Mixed Matters

ISBN 978-3-86859-421-8

ISBN 978-3-86859-421-8

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

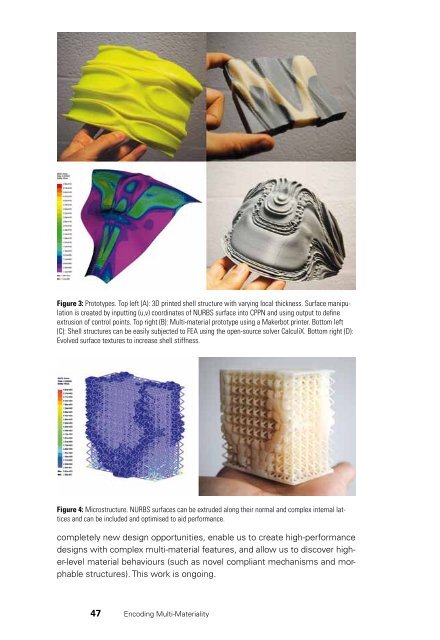

Figure 3: Prototypes. Top left (A): 3D printed shell structure with varying local thickness. Surface manipulation<br />

is created by inputting (u,v) coordinates of NURBS surface into CPPN and using output to define<br />

extrusion of control points. Top right (B): Multi-material prototype using a Makerbot printer. Bottom left<br />

(C): Shell structures can be easily subjected to FEA using the open-source solver CalculiX. Bottom right (D):<br />

Evolved surface textures to increase shell stiffness.<br />

Figure 4: Microstructure. NURBS surfaces can be extruded along their normal and complex internal lattices<br />

and can be included and optimised to aid performance.<br />

completely new design opportunities, enable us to create high-performance<br />

designs with complex multi-material features, and allow us to discover higher-level<br />

material behaviours (such as novel compliant mechanisms and morphable<br />

structures). This work is ongoing.<br />

47 Encoding Multi-Materiality