You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Customer : ENV<br />

Type : A<strong>320</strong><br />

Rev. Date : Nov 01, 2016<br />

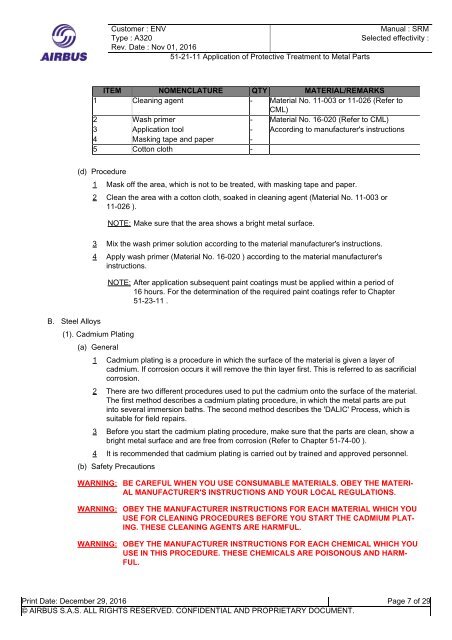

<strong>51</strong>-<strong>21</strong>-<strong>11</strong> Application of Protective Treatment to Metal Parts<br />

Manual : <strong>SRM</strong><br />

Selected effectivity :<br />

ITEM NOMENCLATURE QTY MATERIAL/REMARKS<br />

1 Cleaning agent - Material No. <strong>11</strong>-003 or <strong>11</strong>-026 (Refer to<br />

CML)<br />

2 Wash primer - Material No. 16-020 (Refer to CML)<br />

3 Application tool - According to manufacturer's instructions<br />

4 Masking tape and paper -<br />

5 Cotton cloth -<br />

B. Steel Alloys<br />

(d) Procedure<br />

1 Mask off the area, which is not to be treated, with masking tape and paper.<br />

2 Clean the area with a cotton cloth, soaked in cleaning agent (Material No. <strong>11</strong>-003 or<br />

<strong>11</strong>-026 ).<br />

NOTE: Make sure that the area shows a bright metal surface.<br />

3 Mix the wash primer solution according to the material manufacturer's instructions.<br />

4 Apply wash primer (Material No. 16-020 ) according to the material manufacturer's<br />

instructions.<br />

(1). Cadmium Plating<br />

(a) General<br />

NOTE: After application subsequent paint coatings must be applied within a period of<br />

16 hours. For the determination of the required paint coatings refer to Chapter<br />

<strong>51</strong>-23-<strong>11</strong> .<br />

1 Cadmium plating is a procedure in which the surface of the material is given a layer of<br />

cadmium. If corrosion occurs it will remove the thin layer first. This is referred to as sacrificial<br />

corrosion.<br />

2 There are two different procedures used to put the cadmium onto the surface of the material.<br />

The first method describes a cadmium plating procedure, in which the metal parts are put<br />

into several immersion baths. The second method describes the 'DALIC' Process, which is<br />

suitable for field repairs.<br />

3 Before you start the cadmium plating procedure, make sure that the parts are clean, show a<br />

bright metal surface and are free from corrosion (Refer to Chapter <strong>51</strong>-74-00 ).<br />

4 It is recommended that cadmium plating is carried out by trained and approved personnel.<br />

(b) Safety Precautions<br />

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERI-<br />

AL MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.<br />

WARNING: OBEY THE MANUFACTURER INSTRUCTIONS FOR EACH MATERIAL WHICH YOU<br />

USE FOR CLEANING PROCEDURES BEFORE YOU START THE CADMIUM PLAT-<br />

ING. THESE CLEANING AGENTS ARE HARMFUL.<br />

WARNING: OBEY THE MANUFACTURER INSTRUCTIONS FOR EACH CHEMICAL WHICH YOU<br />

USE IN THIS PROCEDURE. THESE CHEMICALS ARE POISONOUS AND HARM-<br />

FUL.<br />

Print Date: December 29, 2016 Page 7 of 29<br />

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.