Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Handling the <strong>Plummer</strong> <strong>Blocks</strong> and Bearings<br />

9.3 Installation of the bearing and associated<br />

components<br />

Once careful checking is complete, install the bearing<br />

and associated components. For the positional<br />

relationship, see Fig. 9.5.<br />

Fig. 9.6<br />

Fig. 9.5<br />

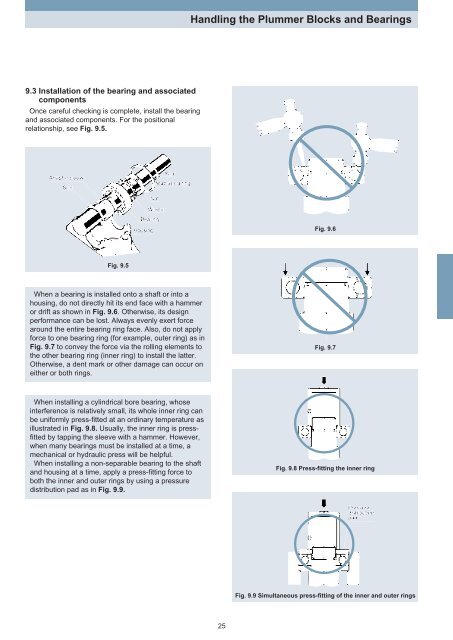

When a bearing is installed onto a shaft or into a<br />

housing, do not directly hit its end face with a hammer<br />

or drift as shown in Fig. 9.6. Otherwise, its design<br />

performance can be lost. Always evenly exert force<br />

around the entire bearing ring face. Also, do not apply<br />

force to one bearing ring (for example, outer ring) as in<br />

Fig. 9.7 to convey the force via the rolling elements to<br />

the other bearing ring (inner ring) to install the latter.<br />

Otherwise, a dent mark or other damage can occur on<br />

either or both rings.<br />

Fig. 9.7<br />

When installing a cylindrical bore bearing, whose<br />

interference is relatively small, its whole inner ring can<br />

be uniformly press-fitted at an ordinary temperature as<br />

illustrated in Fig. 9.8. Usually, the inner ring is pressfitted<br />

by tapping the sleeve with a hammer. However,<br />

when many bearings must be installed at a time, a<br />

mechanical or hydraulic press will be helpful.<br />

When installing a non-separable bearing to the shaft<br />

and housing at a time, apply a press-fitting force to<br />

both the inner and outer rings by using a pressure<br />

distribution pad as in Fig. 9.9.<br />

Fig. 9.8 Press-fitting the inner ring<br />

Fig. 9.9 Simultaneous press-fitting of the inner and outer rings<br />

25