Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Customer : ENV<br />

Type : A<strong>320</strong><br />

Rev. Date : Nov 01, 2016<br />

<strong>51</strong>-<strong>21</strong>-<strong>11</strong> Application of Protective Treatment to Metal Parts<br />

Manual : <strong>SRM</strong><br />

Selected effectivity :<br />

(c) Cadmium Plating (Immersion Procedure)<br />

1 For details of this cadmium-plating procedure and the necessary equipment refer to PMS<br />

Chapter 01-02-02 .<br />

(d) Cadmium Plating ('DALIC' Process) for steel with a maximum tensile strength of <strong>11</strong>00 N/mm ²<br />

(159 KSI).<br />

NOTE: Alternative procedures given in Paragraph 2.B.(1).(e) for steels and in Paragraph 2.B.(1).<br />

(f) for stainless steels.<br />

1 Materials and Equipment<br />

Contact AIRBUS to obtain the reference source for the 'DALIC' materials.<br />

NOTE: For the power supply you need a 'DALIC' rectifier. Dishes for the solutions must be<br />

made out of glass, polythene or porcelain material. For electrodes use 'DALIC' tampons<br />

which have to be prepared in accordance with the material manufacturer's instructions.<br />

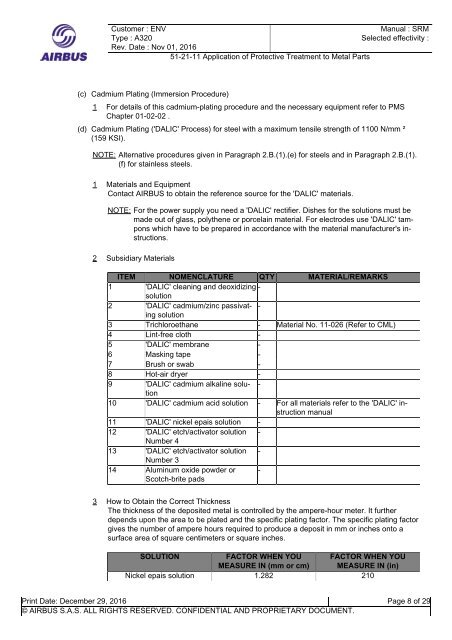

2 Subsidiary Materials<br />

ITEM NOMENCLATURE QTY MATERIAL/REMARKS<br />

1 'DALIC' cleaning and deoxidizing -<br />

solution<br />

2 'DALIC' cadmium/zinc passivating<br />

-<br />

solution<br />

3 Trichloroethane - Material No. <strong>11</strong>-026 (Refer to CML)<br />

4 Lint-free cloth -<br />

5 'DALIC' membrane -<br />

6 Masking tape -<br />

7 Brush or swab -<br />

8 Hot-air dryer -<br />

9 'DALIC' cadmium alkaline solution<br />

-<br />

10 'DALIC' cadmium acid solution - For all materials refer to the 'DALIC' instruction<br />

manual<br />

<strong>11</strong> 'DALIC' nickel epais solution -<br />

12 'DALIC' etch/activator solution -<br />

Number 4<br />

13 'DALIC' etch/activator solution -<br />

Number 3<br />

14 Aluminum oxide powder or<br />

Scotch-brite pads<br />

-<br />

3 How to Obtain the Correct Thickness<br />

The thickness of the deposited metal is controlled by the ampere-hour meter. It further<br />

depends upon the area to be plated and the specific plating factor. The specific plating factor<br />

gives the number of ampere hours required to produce a deposit in mm or inches onto a<br />

surface area of square centimeters or square inches.<br />

SOLUTION<br />

FAC<strong>TO</strong>R WHEN YOU FAC<strong>TO</strong>R WHEN YOU<br />

MEASURE IN (mm or cm) MEASURE IN (in)<br />

Nickel epais solution 1.282 <strong>21</strong>0<br />

Print Date: December 29, 2016 Page 8 of 29<br />

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.