Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

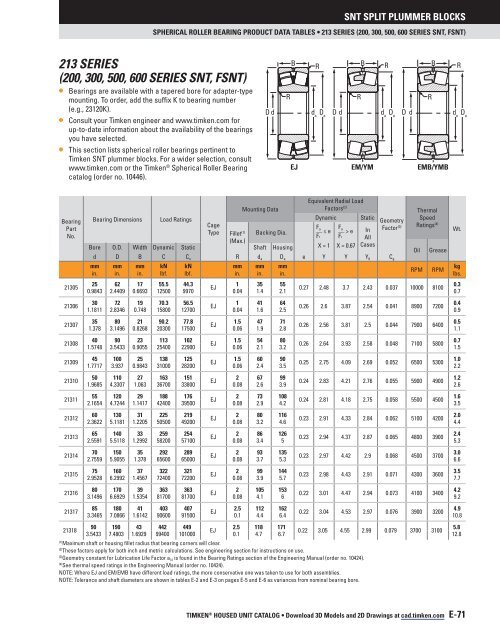

<strong>SNT</strong> SPLIT PLUMMER BLOCKS<br />

SPHERICAL ROLLER BEARING PRODUCT DATA TABLES • 213 SERIES (200, 300, 500, 600 SERIES <strong>SNT</strong>, F<strong>SNT</strong>)<br />

213 Series B<br />

R<br />

B<br />

(200, 300, 500, 600 SERies <strong>SNT</strong>, F<strong>SNT</strong>)<br />

• Bearings are available with a tapered bore for adapter-type<br />

mounting. To order, add<br />

R<br />

the suffix K to bearing number<br />

R R<br />

(e.g., 23120K). D d<br />

D d D d<br />

d a<br />

D a<br />

• Consult your <strong>Timken</strong> engineer and www.timken.com for<br />

up-to-date information about the availability of the bearings<br />

you have selected.<br />

• This section lists spherical roller bearings pertinent to<br />

<strong>Timken</strong> <strong>SNT</strong> plummer blocks. For a wider selection, consult<br />

www.timken.com or the <strong>Timken</strong> ® Spherical Roller Bearing<br />

catalog (order no. 10446). EJ<br />

EJEM/YM<br />

B<br />

R<br />

R<br />

R<br />

dD a<br />

Dd<br />

a<br />

d a<br />

D a<br />

B<br />

EJ<br />

EJ<br />

R<br />

d a<br />

D a<br />

D d<br />

B<br />

R<br />

EM/YM<br />

EM/YM<br />

R<br />

dD a<br />

dD a<br />

B<br />

R<br />

D d<br />

BR<br />

R<br />

d a<br />

D a<br />

EMB/YMB<br />

EM/YMEMB/YMB<br />

R<br />

d a<br />

D a<br />

Bearing<br />

Part<br />

No.<br />

21305<br />

21306<br />

21307<br />

21308<br />

21309<br />

21310<br />

21311<br />

21312<br />

21313<br />

21314<br />

21315<br />

21316<br />

21317<br />

Equivalent Radial Load<br />

Factors (2)<br />

Dynamic Static<br />

Mounting Data<br />

Bearing Dimensions Load Ratings<br />

Cage<br />

Type Fillet (1) Backing Dia.<br />

__ F a F ≤ e __ a > e In<br />

Fr Fr All<br />

(Max.)<br />

Bore O.D. Width Dynamic Static Shaft Housing X = 1 X = 0.67 Cases<br />

d D B C C o R d a D a e Y Y Y 0 C g<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

kN<br />

lbf.<br />

kN<br />

lbf.<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

Geometry<br />

Factor (3)<br />

Thermal<br />

Speed<br />

Ratings (4)<br />

Oil<br />

Grease<br />

Wt.<br />

RPM RPM kg<br />

lbs.<br />

0.3<br />

0.27 2.48 3.7 2.43 0.037 10000 8100<br />

25 62 17 55.5 44.3<br />

1 35 55<br />

EJ<br />

0.9843 2.4409 0.6693 12500 9970 0.04 1.4 2.1 0.7<br />

30 72 19 70.3 56.5<br />

1 41 64<br />

0.4<br />

EJ<br />

0.26 2.6 3.87 2.54 0.041 8900 7200<br />

1.1811 2.8346 0.748 15800 12700 0.04 1.6 2.5 0.9<br />

35 80 21 90.2 77.8<br />

1.5 47 71<br />

0.5<br />

EJ<br />

0.26 2.56 3.81 2.5 0.044 7900 6400<br />

1.378 3.1496 0.8268 20300 17500 0.06 1.9 2.8 1.1<br />

40 90 23 113 102<br />

1.5 54 80<br />

0.7<br />

EJ<br />

0.26 2.64 3.93 2.58 0.048 7100 5800<br />

1.5748 3.5433 0.9055 25400 22900 0.06 2.1 3.2 1.5<br />

45 100 25 138 125<br />

1.5 60 90<br />

1.0<br />

EJ<br />

0.25 2.75 4.09 2.69 0.052 6500 5300<br />

1.7717 3.937 0.9843 31000 28200 0.06 2.4 3.5 2.2<br />

50 110 27 163 151<br />

2 67 99<br />

1.2<br />

EJ<br />

0.24 2.83 4.21 2.76 0.055 5900 4900<br />

1.9685 4.3307 1.063 36700 33800 0.08 2.6 3.9 2.6<br />

55 120 29 188 176<br />

2 73 108<br />

1.6<br />

EJ<br />

0.24 2.81 4.18 2.75 0.058 5500 4500<br />

2.1654 4.7244 1.1417 42400 39500 0.08 2.9 4.2 3.5<br />

60 130 31 225 219<br />

2 80 116<br />

2.0<br />

EJ<br />

0.23 2.91 4.33 2.84 0.062 5100 4200<br />

2.3622 5.1181 1.2205 50500 49200 0.08 3.2 4.6 4.4<br />

65 140 33 259 254<br />

2 86 126<br />

2.4<br />

EJ<br />

0.23 2.94 4.37 2.87 0.065 4800 3900<br />

2.5591 5.5118 1.2992 58200 57100 0.08 3.4 5 5.3<br />

70 150 35 292 289<br />

2 93 135<br />

3.0<br />

EJ<br />

0.23 2.97 4.42 2.9 0.068 4500 3700<br />

2.7559 5.9055 1.378 65600 65000 0.08 3.7 5.3 6.6<br />

75 160 37 322 321<br />

2 99 144<br />

3.5<br />

EJ<br />

0.23 2.98 4.43 2.91 0.071 4300 3600<br />

2.9528 6.2992 1.4567 72400 72200 0.08 3.9 5.7 7.7<br />

80 170 39 363 363<br />

2 105 153<br />

4.2<br />

EJ<br />

0.22 3.01 4.47 2.94 0.073 4100 3400<br />

3.1496 6.6929 1.5354 81700 81700 0.08 4.1 6 9.2<br />

85 180 41 403 407<br />

2.5 112 162<br />

4.9<br />

EJ<br />

0.22 3.04 4.53 2.97 0.076 3900 3200<br />

3.3465 7.0866 1.6142 90600 91500 0.1 4.4 6.4 10.8<br />

90 190 43 442 449<br />

2.5 118 171<br />

5.8<br />

21318<br />

EJ<br />

0.22 3.05 4.55 2.99 0.079 3700 3100<br />

3.5433 7.4803 1.6929 99400 101000 0.1 4.7 6.7 12.8<br />

(1)<br />

Maximum shaft or housing fillet radius that bearing corners will clear.<br />

(2)<br />

These factors apply for both inch and metric calculations. See engineering section for instructions on use.<br />

(3)<br />

Geometry constant for Lubrication Life Factor a 31 is found in the Bearing Ratings section of the Engineering Manual (order no. 10424).<br />

(4)<br />

See thermal speed ratings in the Engineering Manual (order no. 10424).<br />

Note: Where EJ and EM/EMB have different load ratings, the more conservative one was taken to use for both assemblies.<br />

NOTE: Tolerance and shaft diameters are shown in tables E-2 and E-3 on pages E-5 and E-6 as variances from nominal bearing bore.<br />

TIMKEN ® HOUSED UNIT CataloG • Download 3D Models and 2D Drawings at cad.timken.com E-71