Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Handling the <strong>Plummer</strong> <strong>Blocks</strong> and Bearings<br />

(7) If it is difficult to tighten a large bearing by manual<br />

force, use a hydraulic nut or ram for easier<br />

assembly. (See Fig. 9.15.)<br />

Fig. 9.12<br />

Fig. 9.15<br />

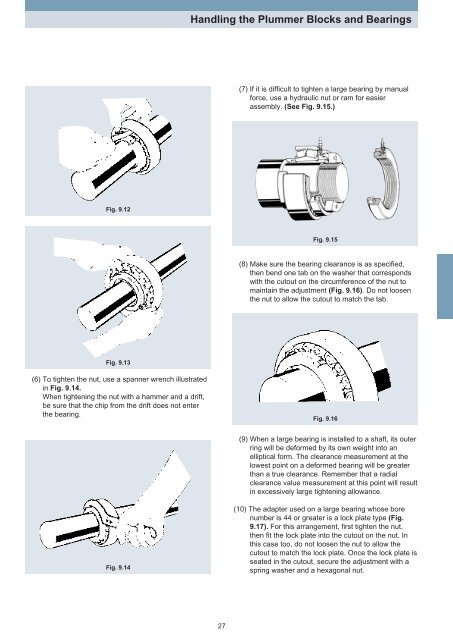

(8) Make sure the bearing clearance is as specified,<br />

then bend one tab on the washer that corresponds<br />

with the cutout on the circumference of the nut to<br />

maintain the adjustment (Fig. 9.16). Do not loosen<br />

the nut to allow the cutout to match the tab.<br />

Fig. 9.13<br />

(6) To tighten the nut, use a spanner wrench illustrated<br />

in Fig. 9.14.<br />

When tightening the nut with a hammer and a drift,<br />

be sure that the chip from the drift does not enter<br />

the bearing.<br />

Fig. 9.16<br />

(9) When a large bearing is installed to a shaft, its outer<br />

ring will be deformed by its own weight into an<br />

elliptical form. The clearance measurement at the<br />

lowest point on a deformed bearing will be greater<br />

than a true clearance. Remember that a radial<br />

clearance value measurement at this point will result<br />

in excessively large tightening allowance.<br />

Fig. 9.14<br />

(10) The adapter used on a large bearing whose bore<br />

number is 44 or greater is a lock plate type (Fig.<br />

9.17). For this arrangement, first tighten the nut,<br />

then fit the lock plate into the cutout on the nut. In<br />

this case too, do not loosen the nut to allow the<br />

cutout to match the lock plate. Once the lock plate is<br />

seated in the cutout, secure the adjustment with a<br />

spring washer and a hexagonal nut.<br />

27