You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Handling the <strong>Plummer</strong> <strong>Blocks</strong> and Bearings<br />

9.3.1 Bearing with an adapter<br />

(1) Thinly apply highly viscous mineral oil to the taper,<br />

threading and the chamfered face of the nut (see<br />

Fig. 9.10) before press-fitting. In particular, apply<br />

molybdenum bisulfide paste to these areas on a<br />

large bearing. This prevents scuffing, and allows<br />

easy bearing removal. Before the installation work,<br />

remove oil from the shaft and the bore face of<br />

sleeve with a clean factory cloth.<br />

the slit with a flat-blade screwdriver for easy fitting.<br />

FIg. 9.11<br />

Fig. 9.11<br />

Fig. 9.10<br />

(2) Mount the adapter to a correct position considering<br />

the dimension B1, B2 or B3 in the bearing table.<br />

When fitting the adapter sleeve onto the shaft, open<br />

(3) Fit the bearing over the adapter sleeve on the shaft<br />

as tight as possible, so that the bearing inner ring is<br />

fully seated onto the taper on adapter sleeve.<br />

(4) Lightly tighten the nut until the sleeve is seated on<br />

the shaft.<br />

(5) When fully tightening a self-aligning ball bearing,<br />

make sure that its radial clearance becomes<br />

approximately 1/2 that before fitting. For a selfaligning<br />

roller bearing, tighten the nut while<br />

measuring its radial clearance with a thickness gage<br />

so that the reduction of radial internal clearance<br />

value in Table 9.1 is reached. Make sure that an<br />

installed self-aligning ball bearing can turn smoothly<br />

by hand (ss Figs. 9.12 and 9.13).<br />

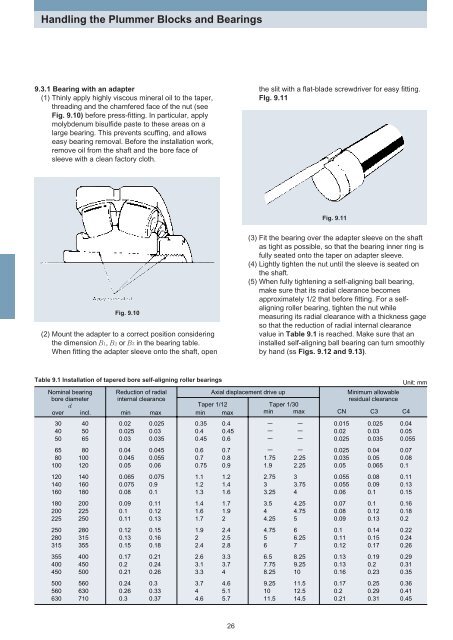

Table 9.1 Installation of tapered bore self-aligning roller bearings<br />

Nominal bearing<br />

bore diameter<br />

d<br />

over incl.<br />

30<br />

40<br />

50<br />

65<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

225<br />

250<br />

280<br />

315<br />

355<br />

400<br />

450<br />

500<br />

560<br />

630<br />

40<br />

50<br />

65<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

225<br />

250<br />

280<br />

315<br />

355<br />

400<br />

450<br />

500<br />

560<br />

630<br />

710<br />

Reduction of radial<br />

internal clearance<br />

Axial displacement drive up<br />

Minimum allowable<br />

residual clearance<br />

Taper 1/12 Taper 1/30<br />

min max min max min max CN C3 C4<br />

0.02<br />

0.025<br />

0.03<br />

0.04<br />

0.045<br />

0.05<br />

0.065<br />

0.075<br />

0.08<br />

0.09<br />

0.1<br />

0.11<br />

0.12<br />

0.13<br />

0.15<br />

0.17<br />

0.2<br />

0.21<br />

0.24<br />

0.26<br />

0.3<br />

0.025<br />

0.03<br />

0.035<br />

0.045<br />

0.055<br />

0.06<br />

0.075<br />

0.9<br />

0.1<br />

0.11<br />

0.12<br />

0.13<br />

0.15<br />

0.16<br />

0.18<br />

0.21<br />

0.24<br />

0.26<br />

0.3<br />

0.33<br />

0.37<br />

0.35<br />

0.4<br />

0.45<br />

0.6<br />

0.7<br />

0.75<br />

1.1<br />

1.2<br />

1.3<br />

1.4<br />

1.6<br />

1.7<br />

1.9<br />

2<br />

2.4<br />

2.6<br />

3.1<br />

3.3<br />

3.7<br />

4<br />

4.6<br />

0.4<br />

0.45<br />

0.6<br />

0.7<br />

0.8<br />

0.9<br />

1.2<br />

1.4<br />

1.6<br />

1.7<br />

1.9<br />

2<br />

2.4<br />

2.5<br />

2.8<br />

3.3<br />

3.7<br />

4<br />

4.6<br />

5.1<br />

5.7<br />

<br />

<br />

<br />

<br />

1.75<br />

1.9<br />

2.75<br />

3<br />

3.25<br />

3.5<br />

4<br />

4.25<br />

4.75<br />

5<br />

6<br />

6.5<br />

7.75<br />

8.25<br />

9.25<br />

10<br />

11.5<br />

<br />

<br />

<br />

<br />

2.25<br />

2.25<br />

3<br />

3.75<br />

4<br />

4.25<br />

4.75<br />

5<br />

6<br />

6.25<br />

7<br />

8.25<br />

9.25<br />

10<br />

11.5<br />

12.5<br />

14.5<br />

0.015<br />

0.02<br />

0.025<br />

0.025<br />

0.035<br />

0.05<br />

0.055<br />

0.055<br />

0.06<br />

0.07<br />

0.08<br />

0.09<br />

0.1<br />

0.11<br />

0.12<br />

0.13<br />

0.13<br />

0.16<br />

0.17<br />

0.2<br />

0.21<br />

0.025<br />

0.03<br />

0.035<br />

0.04<br />

0.05<br />

0.065<br />

0.08<br />

0.09<br />

0.1<br />

0.1<br />

0.12<br />

0.13<br />

0.14<br />

0.15<br />

0.17<br />

0.19<br />

0.2<br />

0.23<br />

0.25<br />

0.29<br />

0.31<br />

Unit: mm<br />

0.04<br />

0.05<br />

0.055<br />

0.07<br />

0.08<br />

0.1<br />

0.11<br />

0.13<br />

0.15<br />

0.16<br />

0.18<br />

0.2<br />

0.22<br />

0.24<br />

0.26<br />

0.29<br />

0.31<br />

0.35<br />

0.36<br />

0.41<br />

0.45<br />

26