You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

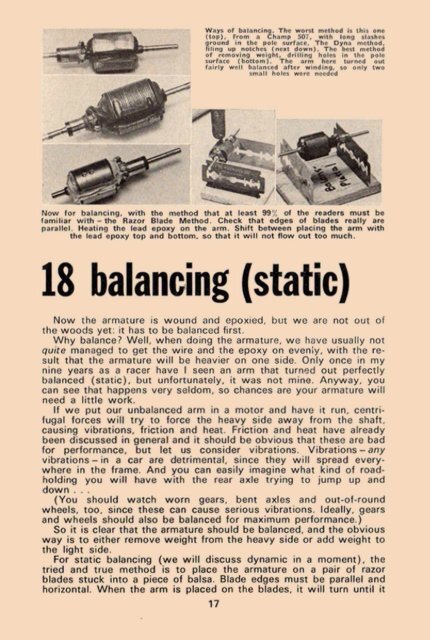

Ways of balancing. The worst method is this one<br />

(top), from a Champ 507. with long slashes<br />

ground in the pole surface. The Dyna method,<br />

filing up notches (next down). The best method<br />

of removing weight, drilling holes in the pole<br />

surface (bottom). The arm here turned out<br />

fairly well balanced after winding, so only two<br />

small holes were needed<br />

Now for balancing, with the method that at least 99% of the readers m ust be<br />

familiar with - the Razor Blade Method. Check that edges of blades really are<br />

parallel. Heating the lead epoxy on the arm. Shift between placing the arm with<br />

the lead epoxy top and bottom, so that it will not flow out too much.<br />

18 balancing (static)<br />

Now the armature is wound and epoxied. but we are not out of<br />

the woods yet: it has to be balanced first.<br />

Why balance? Well, when doing the armature, we have usually not<br />

quite managed to get the wire and the epoxy on evenly, with the result<br />

that the armature will be heavier on one side. Only once in my<br />

nine years as a racer have I seen an arm that turned out perfectly<br />

balanced (static), but unfortunately, it was not mine. Anyway, you<br />

can see that happens very seldom, so chances are your armature will<br />

need a little work.<br />

If we put our unbalanced arm in a motor and have it run. centrifugal<br />

forces will try to force the heavy side away from the shaft,<br />

causing vibrations, friction and heat. Friction and heat have already<br />

been discussed in general and it should be obvious that these are bad<br />

for performance, but let us consider vibrations. Vibrations - any<br />

vibrations - in a car are detrimental, since they will spread everywhere<br />

in the frame. And you can easily imagine what kind of roadholding<br />

you will have with the rear axle trying to jump up and<br />

down . . .<br />

(You should watch worn gears, bent axles and out-of-round<br />

wheels, too, since these can cause serious vibrations. Ideally, gears<br />

and wheels should also be balanced for maximum performance.)<br />

So it is clear that the armature should be balanced, and the obvious<br />

way is to either remove weight from the heavy side or add weight to<br />

the light side.<br />

For static balancing (we will discuss dynamic in a moment), the<br />

tried and true method is to place the armature on a pair of razor<br />

blades stuck into a piece of balsa. Blade edges must be parallel and<br />

horizontal. When the arm is placed on the blades, it will turn until it<br />

17