MEATing POINT Magazine: #12 / 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PACKAGING<br />

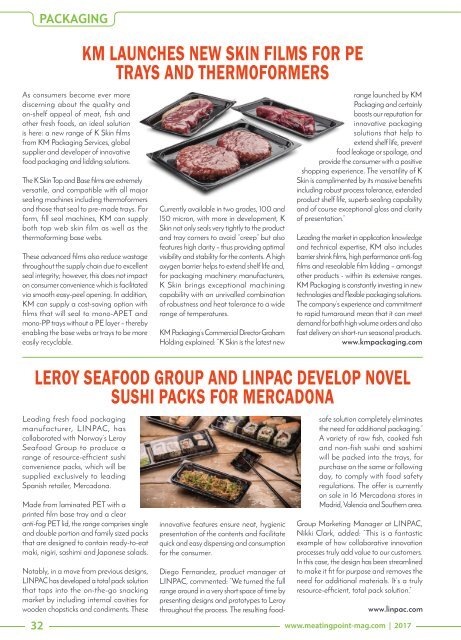

As consumers become ever more<br />

discerning about the quality and<br />

on-shelf appeal of meat, fish and<br />

other fresh foods, an ideal solution<br />

is here: a new range of K Skin films<br />

from KM Packaging Services, global<br />

supplier and developer of innovative<br />

food packaging and lidding solutions.<br />

KM LAUNCHES NEW SKIN FILMS FOR PE<br />

TRAYS AND THERMOFORMERS<br />

The K Skin Top and Base films are extremely<br />

versatile, and compatible with all major<br />

sealing machines including thermoformers<br />

and those that seal to pre-made trays. For<br />

form, fill seal machines, KM can supply<br />

both top web skin film as well as the<br />

thermoforming base webs.<br />

These advanced films also reduce wastage<br />

throughout the supply chain due to excellent<br />

seal integrity; however, this does not impact<br />

on consumer convenience which is facilitated<br />

via smooth easy-peel opening. In addition,<br />

KM can supply a cost-saving option with<br />

films that will seal to mono-APET and<br />

mono-PP trays without a PE layer – thereby<br />

enabling the base webs or trays to be more<br />

easily recyclable.<br />

Currently available in two grades, 100 and<br />

150 micron, with more in development, K<br />

Skin not only seals very tightly to the product<br />

and tray corners to avoid “creep” but also<br />

features high clarity – thus providing optimal<br />

visibility and stability for the contents. A high<br />

oxygen barrier helps to extend shelf life and,<br />

for packaging machinery manufacturers,<br />

K Skin brings exceptional machining<br />

capability with an unrivalled combination<br />

of robustness and heat tolerance to a wide<br />

range of temperatures.<br />

KM Packaging’s Commercial Director Graham<br />

Holding explained: “K Skin is the latest new<br />

range launched by KM<br />

Packaging and certainly<br />

boosts our reputation for<br />

innovative packaging<br />

solutions that help to<br />

extend shelf life, prevent<br />

food leakage or spoilage, and<br />

provide the consumer with a positive<br />

shopping experience. The versatility of K<br />

Skin is complimented by its massive benefits<br />

including robust process tolerance, extended<br />

product shelf life, superb sealing capability<br />

and of course exceptional gloss and clarity<br />

of presentation.”<br />

Leading the market in application knowledge<br />

and technical expertise, KM also includes<br />

barrier shrink films, high performance anti-fog<br />

films and resealable film lidding – amongst<br />

other products - within its extensive ranges.<br />

KM Packaging is constantly investing in new<br />

technologies and flexible packaging solutions.<br />

The company’s experience and commitment<br />

to rapid turnaround mean that it can meet<br />

demand for both high volume orders and also<br />

fast delivery on short-run seasonal products.<br />

www.kmpackaging.com<br />

LEROY SEAFOOD GROUP AND LINPAC DEVELOP NOVEL<br />

SUSHI PACKS FOR MERCADONA<br />

Leading fresh food packaging<br />

manufacturer, LINPAC, has<br />

collaborated with Norway’s Leroy<br />

Seafood Group to produce a<br />

range of resource-efficient sushi<br />

convenience packs, which will be<br />

supplied exclusively to leading<br />

Spanish retailer, Mercadona.<br />

Made from laminated PET with a<br />

printed film base tray and a clear<br />

anti-fog PET lid, the range comprises single<br />

and double portion and family sized packs<br />

that are designed to contain ready-to-eat<br />

maki, nigiri, sashimi and Japanese salads.<br />

Notably, in a move from previous designs,<br />

LINPAC has developed a total pack solution<br />

that taps into the on-the-go snacking<br />

market by including internal cavities for<br />

wooden chopsticks and condiments. These<br />

innovative features ensure neat, hygienic<br />

presentation of the contents and facilitate<br />

quick and easy dispensing and consumption<br />

for the consumer.<br />

Diego Fernandez, product manager at<br />

LINPAC, commented: “We turned the full<br />

range around in a very short space of time by<br />

presenting designs and prototypes to Leroy<br />

throughout the process. The resulting foodsafe<br />

solution completely eliminates<br />

the need for additional packaging.”<br />

A variety of raw fish, cooked fish<br />

and non-fish sushi and sashimi<br />

will be packed into the trays, for<br />

purchase on the same or following<br />

day, to comply with food safety<br />

regulations. The offer is currently<br />

on sale in 16 Mercadona stores in<br />

Madrid, Valencia and Southern area.<br />

Group Marketing Manager at LINPAC,<br />

Nikki Clark, added: “This is a fantastic<br />

example of how collaborative innovation<br />

processes truly add value to our customers.<br />

In this case, the design has been streamlined<br />

to make it fit for purpose and removes the<br />

need for additional materials. It’s a truly<br />

resource-efficient, total pack solution.”<br />

www.linpac.com<br />

32 www.meatingpoint-mag.com | <strong>2017</strong>