You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

...AXLE TECH<br />

Axle Tech 101:<br />

What <strong>axle</strong> material do you use? What makes your <strong>axle</strong>s stronger<br />

than stock? Why induction hardening vs thru hardening?<br />

Why are your <strong>axle</strong>s machined after heat treating? These are just<br />

a few of the questions we address every day at Dutchman.<br />

Heat Treat:<br />

Induction hardening is the process<br />

by which an <strong>axle</strong> shaft is<br />

passed thru an electrical coil,<br />

which heats the steel red hot<br />

and then quenches the steel to<br />

make it hard. The amount of<br />

heat put into the steel determines<br />

the case depth-the hotter and<br />

slower the scan, the deeper and<br />

harder the case hardening. The<br />

deeper the case, the stronger<br />

the shaft. Most stock (oem) shafts<br />

are made from 1039 steel, have<br />

a case depth of .125 - .150,<br />

and have a hardness of 50-54<br />

on the Rockwell "C" scale. The<br />

Dutchman 1541-H shafts have<br />

a case depth around the .300<br />

mark and a hardness of 56-59<br />

Rockwell "C" scale. This combo<br />

is what gives a 25-30% strength<br />

increase over stock 1039 shaftsif<br />

you are comparing shafts with<br />

a similar length and spline count.<br />

Thru hardening is a process by<br />

which an <strong>axle</strong> shaft is heated<br />

in a furnace resulting in a shaft<br />

that has the same heat treat<br />

from the center to the outside<br />

diameter. Thru hardened <strong>axle</strong>s<br />

have a hardness of 46-48 on<br />

the Rockwell "C" scale. The hard<br />

case/soft core of an induction<br />

hardened 1541-H shaft yields<br />

its torsional strength & ductility<br />

and the softer "thru Hardening" of<br />

a 4340 shaft yields its torsional<br />

strength & ductility.<br />

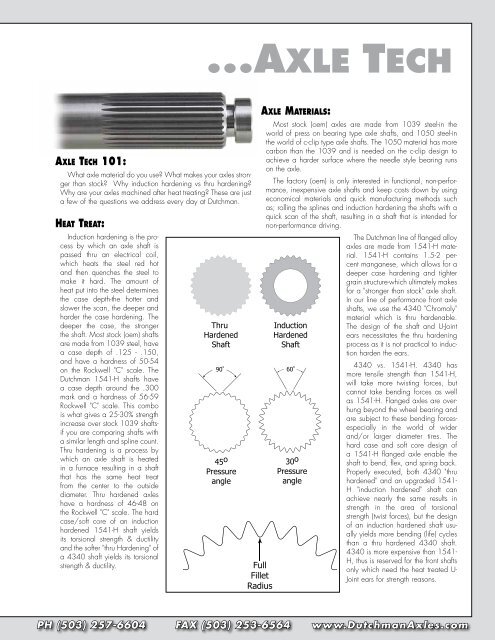

Thru<br />

Hardened<br />

Shaft<br />

Thru<br />

Hardened<br />

Shaft<br />

Thru<br />

Hardened<br />

Shaft<br />

Axle Materials:<br />

Most stock (oem) <strong>axle</strong>s are made from 1039 steel-in the<br />

world of press on bearing type <strong>axle</strong> shafts, and 1050 steel-in<br />

the world of c-clip type <strong>axle</strong> shafts. The 1050 material has more<br />

carbon than the 1039 and is needed on the c-clip design to<br />

achieve a harder surface where the needle style bearing runs<br />

on the <strong>axle</strong>.<br />

The factory (oem) is only interested in functional, non-performance,<br />

inexpensive <strong>axle</strong> shafts and keep costs down by using<br />

economical materials and quick manufacturing methods such<br />

as; rolling the splines and induction hardening the shafts with a<br />

quick scan of the shaft, resulting in a shaft that is intended for<br />

non-performance driving.<br />

Induction<br />

Hardened<br />

Shaft<br />

90 o 60 o<br />

90 o 60 o<br />

Full<br />

Fillet<br />

Radius<br />

Full<br />

Fillet<br />

Radius<br />

Full Fillet<br />

Radius<br />

Fillet<br />

Radius<br />

The Dutchman line of flanged alloy<br />

<strong>axle</strong>s are made from 1541-H material.<br />

1541-H contains 1.5-2 percent<br />

manganese, which allows for a<br />

deeper case hardening and tighter<br />

grain structure-which ultimately makes<br />

for a "stronger than stock" <strong>axle</strong> shaft.<br />

In our line of performance front <strong>axle</strong><br />

shafts, we use the 4340 "Chromoly"<br />

material which is thru hardenable.<br />

The design of the shaft and U-Joint<br />

ears necessitates the thru hardening<br />

process as it is not practical to induction<br />

harden the ears.<br />

4340 vs. 1541-H. 4340 has<br />

more tensile strength than 1541-H,<br />

will take more twisting forces, but<br />

cannot take bending forces as well<br />

as 1541-H. Flanged <strong>axle</strong>s are overhung<br />

beyond the wheel bearing and<br />

are subject to these bending forcesespecially<br />

in the world of wider<br />

and/or larger diameter tires. The<br />

hard case and soft core design of<br />

a 1541-H flanged <strong>axle</strong> enable the<br />

shaft to bend, flex, and spring back.<br />

Properly executed, both 4340 "thru<br />

hardened" and an upgraded 1541-<br />

H "induction hardened" shaft can<br />

achieve nearly the same results in<br />

strength in the area of torsional<br />

strength (twist forces), but the design<br />

of an induction hardened shaft usually<br />

yields more bending (life) cycles<br />

than a thru hardened 4340 shaft.<br />

4340 is more expensive than 1541-<br />

H, thus is reserved for the front shafts<br />

only which need the heat treated U-<br />

Joint ears for strength reasons.<br />

PH (503) 257-6604 FAX (503) 253-6564 www.DutchmanAxles.com<br />

Full<br />

Induction<br />

Hardened<br />

Shaft<br />

Induction<br />

Hardened<br />

Shaft<br />

90 o 60 o<br />

45 o<br />

Pressure<br />

angle<br />

30 o<br />

Pressure<br />

angle