SKF - Spherical Plain Bearings and Rod Ends

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Bearings</strong> <strong>and</strong> rod ends<br />

requiring maintenance<br />

<strong>Bearings</strong> <strong>and</strong> rod ends requiring maintenance<br />

must be greased prior to being put into operation.<br />

With the exception of a few applications,<br />

they must be relubricated periodically.<br />

<strong>SKF</strong> steel/steel radial spherical plain bearings<br />

are made of bearing steel <strong>and</strong> are through-hardened.<br />

The high-strength sliding contact surfaces<br />

are phosphated <strong>and</strong> treated with a special running-in<br />

lubricant. These bearings are used<br />

primarily in applications where there are:<br />

• heavy static loads<br />

• heavy alternating loads<br />

• shock loads<br />

They are also relatively insensitive to contaminants<br />

<strong>and</strong> high temperatures.<br />

To facilitate relubrication, lubrication holes<br />

<strong>and</strong> grooves are provided in both the inner <strong>and</strong><br />

outer rings of all steel/steel radial spherical plain<br />

bearings – with the exception of a few small sizes.<br />

<strong>SKF</strong> steel/bronze rod ends also require relubrication.<br />

However, requirements are less stringent<br />

than for steel/steel rod ends, as the emergency<br />

running properties of bronze are more forgiving<br />

than steel.<br />

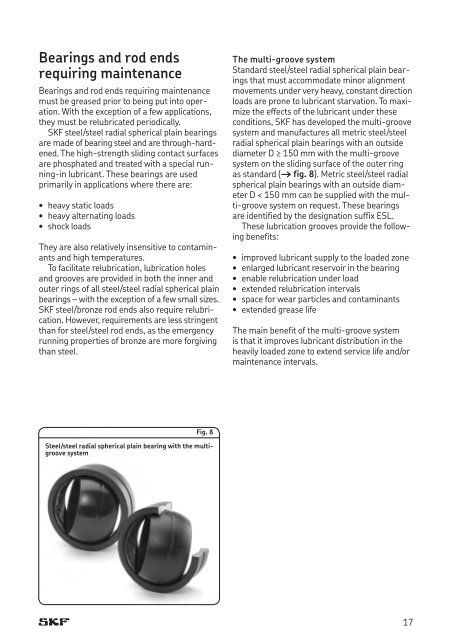

The multi-groove system<br />

St<strong>and</strong>ard steel/steel radial spherical plain bearings<br />

that must accommodate minor alignment<br />

movements under very heavy, constant direction<br />

loads are prone to lubricant starvation. To maximize<br />

the effects of the lubricant under these<br />

conditions, <strong>SKF</strong> has developed the multi-groove<br />

system <strong>and</strong> manufactures all metric steel/steel<br />

radial spherical plain bearings with an outside<br />

dia meter D ≥ 150 mm with the multi-groove<br />

system on the sliding surface of the outer ring<br />

as st<strong>and</strong>ard († fig. 8). Metric steel/steel radial<br />

spherical plain bearings with an outside diameter<br />

D < 150 mm can be supplied with the multi-groove<br />

system on request. These bearings<br />

are identified by the designation suffix ESL.<br />

These lubrication grooves provide the following<br />

benefits:<br />

• improved lubricant supply to the loaded zone<br />

• enlarged lubricant reservoir in the bearing<br />

• enable relubrication under load<br />

• extended relubrication intervals<br />

• space for wear particles <strong>and</strong> contaminants<br />

• extended grease life<br />

The main benefit of the multi-groove system<br />

is that it improves lubricant distribution in the<br />

heavily loaded zone to extend service life <strong>and</strong>/or<br />

maintenance intervals.<br />

Fig. 8<br />

Steel/steel radial spherical plain bearing with the multigroove<br />

system<br />

17