>. Group EBIT of 40 million euros is an increase of more<br />

than 35 percent over the comparable figure for 2010, which<br />

was at 29.0 million euros. From as early as 2010, <strong>Jenoptik</strong> had<br />

benefited from the sustained and rapid recovery in its two<br />

main target industries, the semiconductor and the automotive<br />

industries. This trend continued during the first months of <strong>2011</strong>.<br />

For <strong>Jenoptik</strong>, the Group EBIT in the 1st quarter of 11.8 million<br />

euros primarily reflects the currently very high level in the<br />

semiconductor cycle. ”You are no prophet if you forecast a<br />

normalization during the course of the year,” says Michael<br />

Mertin. He also cautioned that the quarterly EBIT of 11.8 million<br />

euros could not be extrapolated one-to-one for the entire fiscal<br />

year.<br />

Sales and employment growth,<br />

especially abroad.<br />

In <strong>2011</strong>, sales are expected to rise from 478.8 million euros in<br />

2010 (without Jena-Optronik GmbH) to more than 510 million<br />

euros. Strong sales are anticipated in the Lasers & Optical<br />

Systems and Metrology segments in <strong>2011</strong>. Both segments were<br />

already sales drivers in the 1st quarter of <strong>2011</strong>, in which sales<br />

increased by 16.5 percent over the prior year’s quarter to<br />

124.5 million euros.<br />

In both 2010 as well as the 1 st quarter of <strong>2011</strong>, sales<br />

growth came primarily from abroad. For instance, sales<br />

in North America (NAFTA) rose by just under 15 percent<br />

in the 1st quarter of <strong>2011</strong> and by almost 52 percent in<br />

Asia. In Europe, sales volumes also increased by more<br />

than 40 percent compared to the same period last year<br />

due to the booming semiconductor industry, while<br />

sales in Germany declined slightly. <strong>Jenoptik</strong> is present<br />

in more than 70 countries and is focusing on future<br />

growth primarily through further internationalization.<br />

The key target areas are North America and Asia. So,<br />

after <strong>Jenoptik</strong> Korea in 2009, another majority stake<br />

was established in Asia in 2010 – <strong>Jenoptik</strong> Japan. In the<br />

USA, <strong>Jenoptik</strong> has invested in new production equipment<br />

at its Optics locations.<br />

”Considering the sales trend abroad, we will primarily<br />

recruit new employees also in those regions,” summarized<br />

Michael Mertin regarding questions on a planned<br />

rise in employees in Germany. ”Our German sites will<br />

also grow, but probably not as rapidly as overseas.”<br />

Overall, the workforce should rise slightly in <strong>2011</strong>, but<br />

not analogous to the increase in sales. This trend has<br />

already underpinned the development of the 1st quarter<br />

of <strong>2011</strong>: Consolidated sales rose by 16.5 percent with<br />

an almost constant workforce of 2,956.<br />

The fiscal year of 2010 at a glance<br />

Continuing BD Change comp.<br />

(Figures in million euros) 2010 Group 2) 2010 Group 2009 to Group in %<br />

Sales 478.8 510.6 473.6 7.8<br />

Lasers & Optical Systems 188.9 188.9 166.7 13.3<br />

Metrology 113.8 113.8 96.0 18.5<br />

Defense & Civil Systems 173.9 205.8 205.3 0.2<br />

Others 1) 2.2 2.1 5.6 – 62.5<br />

EBIT 29.0 56.4 – 19.6 ++<br />

Lasers & Optical Systems 13.3 13.3 – 16.5 ++<br />

Metrology 8.6 8.6 – 14.6 ++<br />

Defense & Civil Systems 8.6 11.5 12.2 – 5.7<br />

Others 1) – 1.5 23.0 – 0.7 ++<br />

Earnings before tax 15.0 42.5 – 34.3 ++<br />

Earnings after tax 9.0 36.4 – 33.9 ++<br />

Order intake 534.6 582.5 432.8 34.6<br />

Lasers & Optical Systems 230.2 230.2 168.4 36.7<br />

Metrology 137.0 137.0 83.2 64.7<br />

Defense & Civil Systems 163.7 211.6 178.0 18.9<br />

Others 1) 3.7 3.7 3.2 15.6<br />

Continuing BD Group without Optronik Change<br />

(Figures in million euros) at 31.12.2010 at 31.12.2009 in %<br />

Order backlog 355.4 304.0 16.9<br />

Lasers & Optical Systems 98.8 59.9 64.9<br />

Metrology 45.1 21.9 105.9<br />

Defense & Civil Systems 212.6 224.8 – 5.4<br />

Others 1) – 1.1 – 2.6 57.7<br />

Employees (31.12. incl. trainees) 2,951 3,138 – 6.0<br />

Lasers & Optical Systems 1,234 1,184 – 3.9<br />

Metrology 632 769 – 17.8<br />

Defense & Civil Systems 931 947 – 1.7<br />

Others 1) 154 138 11.6<br />

1) Others includes holding, SSC, real-estate, consolidation.<br />

2) Group with Jena-Optronik GmbH.<br />

BD = Business Division<br />

4 5

<strong>Jenoptik</strong> in Japan.<br />

In November 2010, <strong>Jenoptik</strong> expanded its presence<br />

in Japan together with longtime partner Kantum<br />

Electronics Co. Ltd. The joint venture by <strong>Jenoptik</strong> and<br />

Kantum, founded in 2005 and specializing mainly in<br />

the sale of diode lasers, is now called JENOPTIK Japan<br />

Co. Ltd and is open to all Group divisions. Sales was<br />

extended to other Group products and <strong>Jenoptik</strong> has<br />

since become the majority shareholder with an almost<br />

two-thirds majority.<br />

All <strong>Jenoptik</strong> employees and their families survived the<br />

terrible earthquake in Japan without health consequences.<br />

The business premises also remained intact.<br />

A crisis committee was established where, to this day,<br />

all information is brought together. ”Our Japan business<br />

is still in its infancy. In 2010, it amounted to about<br />

1 percent of sales,” says <strong>Jenoptik</strong> Chairman Michael<br />

Mertin. The procurement volume from Japan was<br />

slightly more than 1 percent of the Group’s total<br />

volume in 2010 so, even here, no large direct effects<br />

are expected and also did not occur until May.<br />

”It remains to be seen how the situation will evolve<br />

and we will constantly evaluate what is guaranteed by<br />

our central procurement management,” says Michael<br />

Mertin.<br />

Sale of Jena-Optronik GmbH.<br />

As part of the consolidation of the European space<br />

market, in December 2010 <strong>Jenoptik</strong> sold all shares of<br />

the subsidiary Jena-Optronik GmbH to Astrium GmbH,<br />

an EADS Group company. The <strong>Jenoptik</strong> Group’s space<br />

business was bundled in Jena-Optronik GmbH, which<br />

contributed about 30 million euros to sales of the<br />

<strong>Jenoptik</strong> Group. <strong>Jenoptik</strong> acquired a majority holding<br />

of Jena-Optronik GmbH in 2003 and increased the<br />

share to 100 percent in 2004. The business was<br />

expanded and Jena-Optronik developed into a world<br />

market leader in specialized areas of satellite<br />

technology while the company’s sales had nearly<br />

doubled since then. “For Jena-Optronik GmbH, we<br />

expect better growth opportunities in the future<br />

through being part of a global system supplier and<br />

specialists in aerospace such as EADS,” says Michael<br />

Mertin. The <strong>Jenoptik</strong> Group used the cash inflow after<br />

conclusion of the sale in December 2010 to significantly<br />

reduce net debt.<br />

A sound financial position:<br />

Net debt now “only” 73.5 million euros.<br />

In 2010, the key figures of the <strong>Jenoptik</strong> Group were chiefly defined by the<br />

sale of Jena-Optronik GmbH. Group EBIT, in particular, was positively<br />

impacted by the sale proceeds. This was 56.4 million euros, including the<br />

one-off effects of the sale. The sale – in addition to the positive cash flow<br />

resulting from consistent receivables and inventory management and the<br />

capital increase in March 2010 – also contributed to a halving of net debt to<br />

79.3 million euros at the end of <strong>2011</strong> (159.5 million euros at the end of<br />

2009). In the 1st quarter of <strong>2011</strong>, it fell again by 7.3 percent to 73.5 million<br />

euros. ”We have worked intensely on this key company figure for financial<br />

stability in the past two years,” says Chief Financial Officer Frank Einhellinger.<br />

“Our focus on positive cash flows has particularly proven itself,” summarized<br />

the CFO. The main driver is Working Capital Management with the objective<br />

of “tieing up” the least amount of financial resources possible – whether in<br />

production material in the Group’s storerooms or as products or processed<br />

products not yet with the customer. This requires efficient processes in order<br />

to reduce storage and processing times. “We are working on this in many of<br />

our <strong>Jenoptik</strong> Excellence Program projects, which went into its third year in<br />

<strong>2011</strong> with projects in all areas of the Group,” says Frank Einhellinger.<br />

Increase in sales by region<br />

NAFTA<br />

16.9m euros<br />

(+14.9 %)<br />

Europe<br />

42.9m euros<br />

(+40.3 %)<br />

Order situation remains positive.<br />

Germany<br />

48.9m euros<br />

(–0.9 %)<br />

Others<br />

4.5m euros<br />

(–8.5 %)<br />

In 2010, the <strong>Jenoptik</strong> Group was able to report order intakes that were about<br />

23 percent higher than 2009. The strong growth to 534.6 million euros<br />

(previous year, 432.8 million euros) resulted from the economic recovery as<br />

well as several large orders that <strong>Jenoptik</strong> was able to book. These included<br />

an order for medical lasers in the USA, a large order from abroad for traffic<br />

Asia<br />

12.2m euros<br />

(+51.6 %)<br />

The growth in Group sales by 16.5 percent in the 1 st quarter of <strong>2011</strong> came completely from abroad.<br />

solutions technology, as well as the order for the next tranche<br />

of Eurofighter Radom and the energy supply for PATRIOT<br />

anti-missile systems in the Defense & Civil Systems division.<br />

Both trends continued in the first months of the current fiscal<br />

year – a good economic situation with overall high order<br />

intakes, especially from the semiconductor and automotive<br />

industries, as well as the aforementioned large orders on top.<br />

In the 1 st quarter of <strong>2011</strong>, order intake was 172.6 million euros,<br />

surpassing the prior year’s quarter by 36.4 percent. Included is<br />

the large partial order for the PUMA armored fighting vehicle<br />

at just under 40 million euros in the Defense & Civil Systems<br />

segment. Another large partial order for the PUMA is expected<br />

in the coming months. In May, <strong>Jenoptik</strong> was able to announce a<br />

large order of more than 20 million euros from Saudi Arabia in<br />

the Traffic Solutions division, which will also impact on the order<br />

intake in the current 2nd quarter of <strong>2011</strong>. Several hundred stationary<br />

systems for recording red light and speed violations will<br />

be delivered and installed through this year and the next. As a<br />

result, the order will in part contribute to sales and earnings in<br />

<strong>2011</strong>.<br />

Long-term goals remain.<br />

”Above all, the order development of recent months and the<br />

continuing strong economy are encouraging for the whole of<br />

<strong>2011</strong>,” concludes Michael Mertin. Although the very good 1st quarter for <strong>Jenoptik</strong> reflects the currently very high level in the<br />

semiconductor cycle and management is anticipating a normalization<br />

during the course of the year, the automotive industry,<br />

medical technology, photovoltaics and the transport and<br />

security areas are further drivers of the expected positive<br />

development beyond <strong>2011</strong>. “Our earnings in the 1st quarter of<br />

<strong>2011</strong>, with an EBIT margin of 9.5 percent, shows that we can<br />

achieve our medium-term profitability targets – a Group-wide<br />

EBIT margin of 9 to 10 percent,” says Michael Mertin.<br />

”We don’t want to grow at all costs, but profitably while<br />

maintaining intrinsic value,” comments the <strong>Jenoptik</strong> Chairman<br />

on questions of possible acquisitions. Acquisitions have to move<br />

us forward, be it on the market, technology or product side or<br />

in a specific region. The financial resources resulting from the<br />

measures in 2010 and the continued positive cash flow from<br />

operating activities open attractive opportunities for organizational<br />

growth and acquisitions.<br />

The months January until March at a glance<br />

Group Group 2) Change<br />

(Figures in million euros) Jan.–March <strong>2011</strong> Jan.–March 2010 in %<br />

Sales 124.5 115.2 16.5<br />

Lasers & Optical Systems 56.1 45.2 24.1<br />

Metrology 28.0 20.0 40.0<br />

Defense & Civil Systems 40.0 49.9 – 3.8<br />

Others 1) 0.4 0.1 ++<br />

EBIT 11.8 4.0 ++<br />

Lasers & Optical Systems 10.2 3.9 ++<br />

Metrology 1.0 – 1.0 ++<br />

Defense & Civil Systems 1.1 1.7 10.0<br />

Others 1) – 0.5 – 0.6 0<br />

Earnings before tax 9.3 0.7 ++<br />

Earnings after tax 7.5 0.4 ++<br />

Order intake 172.6 145.6 36.4<br />

Lasers & Optical Systems 61.1 56.2 8.7<br />

Metrology 38.0 40.4 – 5.9<br />

Defense & Civil Systems 73.7 48.8 148.1<br />

Others 1) – 0.2 0.2 ++<br />

Group Group 2) Change<br />

(Figures in million euros) March 31, <strong>2011</strong> Dec. 31, 2010 in %<br />

Order backlog 398.1 355.4 12.0<br />

Lasers & Optical Systems 101.6 98.8 2.8<br />

Metrology 51.9 45.1 15.1<br />

Defense & Civil Systems 246.4 212.6 15.9<br />

Others 1) – 1.8 – 1.1 ++<br />

Employees (incl. trainees) 2,956 2,951 0.2<br />

Lasers & Optical Systems 1,240 1,234 0.5<br />

Metrology 633 632 0.2<br />

Defense & Civil Systems 930 931 – 0.1<br />

Others 1) 153 154 – 0.6<br />

1) Others includes holding, SSC, real-estate, consolidation.<br />

2) Group without Jena-Optronik GmbH<br />

Note: For the <strong>2011</strong> financial reporting all Jena-Optronik GmbH key figures have been excluded<br />

for 2010 so that the <strong>2011</strong> figures are fully comparable with those of 2010.<br />

On the question of the distribution of a dividend, Michael<br />

Mertin explains: ”Solid equity capital is vital for sustainable<br />

growth, particularly for technology companies.” In addition to<br />

replacing existing financing, future dividends would also depend<br />

on the extent to which <strong>Jenoptik</strong>’s liquidity could be sensibly<br />

invested in growth and acquisitions. ”However, we obviously<br />

want to reach a position where we are able to pay dividends,”<br />

says the <strong>Jenoptik</strong> Chairman.<br />

www.jenoptik.com<br />

katrin.lauterbach@jenoptik.com<br />

6<br />

7

Cornelia Ehrler<br />

Switzerland stands for much that is characterized by quality,<br />

taste and tradition. Just think of culinary delights such as Swiss<br />

cheese, raclette and rosti. Or Swiss chocolate – many pioneers<br />

of chocolate production were located in Switzerland, such as<br />

Rodolphe Lindt, inventor of “conching”, which makes chocolate<br />

creamy; Philippe Suchard, inventor of the “Milka” brand, and<br />

Theodor Tobler, who invented ”Toblerone” in 1908 and which<br />

is still produced exclusively in Bern, the Swiss capital.<br />

Switzerland is eponymous for landscapes reminiscent of rocky<br />

or sandy mountains and lakes. In Germany alone there are more<br />

than 60 of these Swiss landscapes such as Saxon Switzerland,<br />

with the Elbe Sandstone Mountains.<br />

Switzerland also stands for money. According to statistics from<br />

the International Monetary Fund, the Alpine country regularly<br />

belongs to the five wealthiest countries in the world according<br />

to its gross domestic product per capita. In the “Global Competitiveness<br />

Index 2010 – <strong>2011</strong>” at the Geneva World Economic<br />

Forum, which evaluates the competitiveness of a country,<br />

Switzerland is once again in first place, followed by Sweden,<br />

Singapore, the United States – and Germany in fifth place.<br />

Precision<br />

Switzerland is different, but neutral.<br />

Switzerland seems to be different, a special case in the middle<br />

of Europe. A country with four official languages, including<br />

Rhaeto-Romanic, spoken by only 0.5 percent of the population<br />

in the canton of Grisons. Politically, too, Switzerland is different,<br />

as the history of the Confederates, marked by wars and myths<br />

surrounding the autonomy of the cantons, such as the Rütlischwur<br />

(Rütli oath), gave rise to a unique political formation.<br />

Founded as a loose confederation of states, the current federal<br />

state with the official designation of ”Swiss Confederation”<br />

differs from other republics worldwide. The 26 cantons are<br />

living a distinctive federalism. Citizens have a direct influence on<br />

government action through elements of direct democracy such<br />

as referendums and initiatives. And the “perpetually armed”<br />

neutrality in foreign policy is a constitutional principle, which<br />

excludes membership in military alliances such as NATO.<br />

Despite this, Switzerland has an army, no, Switzerland is an army,<br />

as the saying goes. Although only five percent of Army personnel<br />

are regular soldiers, the rest are conscripts, but they keep their<br />

personal equipment, including weapon, at home. Swiss citizens<br />

are prohibited from serving in a foreign army. The exception is the<br />

Swiss Guard which has been responsible since 1506 for the<br />

protection of the Pope as ”house police” – not as an army.<br />

Switzerland is known for utmost precision. No wonder<br />

that two <strong>Jenoptik</strong> divisions, which are both very precise,<br />

are represented in the Confederation: Industrial Metrology<br />

with Hommel-Movomatic Suisse SA and Traffic Solutions<br />

with Multanova <strong>AG</strong>.<br />

is our Business.<br />

The Swiss government, the Federal Council with seven members, is tradition-<br />

ally regarded as the most stable executive authority in the world. Equally<br />

reliable are the conditions for foreign employers who appreciate the high<br />

productivity and excellent infrastructure in Switzerland. Some 1,200 German<br />

companies employ about 107,000 people in Switzerland through subsidiaries,<br />

sales offices or investment holdings. <strong>Jenoptik</strong> is one of these companies; its<br />

two subsidiaries from the Metrology segment live the traditional Swiss<br />

understanding of precision:<br />

Precision is our business.<br />

The <strong>Jenoptik</strong> Industrial Metrology division has a presence in Switzerland with<br />

its subsidiary Hommel-Movomatic Suisse SA. <strong>Jenoptik</strong> acquired the French<br />

metrology specialists ETAMIC SA in 2006, which had already included Swiss<br />

Movomatic SA since 1993. In 2007, the Etamic-Movomatic Group was merged<br />

worldwide with the <strong>Jenoptik</strong> subsidiary Hommelwerke GmbH in Villingen-<br />

Schwenningen to Hommel-Etamic.<br />

The Swiss team of Hommel-Movomatic Suisse SA currently has about 30<br />

employees at the Peseux location on the shores of Lake Neuchâtel in the<br />

north-western canton of Neuchâtel. The origin of Movomatic lies in the<br />

so-called “Watch Valley” between Basel and Geneva. In 1937, in this area<br />

characterized by watch making and precision mechanics, the company<br />

”Motomechanik” was founded in Inkwil which, a few years later in 1950,<br />

specialized in ”in-process metrology”, i.e. in measurement technologies that<br />

Switzerland and money.<br />

It is also the sums of money in Swiss banks that are<br />

notorious; Credit Suisse is probably the most recognized<br />

bank. The almost mythically inflated Swiss banking secret<br />

has now been somewhat superseded by the cooperation<br />

between Germany and Switzerland in tax matters:<br />

In October 2010, both countries signed a protocol on a<br />

double taxation agreement, which governs the exchange<br />

of information between the two countries. In addition,<br />

a withholding tax for the accounts of foreign customers<br />

is planned, which is to be transferred to the countries of<br />

origin of the bank customers.<br />

Even more problematic is how to deal with so-called potentate<br />

funds, money from dictators, which usually stems<br />

from corruption or other shady sources. The government<br />

recently barred the assets assigned to the recently<br />

deposed Egyptian head of government Mubarak, Ben<br />

Ali of Tunisia and the Libyan ruler Gaddafi by emergency<br />

decree in Bern. Overall, these potentate assets from<br />

North Africa are believed to amount to 830 million francs<br />

(approx. 660 million euros). Since the late 1990s, in<br />

order to combat financial crime, Switzerland has drafted<br />

anti-money laundering laws, which impose special duties<br />

of care on Swiss banks. According to the Swiss Foreign<br />

Ministry, in the past 15 years Switzerland has been able<br />

to return 1.2 billion euros of confiscated dictator funds to<br />

the respective countries of origin.<br />

8 9

Economic relations between Germany and Switzerland.<br />

For Switzerland, Germany is traditionally by far its most important trading<br />

partner, ahead of Italy, France and the United States. Almost 20 percent of<br />

all Swiss exports went to Germany in 2009, primarily machinery, pharmaceutical<br />

products and precious metals. In 2009, the share of imports from<br />

Germany to Switzerland stood at 33 percent, including machinery, motor<br />

vehicles and mineral fuels.<br />

The importance of Switzerland for German foreign trade outside the<br />

European Single Market is exceeded only by the USA and China. In 2010,<br />

the Alpine country was ranked 9th in German foreign trade for imports<br />

and exports.<br />

The strongest export sectors of the Swiss Confederation are the chemical<br />

and pharmaceutical industries, the watch and metal industries as well as the<br />

Precision in metrology: Hommel-Movomatic Suisse SA<br />

manufactures, amongst others, gauge heads for the<br />

control of diameter and position in grinding machines.<br />

www.auswaertiges-amt.de Bilateral relations<br />

www.swissworld.org/de<br />

www.multanova.ch<br />

info.ch@hommel-movomatic.com<br />

machinery and electronics industries, precision instruments and apparatus<br />

and automotive supplies.<br />

Like Germany, Switzerland is represented in many international organizations<br />

such as the OECD, the International Monetary Fund and the World Trade<br />

Organization (WTO). In addition, Switzerland is a founding member of the<br />

European Free Trade Association (EFTA). In contrast, the country is not a<br />

member of the EU or NATO. Nevertheless, there are “Bilateral Agreements”<br />

between Switzerland and the EU to simplify economic exchanges, as well as<br />

“NATO’s Partnership for Peace.” Switzerland has also been a member of the<br />

United Nations (UN) since a referendum in 2002.<br />

Source: Federal Foreign Office, Federal Statistical Office<br />

are already used during the manufacturing process. By 1953,<br />

the company presented the world’s first in-process measuring<br />

head for measurement control for cylindrical grinding machines.<br />

Even today, the core competence of Hommel-Movomatic Suisse<br />

SA lies in the tactile in-process metrology. It develops and<br />

produces measurement control systems that are part of the<br />

preferred equipment of grinding machines and are installed on<br />

machine tools. In particular, globally active manufacturers of<br />

high-precision components for injection and hydraulic engineering<br />

and customers from quality-sensitive markets such as the<br />

USA, Japan and Central Europe as well as from the so-called<br />

emerging markets such as India and China appreciate these<br />

measuring devices with Swiss precision.<br />

Who invented it? Pioneers in speed surveillance.<br />

The Swiss colleagues at Multanova <strong>AG</strong> are just as precise in<br />

speed surveillance. Multanova <strong>AG</strong> has been a part of the<br />

present day <strong>Jenoptik</strong> Traffic Solutions division since 1999 when<br />

<strong>Jenoptik</strong> acquired the then ROBOT Visual Systems GmbH in<br />

Monheim/Düsseldorf including Multanova. The Swiss traffic<br />

controllers are considered pioneers in their field: Multanova is<br />

the first company to have developed and manufactured radar<br />

devices in Switzerland. As early as 1952, during the founding<br />

year, it presented a radar system for speed surveillance with<br />

photographic registration.<br />

Facts and Figures about Switzerland<br />

Name of the country: Swiss Confederation,<br />

CH = Confoederatio Helvetica<br />

Capital city: Bern<br />

Area: 41,285 square kilometers<br />

Population: 7.78 million,<br />

of these 264,000 Germans<br />

Languages: 4 official languages: German<br />

(ca. 64 per cent), French (ca. 20 per cent),<br />

Italian (6.5 per cent), Rhaeto-Romanic<br />

(0.5 per cent); other languages (9 per cent)<br />

Religions: Catholic Church (42 per cent),<br />

Protestant (35 per cent), non-denominational<br />

(11 per cent), Islam, orthodox Christianity<br />

National day: August 1<br />

Form of government: democratic and<br />

republican federal state<br />

Today, Multanova is a leader in mobile and stationary traffic<br />

surveillance in sales, support and as a system integrator for the<br />

<strong>Jenoptik</strong> Traffic Solutions division. In Uster, in the canton of<br />

Zurich, in the north-eastern part of Switzerland, about 15<br />

employees distribute, install and manage monitoring systems<br />

that are based on current measurement technologies such as<br />

radar or laser, piezo or induction technology. The classic is still<br />

the Multanova 6F radar, which was introduced by the Swiss in<br />

1984, has been constantly modernized since then, and is now<br />

used worldwide in places such as Spain, Australia and Canada.<br />

The Swiss also install and maintain surveillance systems such as<br />

the TraffiPatrol or the TraffiSection systems. The latter is a new<br />

traffic surveillance system that measures average speed along a<br />

stretch. The Traffic Solutions division successfully placed the<br />

system, optionally combinable from mobile or stationary units,<br />

Head of State: collective 7-member Federal Council,<br />

duty of President rotating every year; President in<br />

<strong>2011</strong>: Micheline Calmy-Rey<br />

Head of Government: not required because<br />

the head of the Federal Council is the President<br />

Administrative structure: expressly federalist state<br />

of 20 cantons and 6 half-cantons with strong cantonal<br />

competencies<br />

Currency: Swiss franc (CHF)<br />

Gross domestic product (GDP) 2010:<br />

ca. 550 billion CHF (ca. 400 billion euros)<br />

Per capita GDP (2010):<br />

71,500 CHF (ca. 52,000 euros)<br />

Source: Federal Foreign Office, March <strong>2011</strong><br />

on the market with a large order in February 2010, in Switzerland<br />

and other markets. The Alpine country was also the center<br />

of innovative traffic solutions technology in the fall of 2010.<br />

Multanova presented the new 3D tracking radar in Geneva,<br />

which can simultaneously record and track up to 32 vehicles on<br />

different lanes.<br />

”Made in Switzerland” innovations – the Swiss Confederation is<br />

also a source of productivity and quality for <strong>Jenoptik</strong>. Esteemed<br />

for their economy and political neutrality, Switzerland seems to<br />

remain different. A final example? The Swiss were the first<br />

people in the world allowed to vote on accession to the United<br />

Nations (UN). In 2002, Switzerland became the only UN country<br />

with a square flag. But the UN rules require that flags which fly<br />

at the UN headquarters must be rectangular. The compromise:<br />

The total area of the square flag may not exceed that of the<br />

other rectangular flags. So, the Swiss flag, white cross on red<br />

background, now also flies at the UN headquarters in New York.<br />

Precision for more road safety: Multanova <strong>AG</strong><br />

is the leading provider of mobile and stationary<br />

traffic monitoring in Switzerland.<br />

10 11

Jana Dichelle<br />

Lighting with light diodes – this is a market that is only just<br />

starting to flourish. As recently as 2007, there were small niches<br />

that could be served with high-performance LEDs, such as<br />

traffic light illumination or decorative lighting. Market observers<br />

such as Databeans are predicting double-digit growth rates in<br />

the coming years.<br />

Triptis: LED instead of neon<br />

<strong>Jenoptik</strong> operates at the center of this market, which does not<br />

just bring conventional lighting manufacturers onto the scene<br />

but also optical and electronics companies. And the components<br />

that <strong>Jenoptik</strong> manufactures in this area are being increasingly<br />

joined by final products. Mathias Goebel, responsible for<br />

LED sales in the Optoelectronics Systems business unit of<br />

<strong>Jenoptik</strong> in Triptis (Thuringia), has just returned from the trade<br />

fair Transport Logistic in Munich. There, he presented an LED<br />

lighting system for high bay warehouses.<br />

Picture at the top: The LED module (below) and the corresponding<br />

optics device (top) – when mounted together, they illuminate the<br />

interior of machines in white light.<br />

”In these types of warehouses you need light in the hallway and<br />

it needs to give light where you need it. We convinced everyone<br />

with our light distribution.” In addition, there are the potential<br />

savings: ”You either need less energy than for conventional light<br />

sources, or you get more light at the desired location for the<br />

same energy input,” explains Mathias Goebel. An important<br />

market for this is the logistics and transport industry, in which<br />

companies want to act under the banner of Green Logistics and<br />

Sustainability.<br />

White light from a new partnership<br />

The white LEDs, for the illumination of storage rooms, are<br />

manufactured by the company LEIDS GmbH & Co. KG with<br />

which <strong>Jenoptik</strong> has recently started cooperating. LEIDS is a<br />

distribution partner of the company Alder from Taiwan and<br />

supplies <strong>Jenoptik</strong> with white LEDs. <strong>Jenoptik</strong> develops the optics:<br />

Since LEDs scatter rays in all directions the light must be shaped<br />

and directed. Corresponding optics are developed in Triptis, first<br />

in the optics design program on the computer in order to subsequently<br />

be produced in the injection molding procedure. “If<br />

the right electronics and mechanics are complemented by highperformance<br />

optics, this leads to excellent light solutions,” says<br />

Mathias Goebel.<br />

LED experts in Triptis and Berlin are operating in<br />

an emerging market – and are bringing a few things<br />

to light.<br />

Light in Machines,<br />

Numbers in Binoculars<br />

Illuminating plant and storage facilities, machinery and machine<br />

interiors – that’s the world in which the Optoelectronics Systems<br />

business unit of <strong>Jenoptik</strong> is becoming increasingly active with<br />

the LED modules. The field of machinery lighting emerged as a<br />

result of an inquiry from a large company that specializes in<br />

industrial electrical engineering. Its customers wanted lighting,<br />

and <strong>Jenoptik</strong> came on board for its development and manufacture.<br />

Reception for LED<br />

In the future, LEDs will also play an important role in the office<br />

environment. <strong>Jenoptik</strong> will shortly launch this in-house: From<br />

July this year – and in time for the 20-year <strong>Jenoptik</strong> anniversary<br />

– LED lighting systems will illuminate the reception of the<br />

<strong>Jenoptik</strong> rotunda in the technology center in Jena. The modules<br />

are currently being assembled in Taiwan. ”Perspectively,” reveals<br />

Mathias Goebel, ”<strong>Jenoptik</strong> could also operate in assembly, as all<br />

necessary requirements are present in Triptis.”<br />

This also includes the light subsystem jointly developed with<br />

Lumenova called Lumenova® Light Engine, which is primarily<br />

used in public spaces. In Jena, Esslingen and at highway rest<br />

areas there are already road sections illuminated at night by<br />

white LED light – energy-efficient, precisely targeted and<br />

there fore free from light pollution. In addition, LED lamps are<br />

insect-friendly as the light contains neither infrared nor ultraviolet<br />

light components, which insects otherwise find so<br />

appealing.<br />

Produced in cooperation with LEIDS GmbH:<br />

a lighting system for a lucid high bay –<br />

for light where it is needed.<br />

12 13

Light diodes<br />

LED stands for light-emitting diode, whose light originates from a<br />

silicon semiconductor crystal. Silicon as such would not conduct<br />

electricity well, that is why it is doped with gallium, indium or phosphor.<br />

When power is applied, electrons flow through the crystal<br />

lattice and, in a sense, push the impurity atoms. In this process, the<br />

impurity atoms absorb energy, briefly get to a higher energy level in<br />

order to return to the stable lower energy level a moment later. The<br />

energy absorbed is emitted in the form of photons as light wave. No<br />

heat is caused in this process; almost all of the energy is transformed<br />

into light.<br />

A customized LED module:<br />

The wavelengths in which <strong>Jenoptik</strong> produces<br />

LEDs are between 360 and 1750 nanometers.<br />

The seven-segment display: on the right, a conventional<br />

display, on the left, the new lightbars – brighter<br />

and more economical in power consumption.<br />

The illustration (right) shows the design of the<br />

seven-segment display.<br />

Berlin: Intensely luminous signs<br />

From Triptis to Berlin where Dr. Bernd Kloth pleads, not entirely<br />

seriously, for the good old digital watch to be issued with light<br />

diodes. Because the first LED technology of the early 1980s was<br />

glowing numbers on the first calculators or digital watches.<br />

”They were replaced by LCD everywhere, above all, because the<br />

batteries were used up so quickly,” he recalls of the shift to the<br />

dark gray on light gray colored displays that dominate today.<br />

The battery problem has now been eliminated as the new LED<br />

display chips are 100 times more efficient than those previously<br />

and power consumption lower by the same amount. So they<br />

have become suitable for all types of portable devices for<br />

illuminating any numbers, letters and symbols. ”As the power<br />

distribution on the chip is now more even, an attractive light<br />

image emerges.”<br />

<strong>Jenoptik</strong> has, in the meantime, secured a unique position for the<br />

display chips, in particular concerning the dynamics, assesses<br />

the Product manager. In this case, dynamics stands for how<br />

diversely the brightness can be adjusted. The chips from Berlin<br />

are true all-rounders in the field: They can be adjusted as<br />

needed, dimmed down at night or set very bright during snow<br />

or bright sunshine. This is very useful, for example, in measuring<br />

instruments such as rangefinders. They measure distances by<br />

optical means, and the measured value is reflected in the optics.<br />

This requires that the chips be very small as ”in optics there is<br />

always very little space,” says the LED expert.<br />

Optics manufacturers are knocking<br />

Two factors, estimates Bernd Kloth, have contributed to this LED<br />

leap in quality, “on the one hand our years of experience and,<br />

on the other, the progress in material development, the epi-<br />

taxy.” Epitaxy – this is the method of growing crystals as de -<br />

sired. The crystalline material does not originate at <strong>Jenoptik</strong>, but<br />

is bought and processed into display or point source chips. The<br />

interest of optics manufacturers is huge: ”Companies that have<br />

seen our new LED in the optical devices of our customers are<br />

now contacting us,” says the Product manager.<br />

In his view, there are not necessarily new applications for the<br />

LEDs, which beam red at 650 nanometers: “They’re actually<br />

already there; it’s just that the quality is better.” In addition to<br />

range finders and distance measuring apparatus this also<br />

includes binoculars as well as medical and sports medical<br />

devices such as microscopy and the reflection of information in<br />

glasses – present wherever numbers, letters and symbols are to<br />

be displayed on the smallest possible area. “Maybe,” he muses,<br />

”it’s time to reconsider whether LED displays do represent an<br />

alternative to LCD in one way or another after all. In any case,<br />

power consumption is small, especially if LCD displays are<br />

actively illuminated. And brightness can be varied better for<br />

LEDs as active beams.”<br />

Points with point sources<br />

In another area the Berliners are not alone, but have now drawn<br />

level with the best: Based on the same technology – LED with<br />

high dynamics – LED point sources with emission spot diameters<br />

of 25 to 250 micrometers have been developed, whose light<br />

intensity is five times greater than that of the previous generation.<br />

Their emission area can be easily focused and is circular<br />

and their lifespan is around 100,000 hours. Taken together, the<br />

properties are useful for rotation sensors with which to calculate<br />

positions or angles, for optical sights as a miniature light point,<br />

for light barriers as a focused beam and for printers in line<br />

arrays. Even here most applications already exist. “At best, it<br />

could be, for example, that a light barrier becomes suitable for<br />

wider doors than before, as the beam safely bridges the<br />

distance,” feels Bernd Kloth.<br />

However, these red LED point sources are also coming into<br />

question for data transmission. Their switching times, at less<br />

than five nanoseconds, are very short, while the current<br />

handling capacity is particularly high. And finally, the homogeneous<br />

image area and high light intensity is good for replacing<br />

semiconductor lasers in a variety of sensory applications. So,<br />

a quality leap that may have far-reaching consequences.<br />

www.jenoptik.com<br />

sales-oes@jenoptik.com<br />

14 15

<strong>Jenoptik</strong> sets new standards in industrial metrology.<br />

The Hommel-Etamic W5 is tiny, yet powerful for the<br />

precise testing of surfaces.<br />

Cornelia Ehrler<br />

The Mini for Metrology.<br />

At the 25 th anniversary of CONTROL <strong>2011</strong>, the international<br />

trade fair for quality assurance in Stuttgart, <strong>Jenoptik</strong> surprised<br />

the audience with an innovation that looks small but has much<br />

to offer: The new measuring device HOMMEL-ETAMIC W5<br />

makes mobile testing of surfaces in production even more<br />

comfortable. This roughness measuring is particularly important<br />

in metal processing, for example in the automotive industry and<br />

mechanical engineering, as the surface structure of the work<br />

pieces has to be precise to the micrometer so that their quality<br />

and functionality is guaranteed.<br />

The new mini-device for roughness measurement has it all:<br />

Every technical detail is convincing whether it be practical<br />

relevance, performance or ease of use. Oliver Zanner, Marketing<br />

representative of the Industrial Metrology division, sums up the<br />

benefits simply and briefly: ”The HOMMEL-ETAMIC W5 is powerful,<br />

reliable and versatile.”<br />

Compact and powerful.<br />

The W5 measuring device is, obviously, particularly small and<br />

compact, a little larger than a glasses case and very light. It<br />

weighs only 270 grams, a few grams more than a piece of<br />

butter. Compared to its predecessor, the HOMMEL-ETAMIC<br />

T500, the W5 may be a bit more angular, but above all, it is<br />

state of the art. After two and a half years of development at<br />

the Villingen-Schwenningen location, the new measuring device<br />

HOMMEL-ETAMIC W5 is now in series production.<br />

Because of its size and design, typically in <strong>Jenoptik</strong> blue, the<br />

W5 lies securely in the hand of the tester and can be precisely<br />

and stably positioned on the work piece to be tested. It functions<br />

wirelessly and can therefore easily perform up to 800<br />

roughness measurements, even vertically or upside-down, on a<br />

single charge. In addition, it is also height adjustable: It can be<br />

The new roughness measurement device HOMMEL-ETAMIC W5<br />

is highly efficient and versatile. The measurement results can be<br />

documented on site with the mobile printer.<br />

adjusted to the appropriate work-piece height on its tripod legs.<br />

”Or you can turn the mobile device into a stationary measuring<br />

station with the new height-measuring tripod HS300,” explains<br />

Oliver Zanner.<br />

The specific measurement tasks are fulfilled by the W5 through<br />

the various roughness sensors at the tip of the device, which are<br />

easily replaceable. “The sensors also have long-term stability,”<br />

says Oliver Zanner, ”which means that they do not have to be<br />

readjusted.” The exact measurement results can be read on a<br />

large color display on the top side of the W5. The device functions<br />

are also quickly and easily selected via the color display<br />

and the click wheel.<br />

The high storage capacity allows up to 10,000 measurement<br />

results to be stored directly on the W5. The device operates<br />

with five measurement programs that are compliant with all<br />

international standards for the filtering and evaluation of roughness<br />

parameters. And there are a lot of them: The HOMMEL-<br />

ETAMIC W5 processes 25 roughness parameters, which are<br />

displayed on the color display.<br />

Mobility prioritized.<br />

“There are no limits to the mobility for roughness measurement,”<br />

emphasizes Oliver Zanner, ”as the measurement results<br />

can be documented on site. You either use the mobile printer<br />

HOMMEL-ETAMIC P5 that is controlled via Bluetooth, the wireless<br />

connection technology, and prints parameters, measure-<br />

ment conditions and roughness profiles; or the results can be<br />

transferred to a computer over the measurement device’s USB<br />

interface.”<br />

Precisely these technical properties of the W5 are also the<br />

highlights for Adelbert Leber. “With the HOMMEL-ETAMIC W5<br />

we are ahead of the market,” says the Product manager in Villingen-Schwenningen.<br />

”Bluetooth in this type of mobile measuring<br />

device is otherwise not yet available on the market. The W5 is<br />

also the only one that illuminates the measuring point. And the<br />

size of the device makes it the lightest and most compact in its<br />

class,” says Adelbert Leber not without some pride.<br />

A further development, says Adelbert Leber, is the new platform<br />

concept that the Industrial Metrology division has introduced<br />

with the development of the W5. This has made the integration<br />

of a new generation of electronics and user software possible,<br />

which can now also be used in other products.<br />

After the CONTROL trade fair, Oliver Zanner draws the conclu-<br />

sion. ”Quality assurance is absolutely essential in production,<br />

and our measuring devices – whether mobile or stationary,<br />

small or large – are ideally suited for our customers’ individual<br />

measurement tasks.”<br />

www.jenoptik.com<br />

oliver.zanner@hommel-etamic.com<br />

16<br />

17

Editorial team<br />

In <strong>2011</strong> <strong>Jenoptik</strong> celebrates the company’s 20 th anniversary. According to<br />

plans of the privatization agency “Treuhandanstalt”, <strong>Jenoptik</strong> should not<br />

have existed this long. But, with an entrepreneurial spirit and motivated<br />

employees, the foundation was laid for today’s global optoelectronics Group.<br />

From GDR Collective to<br />

Technology Group.<br />

A big thank you<br />

to all employees<br />

and supporters!<br />

18 19

Twenty years ago, the Group’s future was not looking as bright.<br />

<strong>Jenoptik</strong> was created during the reunification period from the<br />

publicly owned enterprise VEB Carl Zeiss Jena, from which the<br />

“Treuhandanstalt” (Trust agency) initially founded JENOPTIK<br />

Carl Zeiss Jena GmbH. This reflected the <strong>Jenoptik</strong> brand, which<br />

had existed since the fifties and, from 1971, was used for Zeiss<br />

Jena products in the Western states.<br />

Negotiations between the Trust, Carl Zeiss in the East and<br />

West as well as the state governments in Thuringia and Baden-<br />

Württemberg were completed in June 1991 with an agreement<br />

in principle on the restructuring of the Jena parent company<br />

with 13 businesses and about 30,000 employees. Carl Zeiss Jena<br />

GmbH and JENOPTIK GmbH, in which the state of Thuringia<br />

had a 100 percent holding, emerged out of JENOPTIK Carl Zeiss<br />

Jena GmbH. JENOPTIK GmbH assumed the business areas of<br />

optoelectronics, systems engineering and precision manufacturing,<br />

as well as the majority of Zeiss property, as the legal successor<br />

of the Zeiss collective. <strong>Jenoptik</strong> was considered not capable<br />

of being restructured, with around 17,500 Zeiss employees laid<br />

off by the end of 1991 in Jena alone.<br />

According to the trust deed, the former publicly owned com-<br />

pany was to be “liquidated” with 3.6 billion DM. Minus debts,<br />

pensions and subsidies for outsourced businesses, about 600<br />

million DM remained for <strong>Jenoptik</strong>, which was to cover losses<br />

until 1995 by which time <strong>Jenoptik</strong> should really have been a part<br />

of history. But Lothar Späth, as the first Managing Director of<br />

<strong>Jenoptik</strong>, former Premier of the federal county of Baden-Württemberg,<br />

had other plans. He developed, restructured or sold<br />

Zeiss property. <strong>Jenoptik</strong> was able to offset the losses in business<br />

operations and to report a small profit already in 1993. Above<br />

all, it was possible to buy companies with established distribution<br />

networks in the western states. One of the largest acquisitions<br />

was the Meissner + Wurst GmbH in Stuttgart in 1994,<br />

which specialized in clean-room technology for chip factories.<br />

<strong>Jenoptik</strong> has been operating as an Aktiengesellschaft (pub-<br />

lic company) since the start of 1996; from 1997, the state of<br />

Thuringia held 49.99 percent of <strong>Jenoptik</strong>. <strong>Jenoptik</strong> was restructured<br />

in preparation for the IPO in June 1998. After the IPO,<br />

<strong>Jenoptik</strong> increased its focus on the traditional core businesses<br />

of lasers, optics, sensors and mechatronics. As early as 1997,<br />

<strong>Jenoptik</strong> acquired ESW-Extel Systems GmbH, which strengthened<br />

the Photonics and Sensors units and is today the largest<br />

subunit of the Defense & Civil Systems division. ROBOT Foto<br />

and Electronic GmbH, purchased in 1999, is now the Traffic<br />

Solutions division, while Hommelwerke GmbH from Villingen-<br />

Schwenningen, purchased in 2000, represents the Industrial<br />

Metrology division. In 2006, <strong>Jenoptik</strong> separated from M + W<br />

Zander, and thus 85 percent of sales at the time. For the first<br />

time in its existence, <strong>Jenoptik</strong> focused on the traditional hightech<br />

businesses surrounding optoelectronics, which continues<br />

to this day.<br />

This concentration on core competence has been supported<br />

with a new divisional structure since 1997 under the new<br />

leadership of Michael Mertin. With its five divisions of Lasers<br />

& Material Processing, Optical Systems, Industrial Metrology,<br />

Traffic Solutions and Defense & Civil Systems, <strong>Jenoptik</strong> is more<br />

closely oriented to the global markets and its customers, which,<br />

in particular, include companies from the semiconductor and<br />

semiconductor equipment manufacturing industry, automotive<br />

and automotive supplier industry, medical technology, security<br />

and defense technology as well as the aviation industry.<br />

Apart from commercial operations, <strong>Jenoptik</strong> carries responsi-<br />

bility for youth, science and social affairs. <strong>Jenoptik</strong> has been<br />

the third partner in the “Jenaer Bildungszentrum – Schott,<br />

Carl Zeiss, <strong>Jenoptik</strong>” (Jena Educational Center) since 2009, in<br />

which the three companies combine their training in Thuringia.<br />

<strong>Jenoptik</strong> cooperates with the Jena universities in research and<br />

development, among others at the Abbe School of Photonics.<br />

Social responsibility is also reflected in the day care center<br />

“Saaleknirpse”, which had been built on behalf of JENOPTIK <strong>AG</strong><br />

in Jena to give employees a better work/family balance.<br />

In the <strong>2011</strong> anniversary year, <strong>Jenoptik</strong> is ”a financially and<br />

economically sound company,” as Michael Mertin highlights.<br />

The positive development of the Group is continuing in <strong>2011</strong><br />

and has been reflected in its best first quarter in the company’s<br />

recent history. A big thank you to all employees and supporters! www.jenoptik.com<br />

pr@jenoptik.com<br />

20 21

22<br />

JENOPTIK <strong>AG</strong><br />

Carl-Zeiß-Straße 1<br />

D-07739 Jena<br />

www.jenoptik.com<br />

Public Relations<br />

Phone +49(0)3641 65-2255<br />

Fax +49(0)3641 65-2484<br />

pr@jenoptik.com