MEATing POINT Magazine: #12 / 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PROCESSING<br />

operations with minimal residual<br />

amounts.<br />

Picture 4: IVM Vario Mix series for<br />

fast and gentle mixing in inserts and<br />

mixing of delicacy products, but also<br />

perfect for ham (extremely much<br />

faster than Tumbler) and salami<br />

After presenting all the machine<br />

components of a continuous production<br />

line, it should be pointed out that<br />

a production line is not only the<br />

combination of individual machines,<br />

but an integrated control system<br />

with recipe management, flexible<br />

process steps and data recording<br />

facilities that ensure the best usage<br />

of the selected degree of automation<br />

of the meat processing company.<br />

In the field of portioning, Inotec<br />

is the leader with the Giromatic<br />

high-performance automatic tying<br />

machines. In combination with<br />

a filler, the sausage portions are<br />

exactly formed and separated by a<br />

special thread. Inotec sausage slicers<br />

ensure that after the maturation or<br />

the cooking process is finished, the<br />

portions will be separated .<br />

About the author:<br />

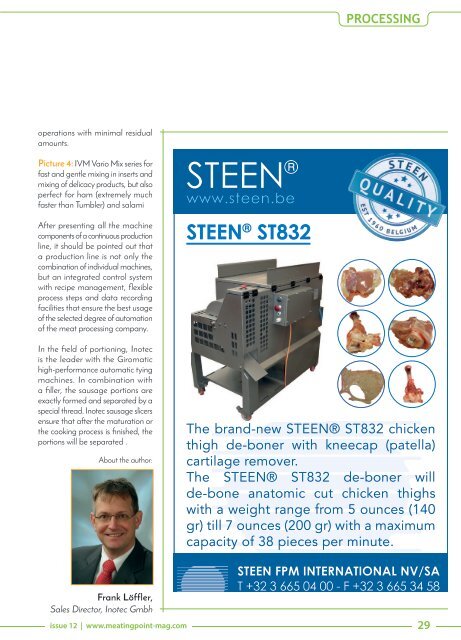

STEEN ®<br />

www.steen.be<br />

STEEN ® ST832<br />

The brand-new STEEN® ST832 chicken<br />

thigh de-boner with kneecap (patella)<br />

cartilage remover.<br />

The STEEN® ST832 de-boner will<br />

de-bone anatomic cut chicken thighs<br />

with a weight range from 5 ounces (140<br />

gr) till 7 ounces (200 gr) with a maximum<br />

capacity of 38 pieces per minute.<br />

Frank Löffler,<br />

Sales Director, Inotec Gmbh<br />

issue 12 | www.meatingpoint-mag.com<br />

STEEN FPM INTERNATIONAL NV/SA<br />

T +32 3 665 04 00 - F +32 3 665 34 58<br />

info@steen.be - www.steen.be<br />

29