SPLIT SYSTEM AIR CONDITIONER TECHNICAL & SERVICE ...

SPLIT SYSTEM AIR CONDITIONER TECHNICAL & SERVICE ...

SPLIT SYSTEM AIR CONDITIONER TECHNICAL & SERVICE ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TECHNICAL</strong> & <strong>SERVICE</strong> MANUAL<br />

ADR518CW AE518SC<br />

AE518SC3 / AER518SCL3<br />

ADR518HW AE518SH<br />

AE518SH3 / AER518SH3<br />

INDOOR UNIT<br />

<strong>SPLIT</strong> <strong>SYSTEM</strong> <strong>AIR</strong> <strong>CONDITIONER</strong><br />

0.8180.224.0<br />

OUTDOOR UNIT<br />

®<br />

OCTOBER 01

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

L<br />

M<br />

N<br />

O<br />

P<br />

Q<br />

R<br />

H<br />

TABLE OF CONTENTS<br />

SPECIFICATIONS...........................................................................................................PAGE...3<br />

MAJOR COMPONENT SPECIFICATION.....................................................................................9<br />

OTHERS COMPONENT SPECIFICATIONS................................................................................16<br />

OPERATING RANGE....................................................................................................................21<br />

DIMENSIONALE DATA.................................................................................................................22<br />

FUNCTION.....................................................................................................................................24<br />

REFRIGERANT FLOW DIAGRAM................................................................................................31<br />

ELECTRIC WIRING DIAGRAM.....................................................................................................32<br />

TROUBLESHOOTING COOLING MODEL...................................................................................36<br />

SAME PARTS OF <strong>AIR</strong> <strong>CONDITIONER</strong> DO NOT OPERATE........................................................43<br />

<strong>AIR</strong> <strong>CONDITIONER</strong> OPERATES,BUT ABNORMALITIES OCCUR.............................................44<br />

TROUBLESHOOTING HEATING MODEL....................................................................................45<br />

SAME PARTS OF <strong>AIR</strong> <strong>CONDITIONER</strong> DO NOT OPERATE.......................................................52<br />

<strong>AIR</strong> <strong>CONDITIONER</strong> OPERATES,BUT ABNORMALITIES OCCUR............................................55<br />

IS SENSOR IS DEFECTIVE..........................................................................................................56<br />

CHECKING ELECTRICAL ...........................................................................................................59

A SPECIFICATIONS<br />

1)UNIT SPECIFICATIONS<br />

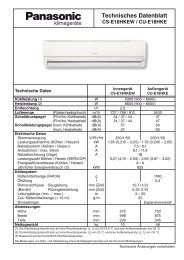

UNIT MODEL<br />

Power source 220 / 230 / 240V - 1 - 50 Hz<br />

Shipping volume m 3 0,33 0,3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 4.950 (4,250)<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

3<br />

ADR518CW<br />

AE518SC<br />

PERFORMANCES COOLING<br />

Capacity<br />

BTU/h 16,900<br />

Air circulation (high - med - low) m 3 /h 780<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49) at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2,8<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 230<br />

Available voltage range V 198 ÷ 264<br />

Running ampere A 9.5<br />

Power input W 2,06<br />

Power factor % 94<br />

Compressor locked rotor amperes A 46<br />

C.O.P.<br />

FEATURES<br />

W/W 2.4<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R22 / capillary tube / 1.710 g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51 / 44<br />

Max. tubing length m (with factory R22 charge) 10<br />

Max. allowable tubing length m ....(with.R22.addition)....................20<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

m<br />

between the two units 7<br />

Refrigerant tube<br />

diameter<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6.35 (1/4”)<br />

12.7 (1/2”)<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

Data subject to change without notice.

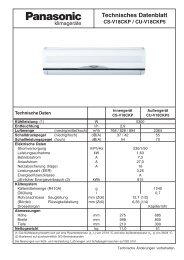

UNIT MODEL<br />

Power source 400V - 3N - 50 Hz (4 wires)<br />

Shipping volume m 3 0,33 0,3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 4.950 (4250)<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

4<br />

ADR518CW<br />

AE518SC3<br />

PERFORMANCES COOLING<br />

Capacity<br />

BTU/h 16,900<br />

Air circulation (high - med - low) m 3 /h 780<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49) at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2,8<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 400<br />

Available voltage range V 342 ÷ 440<br />

Running ampere A 4.0<br />

Power input W 1.96<br />

Power factor % 84<br />

Compressor locked rotor amperes A 21.5<br />

C.O.P.<br />

FEATURES<br />

W/W 2.5<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R22 / capillary tube / 1.405 g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51 / 44<br />

Max. tubing length m (with factory R22 charge) 10<br />

Max. allowable tubing length m ....(with.R22.addition).....................20<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

between the two units<br />

Refrigerant tube<br />

diameter<br />

m<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6,35 (1/4”)<br />

12,7 (1/2”)<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

7<br />

Data subject to change without notice.

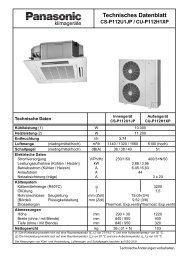

UNIT MODEL<br />

Power source 400V - 3N - 50 Hz (4 wires)<br />

Shipping volume m 3 0.33 0.3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 5900 (5070)<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

5<br />

ADR518CW<br />

AER518SCL3<br />

PERFORMANCES COOLING<br />

Capacity<br />

BTU/h 17.400<br />

Air circulation (high - med - low) m 3 /h 780<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49 at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2.8<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 400<br />

Available voltage range V 342 : 440<br />

Running ampere A 3.6<br />

Power input W 2.000<br />

Power factor % 80<br />

Compressor locked rotor amperes A 21.5<br />

C.O.P.<br />

FEATURES<br />

W/W 2,3<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R407C / capillary tube / 1.710 g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51/ 44<br />

Max. tubing length m (with factory R407C charge) 10<br />

Max. allowable tubing length m (with R407C addition) 30<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

between the two units<br />

Refrigerant tube<br />

diameter<br />

m<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6,35 (1/4”)<br />

12.7(1/2")<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

7<br />

Data subject to change without notice.

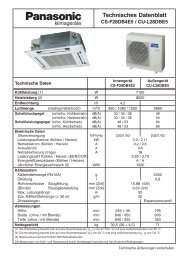

UNIT MODEL<br />

Power source 220 / 230 / 240V - 1 - 50 Hz<br />

Shipping volume m 3 0,33 0.3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 4.950 (4.257) 6000(5160)<br />

6<br />

ADR518HW<br />

AE518SH<br />

PERFORMANCES COOLING HEATING<br />

Capacity<br />

BTU/h 16.900 20500<br />

Air circulation (high - med - low) m 3 /h 750<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49) at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2.8 ---<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 230<br />

Available voltage range V 198 ÷ 264<br />

Running ampere A 9.8 10.3<br />

Power input W 2.100 2.150<br />

Power factor % 93 90<br />

Compressor locked rotor amperes A 57<br />

C.O.P. W/W 2.35 2.8<br />

FEATURES<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R22 / capillary tube / 1.87 g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51 / 44<br />

Max. tubing length m (standard refrigerant charge) 10<br />

Max. allowable tubing length m ....(with.R22.addition).....................30<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

between the two units<br />

Refrigerant tube<br />

diameter<br />

m<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6,35 (1/4”)<br />

12.7 (1/2”)<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

Data subject to change without notice.<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

7

UNIT MODEL<br />

Power source 400V - 3N - 50 Hz (4 wires)<br />

Shipping volume m 3 0,33 0.3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 4.700 (4.042) 5.800(6.744)<br />

7<br />

ADR518HW<br />

AE518SH3<br />

PERFORMANCES COOLING HEATING<br />

Capacity<br />

BTU/h 16.100 19.800<br />

Air circulation (high - med - low) m 3 /h 750<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49) at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2.8 ---<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 400<br />

Available voltage range V 342 ÷ 440<br />

Running ampere A 3.8 4.0<br />

Power input W 2.000 2.100<br />

Power factor % 93 90<br />

Compressor locked rotor amperes A 22<br />

C.O.P. W/W 2.35 2.76<br />

FEATURES<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R22 / capillary tube / 2.450g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51 / 44<br />

Max. tubing length m (standard refrigerant charge) 10<br />

Max. allowable tubing length m ....(with.R22.addition).....................30<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

between the two units<br />

Refrigerant tube<br />

diameter<br />

m<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6,35 (1/4”)<br />

12.7 (1/2”)<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

Data subject to change without notice.<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

7

UNIT MODEL<br />

Power source 400V - 3N - 50 Hz (4 wires)<br />

Shipping volume m 3 0,33 0.3<br />

Shipping weight (approx.) kg 44 57<br />

NOTA. Rating conditions:<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

W (Kcal/h) 4.800 (4.128) 6300(5418)<br />

8<br />

ADR518HW<br />

AER518SH3<br />

PERFORMANCES COOLING HEATING<br />

Capacity<br />

BTU/h 16.400 21.500<br />

Air circulation (high - med - low) m 3 /h 750<br />

External static pressure (high speed) mm w.g. (Pa) 5 (49) at shipment - 10 (98) using the Booster cable<br />

Moisture removal (high speed) l/h 2.8 ---<br />

Umidità ELECTRICAL asportata RATINGS (alta velocità) l/h 0,9<br />

Voltage rating V 400<br />

Available voltage range V 342 ÷ 440<br />

Running ampere A 4.0 4.2<br />

Power input W 2.150 2.250<br />

Power factor % 93 90<br />

Compressor locked rotor amperes A 22<br />

C.O.P. W/W 2.23 2.8<br />

FEATURES<br />

Controls Microprocessor<br />

Control unit Remote control<br />

Temperature control I.C. thermostat<br />

Timer ON/OFF 12 hours<br />

Fan speed indoor / outdoor 3 + auto / 2 auto<br />

Air filter Washable, easy access (accessory)<br />

Compressor Rotary (hermetic)<br />

Refrigerant / ref. control / amount charged at ship g R407C / capillary tube / 1.600 g<br />

Operation sound<br />

Indoor Hi / Me / Lo (1 m) dB-A<br />

Outdoor Hi / Lo (3 m) dB-A<br />

42 / 37 / 32<br />

51 / 44<br />

Max. tubing length m (standard refrigerant charge) 10<br />

Max. allowable tubing length m ....(with.R407C.addition)................30<br />

Required amount of additional refrigerant g/m 25<br />

Limit of elevation difference<br />

between the two units<br />

Refrigerant tube<br />

diameter<br />

m<br />

Narrow tube mm (in.)<br />

Wide tube mm (in.)<br />

6,35 (1/4”)<br />

12.7 (1/2”)<br />

Accessory Booster cable<br />

DIMENSIONS AND WEIGTH INDOOR UNIT OUTDOOR UNIT<br />

Higth mm 316 630<br />

Width mm 750 830<br />

Depth mm 665 305<br />

Net weigth kg 42 52<br />

Data subject to change without notice.<br />

Cooling: Outside air temp.: 35°C DB, indoor unit entering air temp.: 27°C DB / 19°C WB<br />

7

B MAJOR COMPONENT SPECIFICATIONS<br />

INDOOR UNIT<br />

UNIT MODEL ADR518CW / ADR518HW<br />

Power source 220 / 230 / 240V -1 - 50 Hz<br />

REMOTE CONTROL UNIT RCS-U251G<br />

CONTROLLER P.C.B. POW-U186GH<br />

Controls Microprocessor<br />

Control circuit fuse 250V - 3A<br />

FAN Centrifugal<br />

Number ... dia. / length mm 2 ... Ø 200 / L 230<br />

FAN MOTOR<br />

Model ... Number K48410M01526 ... 1<br />

Power source V 220 / 230 / 240-1-50 Hz<br />

No. di poli ... giri/min (230V-max) 4 ... 1040<br />

Nominal output W 70<br />

Coil resistance<br />

(Ambient temp. 20°C)<br />

SAFETY DEVICES Internal type<br />

Operating temp.<br />

Open<br />

Close<br />

°C<br />

°C<br />

130 ± 18<br />

179 ± 15<br />

Run capacitor<br />

Rated<br />

µF 5<br />

VAC 440<br />

Voltage AC 230V - 50 Hz<br />

Input 114.7 W<br />

Coil Aluminum plate fin / Copper tube<br />

Fin pitch mm 1,8<br />

Fase area m 2 0,125<br />

EXTERNAL FINISH<br />

Ω WHT - BRN :181,1<br />

9<br />

ORG - VLT :136,8<br />

YEL - ORG :151,4<br />

BLK - YEL :120,6<br />

WHT - VLT :112,7<br />

VLT - PNK :144,2<br />

DRAIN PUMP<br />

Model PC<br />

Total head capacity 0.4 m / 0.6 l/m<br />

HEAT EXCHANGER<br />

Rows 3<br />

Insulated galvanized metal sheet

Outdoor Unit AE518SC3<br />

Controller<br />

PCB<br />

Part No. POW-C181BL<br />

Control circuit fuse 250V – 5A<br />

Type Rotary (Hermetic)<br />

Compressor model C-2R173H8V- 80817C88D<br />

Source 380 – 400 V – 3N ~ 50 Hz<br />

Nominal output W 1,700<br />

Compressor oil ... Amount cc SUNISO 4GSD-T ... 800<br />

Coil resistance (Ambient temp. 25°C) Ω C – R : 6.369<br />

C – S : 6.073<br />

R – S : 6.217<br />

Type Internal protector External protector<br />

Safety<br />

devices<br />

Overload relay<br />

Operating temp.<br />

Open<br />

Close<br />

°C<br />

°C<br />

—<br />

125 ± 5<br />

Automatic reclosing<br />

HOE-10TB TH-5A<br />

—<br />

—<br />

Operating amp.(Ambient temp. 25°C) — 5A<br />

Run capacitor<br />

µF<br />

VAC<br />

—<br />

—<br />

Crank case heater 240V 30W<br />

Type Propeller<br />

Q´ty ... Dia. mm 1 ... ø400<br />

Fan motor model ... Q´ty SMEN 19 TFB6055 ... 1<br />

Source 220 – 230 V ~ 50 Hz<br />

No. of poles ... rpm (220 V, High) 6 ... 910<br />

Nominal output W 43<br />

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 77.7 WHT - YEL : 366<br />

WHT – PNK : 211<br />

Safety<br />

devices<br />

Type<br />

Operating temp.<br />

Open<br />

Close<br />

°C<br />

Internal type<br />

130 ± 5<br />

Automatic reclosing<br />

Run capacitor<br />

µF<br />

VAC<br />

2.0<br />

400<br />

Coil Aluminum plate fin / Copper tube<br />

Rows 2<br />

Fin pitch mm 1.8<br />

Face area m 2<br />

0.508<br />

External Finish Acrylic baked-on enamel finish<br />

Compressor<br />

Fan & Fan Motor<br />

Heat<br />

Exch. Coil<br />

10<br />

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Outdoor Unit AE518SC<br />

Controller PCB —<br />

Compressor<br />

Type Rotary (Hermetic)<br />

Compressor model PH36VTRT<br />

Nominal output W 1,600<br />

Compressor oil ... Amount cc DIAMOND... 900<br />

Coil resistance (Ambient temp. 20°C) Ω C – R : 1.06<br />

11<br />

C – S : 2.03<br />

Type Internal protector (OLR)<br />

Safety Overload relay —<br />

devices Operating temp. Open °C Automatic opening 155 ± 5<br />

Close °C Automatic reclosing 90 ± 10<br />

Operating amp. (Ambient temp. 25 C) Trip in 3 to 10 sec at 54A<br />

Run capacitor µF 55.0<br />

VAC 450<br />

Crank case heater —<br />

Type Propeller<br />

Number ... Dia. mm 1 ... ø 400<br />

Fan motor model ... Number Smen 19TFB6055 ... 1<br />

No. of poles ... rpm (230 V, High) 6 ... 910<br />

Nominal output W 43<br />

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 77.7 ± 7%<br />

WHT – YEL : 366.0 ± 7%<br />

WHT – PNK : 211.0 ± 7%<br />

Safety Type Thermal protector<br />

devices Operating temp. Open °C 130 ± 5<br />

Close Automatic reclosing<br />

Run capacitor µF 2.0<br />

VAC 440<br />

Coil Aluminum plate fin / Copper tube<br />

Rows 2<br />

Fin pitch mm 1.8<br />

Face area m2 0.508<br />

External Finish Acrylic baked-on enamel finish<br />

Fan & Fan Motor<br />

Heat<br />

Exch. Coil<br />

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Outdoor Unit AER518SCL3<br />

Controller<br />

PCB<br />

Part No. POW-C181BL<br />

Control circuit fuse 250V – 5A<br />

Type Rotary (Hermetic)<br />

Compressor model C-2RN173H8W 80807088<br />

Source 380 – 400 V – 3N ~ 50 Hz<br />

Nominal output W 1,700<br />

Compressor oil ... Amount cc FV68S ... 800<br />

Coil resistance (Ambient temp. 25°C) Ω C – R : 6.369<br />

C – S : 6.073<br />

R – S : 6.217<br />

Type Internal protector External protector<br />

Safety<br />

devices<br />

Overload relay<br />

Operating temp.<br />

Open<br />

Close<br />

°C<br />

°C<br />

—<br />

Automatic opening<br />

Automatic reclosing<br />

HOE-10TB TH-5A<br />

—<br />

—<br />

Operating amp.(Ambient temp. 25°C) — 5A<br />

Run capacitor<br />

µF<br />

VAC<br />

—<br />

—<br />

Crank case heater 240V 30W<br />

Type Propeller<br />

Q´ty ... Dia. mm 1 ... ø400<br />

Fan motor model ... Q´ty SMEN 19 TFB6047 ... 1<br />

Source 220 – 230 V ~ 50 Hz<br />

No. of poles ... rpm (220 V, High) 6 ... 910<br />

Nominal output W 43<br />

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 83.4<br />

WHT – PNK : 218.7<br />

Safety<br />

devices<br />

Type<br />

Operating temp.<br />

Open<br />

Close<br />

°C<br />

Internal type<br />

130 ± 5<br />

Automatic reclosing<br />

Run capacitor<br />

µF<br />

VAC<br />

2.0<br />

440<br />

Coil Aluminum plate fin / Copper tube<br />

Rows 2<br />

Fin pitch mm 1.8<br />

Face area m 2<br />

0.508<br />

External Finish Acrylic baked-on enamel finish<br />

Compressor<br />

Fan & Fan Motor<br />

Heat<br />

Exch. Coil<br />

12<br />

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Outdoor Unit AE518SH<br />

Controller PCB POW–C186GH<br />

Compressor<br />

Type Rotary (Hermetic)<br />

Compressor model SCI PH36VTRT<br />

Nominal output W 1600<br />

Compressor oil ... Amount cc DIAMOND....900<br />

Coil resistance (Ambient temp. 20°C) Ω C – R : 1.06<br />

13<br />

C – S : 2.03<br />

Type Internal protector External (OLR)<br />

Safety Overload relay MRA-8967-9200<br />

devices Operating temp. Open °C 160 ± 5<br />

Close °C 84± 11<br />

Operating amp.(Ambient temp. 25°C) Trip in 6 to 16 sec. at 55 A<br />

Run capacitor µF 55.0<br />

VAC 450<br />

Crank case heater 240V 30W<br />

Type Propeller<br />

Number ... Dia. mm 1 ... ø 400<br />

Fan motor model ... Number Smen 19TFB6055 ... 1<br />

No. of poles ... rpm (230 V, High) 6 ... 900<br />

Nominal output W 50<br />

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 77.7 ± 7%<br />

WHT – YEL : 366.0 ± 7%<br />

WHT – PNK : 211 ± 7%<br />

Safety Type Internal protector<br />

devices Operating temp. Open °C 130 ±8<br />

Close Automatic reclosing<br />

Run capacitor µF 2.0<br />

VAC 440<br />

Coil Aluminum plate fin / Copper tube<br />

Rows 2<br />

Fin pitch mm 1.6<br />

Face area m2 0.453<br />

External Finish Acrylic baked-on enamel finish<br />

Fan & Fan Motor<br />

Heat<br />

Exch. Coil<br />

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Outdoor Unit AE518SH3<br />

Power source<br />

Control circuit<br />

CONTROLLER PCB<br />

COMPRESSOR<br />

Type<br />

Compressor model<br />

Source<br />

Nominal output W<br />

Compressor oil ... Amount cc<br />

Coil resistance (Ambient temp. 25°C)<br />

C - R Ω<br />

C - S Ω<br />

R - S Ω<br />

380 - 400 V - 3N ~ 50 Hz<br />

220 - 240 V ~ 50 Hz<br />

POW-C186GH<br />

Rotary (Hermetic)<br />

C-R173H8M-806-389-88<br />

380 - 400 V - 3N ~ 50 Hz<br />

1700<br />

SUNISO4CS ... 800<br />

5,62<br />

5,51<br />

5,62<br />

Safety devices: Type Internal protector External protector<br />

Overload relay // HOE-10TB TH-7A<br />

Operating temp.<br />

Open °C 120 ± 5 //<br />

Close °C Automatic reclosing //<br />

Operating amp. (Ambient temp. 25°C) // 5 A<br />

µF<br />

VAC<br />

Crank case heater<br />

FAN AND FAN MOTOR<br />

Type<br />

Number ... Dia. mm<br />

Fan motor model ... Number<br />

Source<br />

No. of poles ... rpm (220 V)<br />

Nominal output W<br />

WHT - BRN Ω<br />

WHT - YEL Ω<br />

Safety devices: Type<br />

Open<br />

Close<br />

°C<br />

HEAT EXCH. COIL<br />

µF<br />

VAC<br />

Coil<br />

Rows<br />

Fin pitch mm<br />

Face area m 2<br />

Run capacitor<br />

//<br />

//<br />

240 V - 30 W<br />

Propeller<br />

1 ... Ø400<br />

Smen 19TFB6055 ... 1<br />

220 - 240 V ~ 50 Hz<br />

6 ... 900<br />

50<br />

77,7<br />

Coil resistance (Ambient temp. 20°C)<br />

366,0<br />

WHT - PNK Ω<br />

211,0<br />

Internal protector<br />

Operating temp.<br />

130 ± 8<br />

Automatic reclosing<br />

Run capacitor<br />

2<br />

440<br />

Aluminum plate fin / Copper tube<br />

2<br />

1,6<br />

0,453<br />

EXTERNAL FINISH<br />

Acrylic baked-on enamel finish<br />

14<br />

Data subject to change without notice.

Outdoor Unit AER518SH3<br />

Power source<br />

Control circuit<br />

CONTROLLER PCB<br />

COMPRESSOR<br />

Type<br />

Compressor model<br />

Source<br />

Nominal output W<br />

Compressor oil ... Amount cc<br />

Coil resistance (Ambient temp. 25°C)<br />

C - R Ω<br />

C - S Ω<br />

R - S Ω<br />

380 - 400 V - 3N ~ 50 Hz<br />

220 - 240 V ~ 50 Hz<br />

POW-C186GH<br />

Rotary (Hermetic)<br />

C-2RN173H8A 80242088<br />

380 - 400 V - 3N ~ 50 Hz<br />

1700<br />

FV68S ... 800<br />

5,62<br />

5,51<br />

5,62<br />

Safety devices: Type Internal protector External protector<br />

Overload relay // HOE-10TB TH-7A<br />

Operating temp.<br />

Open °C 120 ± 5 //<br />

Close °C Automatic reclosing //<br />

Operating amp. (Ambient temp. 25°C) // 5 A<br />

µF<br />

VAC<br />

Crank case heater<br />

FAN AND FAN MOTOR<br />

Type<br />

Number ... Dia. mm<br />

Fan motor model ... Number<br />

Source<br />

No. of poles ... rpm (220 V)<br />

Nominal output W<br />

WHT - BRN Ω<br />

WHT - YEL Ω<br />

Safety devices: Type<br />

Open<br />

Close<br />

°C<br />

HEAT EXCH. COIL<br />

µF<br />

VAC<br />

Coil<br />

Rows<br />

Fin pitch mm<br />

Face area m 2<br />

Run capacitor<br />

//<br />

//<br />

240 V - 30 W<br />

Propeller<br />

1 ... Ø400<br />

Smen 19TFB6055 ... 1<br />

220 - 240 V ~ 50 Hz<br />

6 ... 900<br />

50<br />

77,7<br />

Coil resistance (Ambient temp. 20°C)<br />

366,0<br />

WHT - PNK Ω<br />

211,0<br />

Internal protector<br />

Operating temp.<br />

130 ± 8<br />

Automatic reclosing<br />

Run capacitor<br />

2<br />

440<br />

Aluminum plate fin / Copper tube<br />

2<br />

1,6<br />

0,453<br />

EXTERNAL FINISH<br />

Acrylic baked-on enamel finish<br />

15<br />

Data subject to change without notice.

C OTHER COMPONENT SPECIFICATIONS<br />

Outdoor Unit AE518SC<br />

Power Relay G7L-2A-TUB<br />

Coil rating AC 200–240V, 50/60Hz<br />

Coil resistance kΩ (at 23°C) ( 21 ± 15% )<br />

Contact rating AC 220V, 25A<br />

Thermostat (Fan Speed Control 23S) MQT5S-27YZJ<br />

Switching temp. °C high ➞ LOW 23.5°C +0<br />

–2.5<br />

low ➞ HIGH 27.0°C +0<br />

–3<br />

Contact rating AC 220V, 3A<br />

Outdoor Unit AE518SC3<br />

Negative Phase Relay (47C) RDR-S400<br />

Rating AC 415V, 3-phase 50Hz<br />

Contact rating AC 400V, 1A<br />

Operation Positive phase: ON<br />

16<br />

Negative phase: OFF<br />

Electro Magnetic Contactor (MG) HOE-10TB TH-5A<br />

Magnetic contactor<br />

Coil rating AC 220–240V, 50Hz / AC 240–260V, 60Hz<br />

Coil resistance Ω (at 25°C) 1,260 ± 10%<br />

Contact rating (Main) AC 440V, 8A<br />

Thermal relay (Overcurrent relay)<br />

MQT5S-27YZJ<br />

Operating amperes 5A

Outdoor Unit AER518SCL3<br />

Thermistor (Coil sensor TH3 / Air sensor TH4) PBC-41E-S4 / PBC-41E-S8<br />

Resistance kΩ –20°C 40.1 ± 5% 20°C 6.5 ± 5%<br />

Solid State Relay (SSR) G3L-205TL-TS1<br />

Input<br />

Rated voltage DC 12V<br />

Control voltage range DC 0V to 6.4V<br />

Load voltage range AC 75V to 264V, 50Hz<br />

Negative Phase Relay (47C) RDR-S400<br />

Rating AC 415V, 3-phase 50Hz<br />

Contact rating AC 400V, 1A<br />

Operation Positive phase: ON<br />

Negative phase: OFF<br />

Electro Magnetic Contactor (MG) HOE-10TB TH-5A<br />

Magnetic contactor<br />

Coil rating AC 220–240V, 50Hz / AC 240–260V, 60Hz<br />

Coil resistance Ω (at 25°C) 1,260 ± 10%<br />

Contact rating (Main) AC 440V, 8A<br />

Thermal relay (Overcurrent relay)<br />

–10°C 24.4 ± 5% 30°C 4.4 ± 5%<br />

Operating amperes 5A<br />

0°C 15.3 ± 5% 40°C 3.0 ± 5%<br />

10°C 9.9 ± 5% 50°C 2.1 ± 5%<br />

Transformer (TR2) ATR-J105-I<br />

Rating Primary AC 230V, 50Hz<br />

Secondary 19V, 0.526A<br />

Capacity 10VA<br />

Coil resistance Ω (at 22°C) Primary (WHT – WHT): 205 ± 10%<br />

Secondary (BRN – BRN): 2.0 ± 10%<br />

Thermal cut-off temp. 150°C<br />

17<br />

MQT5S-27YZJ<br />

Power Relay HH62S DC24V<br />

Coil rating DC 24V<br />

Coil resistance kΩ (at 23°C) 650 ± 10%<br />

Contact rating AC 250V, 10A

Outdoor Unit AE518SH<br />

Power Relay (PR) DFU24D1-F<br />

Coil rating DC 24V<br />

Coil resistance Ω (at 20°C) 650 ± 10%<br />

Contact rating AC 250V, 20A<br />

Starting Relay (SR) AMVL300A<br />

Coil rating AC 300V, 50Hz<br />

Coil resistance kΩ (at 23°C) 13.3 ± 2%<br />

Contact rating 20A AC<br />

Operating voltage AC 185 – 217V, 50Hz<br />

Return voltage AC 60 – 120V, 50Hz<br />

Thermostat (Defrost thermo. 23D) TRS02-12MSR<br />

Operating temp. °C ON 12 ± 2<br />

Diff. 8 deg. below<br />

Thermostat (Fan Speed Control 23S) MQT5S-27YZJ<br />

Switching temp. °C high ➞ LOW 23.5°C ±1.5<br />

Coil rating<br />

low<br />

AC 220-240V,<br />

➞ HIGH<br />

50Hz,<br />

27.0°C<br />

6W<br />

+0<br />

–3<br />

Contact Coil resistance rating Ω (at 20°C) AC 1.740 220V, ± 7% 3A<br />

4-way Valve (20S) LB64012 (Coil), V26-110B (Valve)<br />

Coil rating AC 220-240V, 50Hz, 6W<br />

Coil resistance Ω(at 20°C) 1.740 ± 7%<br />

Starting Capacitor C4; C5<br />

Capacitor 125 µF - 165V<br />

Resistor 18KΩ - 2W<br />

18

D OPERATING RANGE<br />

Function Temperature<br />

Cooling<br />

Maximum 35°C BS / 22°C BU 50°C BS<br />

Minimum 19°C BS / 14°C BU,5 -15°C BS<br />

21<br />

INDOOR UNIT OUTDOOR UNIT<br />

Indoor air Outdoor air<br />

intake temp. intake temp.<br />

Maximum 35°C BS / 22.5°C BU 52°C BS<br />

Minimum 19°C BS / 14°C BU,5 19°C BS<br />

Referred to the systems - ADR518CW - AER518SCL3 only (3 phase and low ambient version)<br />

Function Temperature<br />

Cooling<br />

INDOOR UNIT OUTDOOR UNIT<br />

Indoor air Outdoor air<br />

intake temp. intake temp.

REMOTE CONTROL UNIT<br />

E DIMENSIONAL DATA<br />

Indoor unit ADR518SW<br />

256<br />

200<br />

(OVERALL<br />

DIM.)<br />

20<br />

60<br />

26<br />

29<br />

692<br />

(OVERALL DIM.)<br />

2 - ø3.3<br />

(HOLE)<br />

6<br />

310<br />

5 - ø3,3<br />

(HOLE<br />

OPPOSITE SIDE)<br />

160<br />

38<br />

46 150 150 150 150 46<br />

125<br />

25<br />

120<br />

7<br />

15<br />

15<br />

8<br />

175<br />

120<br />

3<br />

665<br />

38 590<br />

665<br />

117 50<br />

22<br />

285<br />

(SUSPENSION BOLT<br />

PITCH)<br />

4 - ø3.1<br />

(HOLE)<br />

4<br />

100<br />

2<br />

120<br />

5<br />

310<br />

145<br />

1<br />

20<br />

32<br />

280<br />

750<br />

830<br />

20<br />

32<br />

6<br />

30<br />

170<br />

252<br />

30<br />

(SUSPENSION BOLT PITCH)<br />

LEGEND<br />

42<br />

35 220 220 35 195 74<br />

480<br />

210<br />

Refrigerant liquid line (Narrow tube - ø 6.35)<br />

Refrigerant gas line (Wide tube - ø 12.70)<br />

1<br />

8 - ø3,1<br />

(HOLE)<br />

20<br />

13<br />

2<br />

Drain connection (outside diam. 32)<br />

Electrical junction box<br />

3<br />

107<br />

4<br />

200<br />

107<br />

Mounting for suspention<br />

Duct connection for discharge (ø 200)<br />

5<br />

6<br />

Duct connection for suction<br />

Fresh air intake (ø 150)<br />

7<br />

8<br />

Dimension: mm

Outdoor Unit<br />

Air discharge<br />

538 146<br />

Air intake<br />

830<br />

307<br />

337<br />

4 – ø12 holes<br />

19<br />

23<br />

630<br />

Wide tube service valve<br />

ø12.7 (1/2")<br />

Narrow tube service valve<br />

ø6.35 (1/4")<br />

305<br />

61<br />

95<br />

Unit : mm

F FUNCTION<br />

1)ROOM TEMPERATURE CONTROL<br />

Cooling<br />

• Room temperature control is obtained by cycling the compressor ON and OFF under control of the room<br />

temperature sensor in the remote control unit.<br />

SET T + 0,5 ϒC<br />

TEMPERATURE T ϒC<br />

NOTA<br />

COMPRESSOR<br />

OUTDOOR<br />

FAN<br />

INDOOR<br />

FAN<br />

MORE THAN<br />

5 MINUTES<br />

ON<br />

THERMO OFF<br />

MORE THAN<br />

3 MINUTES<br />

• The control circuit will not attempt to turn the compressor ON until the compressor has been OFF for at<br />

least 3 minutes.<br />

To protect the compressor from stalling out when trying to start against the high side refrigerant pressure,<br />

the control circuit has a built-in automatic time delay to allow the internal pressure to equalize.<br />

• As a protective measure, the control circuit switches the compressor OFF after 5 minutes or more of<br />

compressor operation.<br />

• Thermo ON: When the room temperature is above T + 1°C (T°C is set temperature).<br />

Compressor ➔ ON.<br />

• Thermo OFF: When the room temperature in equal to or below set temperature T°C.<br />

Compressor ➔ OFF.<br />

24<br />

ROOM TEMPERATURE<br />

THERMO<br />

ON THERMO<br />

OFF<br />

MORE THAN<br />

WITHIN<br />

3 MINUTES<br />

WITHIN<br />

5 MINUTES<br />

THERMO<br />

ON THERMO<br />

OFF<br />

5 MINUTES 3 MINUTES 5 MINUTES<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

ON OFF<br />

ON<br />

OFF<br />

ON<br />

SET SPEED (MANUAL)

Heating<br />

SET TEMP.<br />

MORE THAN<br />

5 MINUTES<br />

T°C<br />

T-0.5°C<br />

COMPRESSOR<br />

OUTDOOR<br />

FAN<br />

INDOOR<br />

FAN<br />

STANDBY LAMP<br />

INDOOR HEAT<br />

EXCH. COIL<br />

TEMP. 35°C<br />

25°C<br />

SOLENOID COIL<br />

(4-WAY VALVE)<br />

OPERATION<br />

BUTTON<br />

OFF<br />

OFF<br />

OFF<br />

5 MINUTES<br />

THERMO<br />

OFF<br />

ON OFF<br />

ON OFF<br />

• The control circuit will not attempt to turn the compressor ON until the compressor has been OFF for at<br />

least 5 minutes. To protect the compressor from stalling out when trying to start against the high side<br />

refrigerant pressure, the control circuit has a built-in automatic time delay to allow the internal pressure to<br />

equalize.<br />

• As a protective measure, the control circuit switches the compressor OFF after 5 minutes or more of<br />

compressor operation.<br />

• Thermo ON: when the room temperature is below T -1°C (T°C is set temperature).<br />

Compressor ➔ ON.<br />

• Thermo OFF: when the room temperature is equal to or above set temperature T°C.<br />

Compressor ➔ OFF.<br />

25<br />

THERMO<br />

ON<br />

ROOM TEMP.<br />

THERMO<br />

OFF<br />

ON OFF<br />

ON OFF<br />

30 SECONDS 30 SECONDS<br />

LL SET SPEED LL SET SPEED LL<br />

❆ ❆<br />

OFF ON OFF ON OFF ON<br />

OFF<br />

5 MINUTES<br />

ON (REVERSING CYCLE)<br />

OFF ON<br />

L L = Low low speed ❆ COLD DRAFT PREVENTION<br />

❆

2)FREEZE PREVENTION (COOLING)<br />

• This function prevents freezing of the indoor heat exchange coil.<br />

• When the compressor has been running for 10 minutes or more and the temperature of the indoor heat<br />

exchange coil falls below –1°C, the control circuit stops the compressor for at least 6 minutes.<br />

SET<br />

TEMP.<br />

INDOOR<br />

HEAT EXCH.<br />

COIL TEMP.<br />

T +0.5°C<br />

T°C<br />

–1°C<br />

COMPRESSOR<br />

INDOOR<br />

FAN<br />

ROOM TEMP.<br />

MORE THAN<br />

10 MINUTES<br />

3)OVERLOAD PREVENTION (HEATING)<br />

6 MINUTES<br />

ON OFF ON ON OFF ON<br />

SET SPEED SET SPEED<br />

26<br />

MORE THAN<br />

10 MINUTES<br />

• This function prevents overheating of the indoor heat exchange coil.<br />

For indoor units ADR518HW only<br />

INDOOR HEAT<br />

EXCH. COIL<br />

TEMP. °C<br />

61<br />

59<br />

52<br />

49<br />

OUTDOOR<br />

FAN<br />

INDOOR<br />

FAN<br />

COMPRESSOR<br />

ON OFF ON<br />

H o M o L H ➔ H, M ➔ M, L ➔ M<br />

THERMO OFF<br />

THERMO ON<br />

• When the temperature of the indoor heat exchange coil rises above 59°C, and if the indoor fan is L (low<br />

speed), then the fan speed changes from L (low speed) to M (medium speed).<br />

• When the temperature of the indoor heat exchange coil rises above 61°C, the outdoor fan stops.<br />

ON<br />

AFTER<br />

6 MINUTES<br />

H = High speed<br />

M = Medium speed<br />

L = Low speed

4)DEFROSTING OPERATION (Heating)<br />

• When the capacity of the unit has been decreesed due to frosting up of the outdoor heat exchanger during<br />

heating, the temperature drop gradient is detected by the microcomputer-controlled temperature sensing<br />

system, and defrosting operation is started.<br />

DEFROSTING FLOWCHART<br />

Temperature of indoor heat<br />

exchanger coil is lower than<br />

45°C<br />

YES<br />

Temperature in indoor heat<br />

exchanger coil drops 0.8<br />

deg/6 min. or more and<br />

repeats 3 times continuously.<br />

YES<br />

Integrated operating time of<br />

compressor is more than<br />

20 minutes.<br />

YES<br />

Compressor ON<br />

A B C<br />

Temperature of outdoor heat<br />

exchange coil is higher than<br />

12°C.<br />

Integrated operating time of<br />

compressor is longer than<br />

3 hours<br />

Compressor keeps running<br />

for 5 minutes<br />

Defrosting thermo in the<br />

outdoor unit is OFF.<br />

(Below 4°C)<br />

27<br />

YES<br />

Defrosting begins.<br />

Cold-draft prevention.<br />

Release of defrosting.<br />

NO<br />

Integrated operating time of<br />

compressor is longer than<br />

1.5 hours<br />

YES<br />

Thermo OFF<br />

(Compressor OFF)<br />

YES<br />

Temperature of indoor heat<br />

exchanger coil is lower than<br />

53°C.<br />

YES<br />

Thermo ON<br />

(Compressor ON)<br />

Defrosting time is over<br />

11.5 minutes.

5)DEFROSTING MODE TIMING CHART<br />

COMPRESSOR<br />

OUTDOOR<br />

FAN<br />

SOLENOID COIL<br />

(4-WAY VALVE)<br />

INDOOR<br />

FAN<br />

STANDBY LAMP<br />

INDOOR HEAT<br />

EXCH. COIL<br />

TEMP. 35°C<br />

L L = Low low speed<br />

START OF DEFROSTING RELEASE OF DEFROSTING<br />

32 SECONDS<br />

MAX. 11 MINUTES 32 SECONDS<br />

ON OFF<br />

ON ON OFF<br />

ON<br />

ON OFF<br />

ON<br />

2 SECONDS<br />

ON OFF<br />

ON<br />

SET SPEED OFF SET SPEED<br />

LL<br />

6)OUTDOOR FAN SPEED CONTROL (COOLING)<br />

OFF ON ON OFF<br />

28<br />

2 SECONDS<br />

• To optimize performance of the air conditioner, the outdoor fan speed is switched automatically according<br />

to the outdoor temperature.<br />

• If the outdoor air temperature falls below 28.5°C, the fan speed switches to LOW.<br />

• If the outdoor air temperature rises above 31.5°C for 5 minutes or longer, the fan speed switches to HIGH.<br />

• This function does not become active in heating operation.<br />

OUTDOOR <strong>AIR</strong><br />

TEMPERATURE (°C)<br />

OUTDOOR FAN<br />

SPEED<br />

H = High speed<br />

L = Low speed<br />

31,5<br />

28,5<br />

H H<br />

L<br />

RELEASE OF<br />

COLD DRAFT PREVENTION

3) For AER518SCL3 only (3 phase and low ambient version)<br />

• When the outside ambient temperature decreases, the rotation speed of the outdoor fan is regulated by<br />

means of the outdoor heat-exchanger sensor to prevent liquid back.<br />

• The rotation speed varies with indoor temperature conditions (Hatching area).<br />

• The unit is protected against high pressure by means of the outside temperature sensor, and thus when<br />

the outside ambient temperature reaches 30°C respectively, the fan speed is forced to high.<br />

ROTATION SPEED OF FAN (rpm)<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

CONDITIONS: ROOM TEMPERATURE 19,4°C DB / 13,9°C WB 220V - 50 HZ<br />

▲<br />

-10 -5 0 5 10 15 20 25 30 35<br />

OUTDOOR AMBIENT TEMPERATURE (°C)<br />

29<br />

▲<br />

▲<br />

900 rpm<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲

G REFRIGERANT FLOW DIAGRAM<br />

COOLING MODE<br />

Indoor unit Outdoor unit<br />

HEAT PUMP MODE<br />

Indoor unit Outdoor unit<br />

30

H ELECTRIC WIRING DIAGRAMS WARNING<br />

TP1<br />

1<br />

2<br />

4<br />

5<br />

6<br />

7<br />

BLK<br />

WHT<br />

GRN/YEL<br />

BRN<br />

RED<br />

ORG<br />

YEL<br />

E<br />

FMI<br />

E<br />

GRY<br />

GRY<br />

WHT<br />

VLT<br />

ORG<br />

YEL<br />

BLK<br />

BRN<br />

PNK<br />

GRN/YEL<br />

LFS<br />

GRN/YEL<br />

1 2 3 4<br />

1 2 34<br />

11<br />

UNIT<br />

TH1 (COIL)<br />

2 2<br />

11 WHT<br />

SUP TH<br />

2 2 WHT<br />

9 9 GRY 1 1<br />

8 8 GRY 2 2<br />

TH2 (ROOM)<br />

77<br />

12P<br />

BODY 11 BLK<br />

66 VLT 66 VLT 4 THERMO 2 2 BLK<br />

55 ORG 55 ORG 9<br />

44 YEL 44<br />

YEL 1<br />

3 3 BLK 3 3 BLK 12<br />

11 WHT<br />

2 2 BRN BRN 2 2 BRN FMI PR<br />

2 2 WHT<br />

1 1<br />

11<br />

TR 235V P-O<br />

C1<br />

BLK<br />

BRN<br />

1 2 34<br />

1 2 34<br />

11<br />

22 UNIT<br />

TH1 (COIL)<br />

BLK<br />

SUP 11 WHT<br />

TH<br />

22 WHT<br />

9 9 GRY 11<br />

8 8 GRY 2 2<br />

TH2 (ROOM)<br />

77<br />

12P<br />

6 6 VLT 66 VLT 4 BODY 11 BLK<br />

5 5 ORG 55 ORG THERMO 2 2 BLK<br />

9<br />

4 4 YEL 4 4 YEL 1<br />

33 BLK 3 3 BLK 12<br />

2 2 BRN BRN 22 BRN<br />

1 1 WHT<br />

FMI PR<br />

2 2 WHT<br />

1 1 11<br />

TR<br />

235V P-C<br />

C1<br />

E<br />

DP<br />

PNK<br />

BLK<br />

BLK<br />

BLK<br />

BLK<br />

ADR518CW<br />

BLK<br />

11 BLK<br />

2 2 BLK<br />

1 1 BLU<br />

22 WHT<br />

GRY<br />

GRY<br />

WHT<br />

VLT<br />

ORG<br />

YEL<br />

BLK<br />

BRN<br />

PNK<br />

31<br />

RY<br />

PCB1<br />

1<br />

2<br />

FS<br />

PNK<br />

RED<br />

DP1<br />

DP2<br />

ADR518HW<br />

1 1 BLK<br />

SEC<br />

2 2 BRN<br />

REMOCON2 REMOCON1<br />

PCB1<br />

FMI<br />

1 1<br />

SS<br />

55<br />

1 1<br />

SS<br />

12 12<br />

E<br />

GRN/YEL<br />

19V<br />

S-O<br />

BLK<br />

BLK<br />

WHT<br />

GRN/YEL<br />

E<br />

GRN/YEL<br />

BLK<br />

BRN<br />

11<br />

2 2<br />

SEC<br />

TP1<br />

1<br />

2<br />

ORG 4<br />

S-0<br />

REMOTE<br />

CONTROL<br />

SWITCH<br />

19V<br />

11<br />

S S<br />

55<br />

BLK 11 BLK<br />

BLK 2 2 BLK<br />

LFS<br />

GRN/YEL<br />

E<br />

FS<br />

1<br />

2<br />

E<br />

REMOCON1<br />

To avoid electrical shock hazard, be<br />

sure to disconnect power before<br />

checking, servicing and/or cleaning<br />

any electrical parts<br />

REMOTE<br />

CONTROL<br />

SWITCH<br />

11<br />

SS<br />

1212<br />

REMOCON2<br />

DP1<br />

DP2<br />

BLU<br />

WHT<br />

11<br />

2 2<br />

GRN/YEL<br />

E DP BLK<br />

BLK

Outdoor Unit AE518SC<br />

AE518SC3<br />

34<br />

WARNING<br />

To avoid electrical shock hazard, be<br />

sure to disconnect power before<br />

checking, servicing and/or cleaning<br />

any electrical parts

Outdoor Unit AER518SCL3<br />

33<br />

WARNING<br />

To avoid electrical shock hazard, be<br />

sure to disconnect power before<br />

checking, servicing and/or cleaning<br />

any electrical parts

Outdoor Unit AE518SH<br />

34<br />

WARNING<br />

To avoid electrical shock hazard, be<br />

sure to disconnect power before<br />

checking, servicing and/or cleaning<br />

any electrical parts

Outdoor unit AE518SH3<br />

WARNING<br />

To avoid electrical shock hazard, be sure to<br />

disconnect power before checking, servicing<br />

and/or cleaning any electrical parts.<br />

35

Outdoor unit AER518SH3<br />

WARNING<br />

To avoid electrical shock hazard, be sure to<br />

disconnect power before checking, servicing<br />

and/or cleaning any electrical parts.<br />

36

I TROUBLESHOOTING (cooling model)<br />

1)CHECK BEFORE AND AFTER “TROUBLESHOOTING”<br />

a) Check power supply wiring.<br />

•WARNING:<br />

If the following troubleshooting must be done with power being supplied, be careful about any uninsulated<br />

live part that can cause ELECTRIC SHOCK.<br />

b) Check inter-unit wiring.<br />

•Check that inter-unit wiring (both the power wiring and control wiring) is correctly connected to the<br />

indoor unit from the outdoor unit.<br />

ADR518CW- AE518SC<br />

POWER SUPPLY<br />

50 Hz - Single-phase<br />

220/230/240 V<br />

ADR518CW- AER/AE518SCL3<br />

POWER SUPPLY<br />

50 Hz - 3-phase 400V<br />

4 Wires<br />

(c) Check power supply<br />

POWER<br />

SUPPLY<br />

GROUND<br />

POWER<br />

SUPPLY<br />

GROUND<br />

OUTDOOR INTER-UNIT INDOOR<br />

WIRING<br />

UNIT UNIT<br />

➀<br />

➁<br />

➂<br />

➃<br />

➄<br />

OUTDOOR INTER-UNIT INDOOR<br />

WIRING<br />

UNIT UNIT<br />

•Check that voltage is in specified range (± 10% of the rating).<br />

•Check that power is being supplied<br />

Single-phase systems Three-phase systems<br />

L<br />

N<br />

L1<br />

L2<br />

L3<br />

N<br />

230V<br />

➀<br />

➁<br />

➂<br />

➃<br />

➄<br />

➅<br />

➆<br />

➇<br />

37<br />

L1<br />

L2<br />

L3<br />

N<br />

400V<br />

400V<br />

➀<br />

➁<br />

➂<br />

➃<br />

➀<br />

➁<br />

➂<br />

➃<br />

➄<br />

➅<br />

➆<br />

➇<br />

400V<br />

230VV

2)<strong>SYSTEM</strong>ATIC CHART OF “TROUBLESHOOTING”<br />

Air conditioner does not operate.<br />

Circuit breaker trips (or<br />

fuse blows).<br />

Neither indoor unit nor<br />

outdoor unit runs.<br />

38<br />

When circuit breaker is<br />

set to ON, it trips in a<br />

few moments.<br />

Circuit breaker trips in<br />

several minutes after<br />

turning air conditioner<br />

ON.<br />

Power is not supplied.<br />

Function of compressor<br />

winding protection<br />

works.<br />

Indoor unit sensor are<br />

defective.<br />

Open or short circuit.<br />

Limit float switch has<br />

operated “OPEN”.<br />

Indoor unit installed upside<br />

- down.<br />

Measure insulation<br />

resistance of power<br />

supply wires.<br />

Check capacity of circuit<br />

breaker. Meaure resistance<br />

of electrical components.<br />

Check power supply.<br />

Check drain pump and<br />

drain hose.<br />

Reposition the indoor<br />

unit.

3)<strong>AIR</strong> <strong>CONDITIONER</strong> DOES NOT OPERATE<br />

(a) Circuit breaker trips (or fuse blows)<br />

• When circuit breaker is set to ON, it trips in a few moments. (Resetting is not possible).<br />

• Measure insulation resistance there is a possibility of ground fault. If resistance value is 1MΩ or less,<br />

insulation is defective.<br />

ADR518CW - AE518SC<br />

Power<br />

supply<br />

Circuit<br />

breaker<br />

ADR518CW- AER/AE518SCL3<br />

Power<br />

sypply<br />

Unità<br />

esterna<br />

L1<br />

L2<br />

L3<br />

N<br />

5<br />

6<br />

7<br />

8<br />

Circuit<br />

breaker<br />

• Set circuit breaker to OFF.<br />

➀ Remove power supply wires<br />

from terminal plate in outdoor<br />

unit.<br />

• Measure insulation resistance of<br />

power supply wires.<br />

➁ Remove inter-unit wires from<br />

terminal plate in outdoor unit.<br />

• Measure insulation resistance of<br />

outdoor unit.<br />

➂ Remove inter-unit wires from<br />

terminal plate in intdoor unit.<br />

• Measure insulation resistance of<br />

intdoor unit.<br />

➃ Measure insulation resistance of<br />

inter-unit wires.<br />

�<br />

Unità Outdoor<br />

�<br />

Unità<br />

�<br />

esterna unit esterna<br />

�<br />

x 1 x x<br />

x 2 x x<br />

3 �<br />

4 4 x x<br />

5<br />

6<br />

5<br />

8<br />

7<br />

�<br />

Ground<br />

Inter-uni<br />

wiring<br />

x<br />

x<br />

x<br />

x<br />

5<br />

6<br />

�7<br />

8 Ground<br />

5 1<br />

6<br />

7<br />

8 2<br />

�<br />

4<br />

38<br />

1<br />

2<br />

�<br />

4<br />

5<br />

�<br />

Unità<br />

esterna<br />

Outdoor<br />

unit<br />

� �<br />

Unità<br />

esterna<br />

�<br />

x x<br />

x x<br />

OK<br />

OK<br />

x x<br />

x x<br />

Inter-unit<br />

wiring<br />

Do rewiring<br />

Insulation of outdoor<br />

unit is defective.<br />

Insulation of indoor unit<br />

is defective.<br />

Do rewiring.<br />

Indoor<br />

unit<br />

1<br />

2<br />

�<br />

4<br />

Indoor<br />

unit<br />

YES<br />

YES<br />

Measure insulation resistance<br />

of electrical parts in<br />

outdoor unit.<br />

Measure insulation resistance<br />

of electrical parts in<br />

indoor unit.

(b) Circuit breaker trips in several minutes after turning air conditioner ON.<br />

• There is a possibility of short circuit.<br />

Check capacity of circuit breaker.<br />

Capacity of circuit breaker is suitable?<br />

YES<br />

Measure resistance of compressor<br />

motor winding.<br />

OK<br />

Measure resistance of outdoor fan<br />

motor winding.<br />

(c) Neither indoor unit nor outdoor unit runs<br />

Check power supply.<br />

Is power being supplied to wall<br />

receptacle?<br />

Leds of remote control unit are light<br />

Check is drain flow prevented?<br />

NO<br />

Check if the drain pump is working.<br />

Measure resistance of drain pump<br />

motor winding.<br />

YES<br />

Check function of limit float switch.<br />

Float in high position: open circuit.<br />

Float in down position: short circuit.<br />

(Normal condition)<br />

YES<br />

Check installation of indoor unit is<br />

it installed upside - down?<br />

OK<br />

NO<br />

NO<br />

Replace it with suitable one.<br />

(larger capacity).<br />

40<br />

YES<br />

NO<br />

NO<br />

YES<br />

Circuit breaker is<br />

tripped.<br />

Power failure.<br />

Outdoor unit<br />

AE518SC3<br />

AER518SCL3ONLY<br />

Measure coil resistance of<br />

magnetic contactor. (MG or<br />

52C)<br />

Reset the breaker.<br />

Wait for recovery or contact<br />

power company.<br />

Check drain hose.<br />

Replace drain pump.<br />

Replace limit float switch.<br />

Reposition the indoor unit.

(d) Check fuse on PCB Ass’y in indoor unit<br />

Check fuse on PCB Ass’y in<br />

indoor unit for continuity. (F)<br />

Measure resistance of primary<br />

winding of transformer.<br />

(TR)<br />

Measure resistance of indoor<br />

fan motor winding. (FMI)<br />

Measure resistance of drain<br />

pump winding.<br />

If fuse blows, there is a possibility of short circuit.<br />

OK<br />

OK<br />

e) Check transformer in indoor unit<br />

Check whether transformere is detective.<br />

Measure resistance of primary and<br />

secondary winding. (TR)<br />

f) Check indoor fan motor protector<br />

Wait for 30 minutes and then try to run.<br />

Air conditioner does not run again.<br />

Indoor fan motor internal protector trips.<br />

Check fan rotation. Turn<br />

fan gently once or twice<br />

by hand.<br />

OK<br />

Air conditioner starts running.<br />

Fan cannot<br />

be turned<br />

4) ONLY OUTDOOR UNIT DOES NOT RUN<br />

39<br />

Measure coil resistance of power<br />

relay or magnetic contactor in outdoor<br />

unit. (PR - MG - 52C)<br />

PCB Ass’y in indoor unit is defective.<br />

Check fan casing for<br />

foreign matter on inside.<br />

Fan motor burnout or<br />

foreign matter in bearing.<br />

a) Outdoor unit does not run when air conditioner is in following conditions.<br />

• During thermo OFF.<br />

• During freeze prevention (for at least 6 minutes).<br />

• During drain pump works (for at least 12 minutes).<br />

b) PCB Ass’y in indoor unit is defective.<br />

Remove foreign matter<br />

or repair.<br />

Repair or replace.

•Check power relay in outdoor unit (only for AE518SC)<br />

• Check coil resistance of power<br />

relay.<br />

OK<br />

• PCB Ass’y defective.<br />

•Check negative phase relay (only for AE518SC/SCL3-AER/AE518SH3)<br />

• Check negative phase relay to<br />

see if it has operated. (47C)<br />

YES<br />

• Rewire power supply wires.<br />

5) COMPRESSOR MOTOR DOES NOT RUN (only for AE518SC)<br />

a) Single phase systems 230V - 1 - 50 Hz<br />

• Check compressor motor capacitor.<br />

(C1)<br />

OK<br />

• Measure resistance of compressor<br />

motor winding.<br />

42<br />

• Check overload relay and/or<br />

compressor motor internal protector.<br />

(OLR - 49C)<br />

It has tripped<br />

• Is outdoor heat exchanger coil<br />

dirty or are there obstacles near<br />

air suction inlet of outdoor unit?<br />

NO<br />

• Check power supply voltage. Is<br />

voltage abnormally low?<br />

NO<br />

• Is temperature of compressor<br />

abnormally high?<br />

YES<br />

• Refrigerant gas shortage.

) Three - phase systems 400V - 3N - 50 Hz<br />

• Measure resistance of compressor<br />

motor winding.<br />

Is outdoor heat exchanger coil dirty<br />

or are there obstacles near air suction<br />

inlet?<br />

YES<br />

Clean heat exchanger or remove<br />

obstacles.<br />

• Check compressor motor overcurrent<br />

relay (51C).<br />

It’s operated<br />

• Check power supply voltage. Is<br />

voltage abnormally low?<br />

NO<br />

• Check compressor.<br />

There is a possibility of locked<br />

rotor.<br />

NO<br />

90% or more of<br />

rated voltage<br />

Is temperature of compressor<br />

abnormally high?<br />

43<br />

YES<br />

Refrigerant gas shortage.<br />

YES<br />

Charge refrigerant gas.

L SOME PARTS OF <strong>AIR</strong> <strong>CONDITIONER</strong> DO NOT OPERATE<br />

1) ONLY INDOOR FAN DOES NOT RUN<br />

Check fan rotation. Turn fan gently<br />

once or twice by hand.<br />

Fan turn<br />

normal<br />

Check fan motor capacitor.<br />

OK<br />

Measure resistance of fan motor<br />

winding.<br />

OK<br />

Check output of fan motor terminals<br />

on PCB Ass’y.<br />

Fan cannot<br />

be turned<br />

NO<br />

NO<br />

44<br />

OK<br />

Check fan casing for<br />

foreign matter on inside.<br />

Fan motor burnout or<br />

foreign matter in bearing.<br />

Replace capacitor.<br />

Replace fan motor.<br />

2) FUNCTION OF OUTDOOR FAN SPEED CONTROL DOES NOT WORK PROPERLY<br />

(only for SAP-C188E5)<br />

• Check thermostat in outdoor<br />

unit. (23S)<br />

3) ONLY OUTDOOR FAN DOES NOT RUN<br />

Check fan rotation. Turn fan gently<br />

once or twice by hand.<br />

Measure the resistance of outdoor<br />

fan motor winding.<br />

OK<br />

Check fan motor capacitor.<br />

Only for low ambient version<br />

units (AE518SCL3)<br />

Fan cannot<br />

be turned.<br />

Check fan casing for<br />

foreign matter on inside.<br />

Fan motor burnout or<br />

foreign matter in bearing.<br />

Remove foreign<br />

matter or repair.<br />

Repair or replace.<br />

• Check electronic fan speed regulator<br />

(SSR)<br />

Remove foreign<br />

matter or repair.<br />

Repair or replace.<br />

Defrost controller (POW-C92 GH)<br />

is defective in outdoor unit.

M <strong>AIR</strong> <strong>CONDITIONER</strong> OPERATES, BUT ABNORMALITIES OCCUR<br />

a)<br />

POOR COOLING<br />

Refrigerant<br />

flow failure<br />

Air circulation<br />

is a little<br />

b) Excessive cooling<br />

Is remote control unit installed at a<br />

place where it can detect room temperature<br />

properly!<br />

Check installation position of remote<br />

control unit.<br />

Does cool air from air conditioner<br />

reach position directly?<br />

Is cooling load too large?<br />

Measure temperatures of<br />

suction and discharge air<br />

of air conditioner.<br />

Check for clogging of air filter.<br />

Refrigerant gas shortage.<br />

Compressor is defective.<br />

Service valves are not fully open.<br />

Air filter is clogged.<br />

Is fan speed set to LOW?<br />

Long extension of ducts.<br />

Refrigerant tubes between indoor<br />

and outdoor units are not insulated.<br />

45<br />

YES<br />

Temperature difference<br />

is small<br />

Temperature difference between<br />

suction and discharge air is large<br />

enough (approx. 10°C or more).<br />

NO<br />

Change installation position of<br />

remote control unit.<br />

Review cooling load estimate.<br />

Possibility of<br />

gas shortage.<br />

Air filter is clogged<br />

Charge refrigerant gas.<br />

Replace.<br />

Open the valves fully.<br />

Charge refrigerant<br />

gas (R22<br />

R407C)<br />

Clean filter<br />

Clean filter in the air intake grille.<br />

Set the fan speed to either MEDIUM<br />

or HIGH.<br />

Use the booster cable.<br />

Insulate wide and narrow tubes<br />

separately.<br />

Change installation position of remote<br />

control unit.

N TROUBLESHOOTING (HEATING MODEL)<br />

1)CHECK BEFORE AND AFTER “TROUBLESHOOTING”<br />

a) Check power supply wiring.<br />

•WARNING:<br />

If the following troubleshooting must be done with power being supplied, be careful about any<br />

uninsulated live part that can cause ELECTRIC SHOCK.<br />

•Check that power supply wires are correctly connected to terminals:<br />

Single-phase system –No. 1 and No. 2 on the terminal plate in the outdoor unit.<br />

Three-phase system – ADR518HW/AE518SH - No. 1, 2, on the terminal<br />

plate in the outdoor unit.<br />

–ADR518HW / AE/AER518SH3 - No. 8, 9, 10 and 11 on terminal plate in the<br />

outdoor unit.<br />

b) Check inter-unit wiring.<br />

•Check that inter-unit wiring (both the power wiring and control wiring) is correctly connected to the<br />

indoor unit from the outdoor unit.<br />

ADR518HW - AE518SH<br />

POWER SUPPLY<br />

50 Hz - Single-phase<br />

220/230/240 V<br />

POWER<br />

SUPPLY<br />

ADR518HW - AE/AER518SH3<br />

POWER SUPPLY<br />

50 Hz - 3-phase 400V<br />

4 Wires<br />

POWER<br />

SUPPLY<br />

GROUND<br />

GROUND<br />

L1<br />

L2<br />

L3<br />

N<br />

OUTDOOR INTER-UNIT INDOOR<br />

UNIT POWER WIRING UNIT<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

GROUND<br />

INTER-UNIT<br />

CONTROL WIRING<br />

OUTDOOR POWER WIRING INDOOR<br />

UNIT UNIT<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

INTER-UNIT<br />

GROUND<br />

INTER-UNIT<br />

CONTROL WIRING<br />

46<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�

(c) Check power supply<br />

• Check that voltage is in specified range (± 10% of the rating).<br />

• Check that power is being supplied<br />

Single-phase systems Three-phase systems<br />

L<br />

N<br />

220V<br />

(d) Check lead wires and connectors in indoor and outdoor units.<br />

• Check that coating of lead wires is not damaged.<br />

• Check that lead wires and connectors are connected firmly.<br />

• Check that wiring is correct.<br />

L1<br />

L2<br />

L3<br />

N<br />

47<br />

400V<br />

400V<br />

400V<br />

230V

2)<strong>SYSTEM</strong>ATIC CHART OF “TROUBLESHOOTING”<br />

Air conditioner does not operate.<br />

Circuit breaker trips (or<br />

fuse blows).<br />

Neither indoor unit nor<br />

outdoor unit runs.<br />

48<br />

When circuit breaker is<br />

set to ON, it trips in a<br />

few moments.<br />

Circuit breaker trips in<br />

several minutes after<br />

turning air conditioner<br />

ON.<br />

Power is not supplied.<br />

Function of compressor<br />

winding protection<br />

works.<br />

Indoor unit sensor are<br />

defective.<br />

Open or short circuit.<br />

Limit float switch has<br />

operated “OPEN”.<br />

Indoor unit installed<br />

upside - down.<br />

Measure insulation<br />

resistance of power<br />

supply wires.<br />

Check capacity of circuit<br />

breaker. Meaure<br />

resistance of electrical<br />

components.<br />

Check power supply.<br />

Check drain pump and<br />

drain hose.<br />

Reposition the indoor<br />

unit.

3)<strong>AIR</strong> <strong>CONDITIONER</strong> DOES NOT OPERATE<br />

(a) Circuit breaker trips (or fuse blows)<br />

•When circuit breaker is set to ON, it trips in a few moments. (Resetting is not possible).<br />

•Measure insulation resistance there is a possibility of ground fault. If resistance value is 1MΩ or less,<br />

insulation is defective.<br />

ADR518HW- AE518SH<br />

Power<br />

supply<br />

Circuit<br />

breaker<br />

ADR518CW - AE/AER518SH3<br />

Power<br />

supply<br />

L1<br />

L2<br />

L3<br />

N<br />

Circuit<br />

breaker<br />

� � �<br />

Unità Outdoor Unità<br />

esterna unit esterna<br />

�<br />

x x<br />

x x<br />

x<br />

x<br />

3<br />

4<br />

5<br />

�<br />

6<br />

Ground<br />

7<br />

8<br />

Unitx<br />

x<br />

x<br />

x<br />

49<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Inter-unit<br />

power wiring<br />

x x<br />

x x<br />

x x<br />

x x<br />

Inter-unit<br />

control wiring<br />

� � �<br />

Outdoor<br />

unit<br />

Unità<br />

esterna<br />

�<br />

x x<br />

x x<br />

�<br />

Ground<br />

Unità<br />

esterna<br />

8<br />

Inter-unit<br />

power wiring<br />

x x<br />

x x<br />

x x<br />

x x<br />

Inter-unit<br />

control wiring<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Indoor<br />

unit<br />

Indoor<br />

unit

• Set circuit breaker to OFF.<br />

➀ Remove power supply wires<br />

from terminal plate in outdoor<br />

unit.<br />

• Measure insulation resistance of<br />

power supply wires.<br />

➁ Remove inter-unit wires from<br />

terminal plate in outdoor unit.<br />

• Measure insulation resistance of<br />

outdoor unit.<br />

➂ Remove inter-unit wires from<br />

terminal plate in intdoor unit.<br />

• Measure insulation resistance of<br />

intdoor unit.<br />

➃ Measure insulation resistance of<br />

inter-unit wires.<br />

OK<br />

OK<br />

50<br />

Do rewiring<br />

Insulation of outdoor<br />

unit is defective.<br />

Insulation of indoor unit<br />

is defective.<br />

Do rewiring.<br />

YES<br />

YES<br />

Measure insulation<br />

resistance of electrical parts<br />

in outdoor unit.<br />

Measure insulation<br />

resistance of electrical parts<br />

in indoor unit.

(b) Circuit breaker trips in several minutes after turning air conditioner ON.<br />

• There is a possibility of short circuit.<br />

Check capacity of circuit breaker.<br />

Capacity of circuit breaker is<br />

suitable?<br />

YES<br />

Measure resistance of outdoor fan<br />

motor winding.<br />

OK<br />

Measure resistance of indoor fan<br />

motor winding.<br />

(c) Neither indoor unit nor outdoor unit runs (leds of remote control unit are light)<br />

Check power supply.<br />

Is power being supplied to wall<br />

receptacle?<br />

Check is drain flow prevented?<br />

NO<br />

Check if the drain pump is working.<br />

Measure resistance of drain pump<br />

motor winding.<br />

YES<br />

Check function of limit float switch.<br />

Float in high position: open circuit.<br />

Float in down position: short circuit.<br />

(Normal condition)<br />

YES<br />

Check installation of indoor unit it<br />

is installed upside - down?<br />

OK<br />

NO<br />

NO<br />

Replace it with suitable one.<br />

(larger capacity).<br />

In case of Heating<br />

operation:<br />

Measure resistance of 4-way<br />

valve’s winding. (20S or SC).<br />

51<br />

YES<br />

NO<br />

NO<br />

YES<br />

Circuit breaker is<br />

tripped.<br />

Power failure.<br />

Reset the breaker.<br />

Wait for recovery or<br />

contact power company.<br />

Check drain hose.<br />

Replace drain pump.<br />

Replace limit float switch.<br />

Reposition the indoor unit.

(d) Check fuse on PCB Ass’y in indoor unit<br />

Check fuse on PCB Ass’y in<br />

indoor unit for continuity.<br />

Measure resistance of<br />

primary winding of<br />

transformer.<br />

Measure resistance of<br />

indoor fan motor winding.<br />

Measure resistance of drain<br />

pump winding.<br />

If fuse blows, there is a possibility of short circuit.<br />

OK<br />

OK<br />

e) Check transformer in indoor unit<br />

Check whether transformere is<br />

detective.<br />

Measure resistance of primary and<br />

secondary winding.<br />

f) Check indoor fan motor protector<br />

Wait for 30 minutes and then try to run.<br />

Air conditioner does not run again.<br />

Indoor fan motor internal protector trips.<br />

Check fan rotation. Turn<br />

fan gently once or twice<br />

by hand.<br />

OK<br />

Air conditioner starts running.<br />

Fan cannot<br />

be turned<br />

4) ONLY OUTDOOR UNIT DOES NOT RUN<br />

52<br />

Measure coil resistance of power<br />

relay or magnetic contactor in<br />

outdoor unit.<br />

PCB Ass’y in indoor unit is<br />

defective.<br />

Check fan casing for<br />

foreign matter on inside.<br />

Fan motor burnout or<br />

foreign matter in bearing.<br />

a) Outdoor unit does not run when air conditioner is in following conditions.<br />

• During thermo OFF.<br />

• During freeze prevention (for at least 6 minutes).<br />

• During drain pump works (for at least 12 minutes).<br />

b) PCB Ass’y in indoor unit is defective.<br />

Remove foreign matter<br />

or repair.<br />

Repair or replace.

O SOME PARTS OF <strong>AIR</strong> <strong>CONDITIONER</strong> DO NOT OPERATE<br />

1) ONLY INDOOR FAN DOES NOT RUN<br />

Check fan rotation. Turn fan gently<br />

once or twice by hand.<br />

Fan turn<br />

normal<br />

Check fan motor capacitor.<br />

OK<br />

Measure resistance of fan motor<br />

winding.<br />

OK<br />

Check output of fan motor terminals<br />

on PCB Ass’y.<br />

Fan cannot<br />

be turned<br />

2) ONLY OUTDOOR FAN DOES NOT RUN<br />