REMKO RKW 1000 â 9800 INOX Stainless Steel Chiller Operation ...

REMKO RKW 1000 â 9800 INOX Stainless Steel Chiller Operation ...

REMKO RKW 1000 â 9800 INOX Stainless Steel Chiller Operation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ON/OFF/RESET Button<br />

ON/OFF<br />

RESET<br />

This button is used to switch the unit on and off. If the<br />

alarm has been set off and the unit has to be manually<br />

reset, this button is pressed to prevent further alarms<br />

from being acknowledged. At the same time, the normal<br />

operating function of the unit is restored.<br />

Alarm LED<br />

Alarm<br />

If this LED is lit up, the unit’s alarm has gone off and operation<br />

has been interrupted.<br />

SET Button<br />

SET<br />

The parameters settings can be changed by pressing<br />

the SET button together with the arrow keys.<br />

Compressor LED<br />

This LED is not lit up when the compressor is not in operation.<br />

If this LED is blinking, the compressor is currently<br />

in start-up time delay and will begin operation after<br />

this time has elapsed. If this LED is continuously lit<br />

up, the compressor is in operation. The time delay is no<br />

longer active.<br />

Line LED<br />

Fan Board<br />

Line<br />

Comp<br />

This LED is continuously lit up when the regulation is<br />

connected to the power supply.<br />

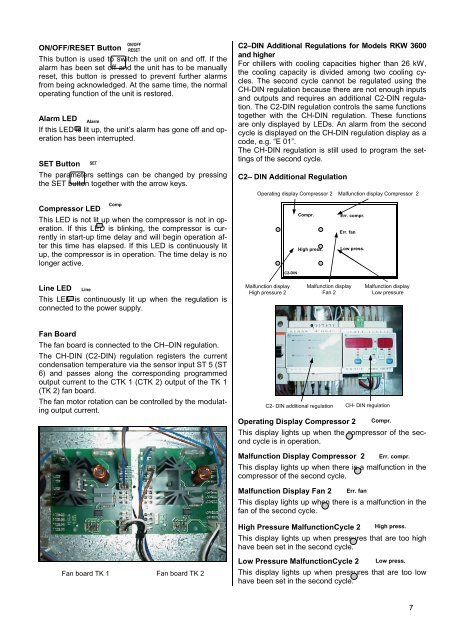

The fan board is connected to the CH–DIN regulation.<br />

The CH-DIN (C2-DIN) regulation registers the current<br />

condensation temperature via the sensor input ST 5 (ST<br />

6) and passes along the corresponding programmed<br />

output current to the CTK 1 (CTK 2) output of the TK 1<br />

(TK 2) fan board.<br />

The fan motor rotation can be controlled by the modulating<br />

output current.<br />

Fan board TK 1 Fan board TK 2<br />

C2–DIN Additional Regulations for Models <strong>RKW</strong> 3600<br />

and higher<br />

For chillers with cooling capacities higher than 26 kW,<br />

the cooling capacity is divided among two cooling cycles.<br />

The second cycle cannot be regulated using the<br />

CH-DIN regulation because there are not enough inputs<br />

and outputs and requires an additional C2-DIN regulation.<br />

The C2-DIN regulation controls the same functions<br />

together with the CH-DIN regulation. These functions<br />

are only displayed by LEDs. An alarm from the second<br />

cycle is displayed on the CH-DIN regulation display as a<br />

code, e.g. “E 01”.<br />

The CH-DIN regulation is still used to program the settings<br />

of the second cycle.<br />

C2– DIN Additional Regulation<br />

Operating display Compressor 2<br />

Malfunction display<br />

High pressure 2<br />

C2-DIN<br />

Compr.<br />

High press.<br />

C2- DIN additional regulation<br />

Operating Display Compressor 2<br />

Compr.<br />

This display lights up when the compressor of the second<br />

cycle is in operation.<br />

Malfunction Display Compressor 2<br />

Err. compr.<br />

This display lights up when there is a malfunction in the<br />

compressor of the second cycle.<br />

Malfunction Display Fan 2<br />

Err. fan<br />

Malfunction display<br />

Fan 2<br />

Err. compr.<br />

Low press.<br />

Err. fan<br />

This display lights up when there is a malfunction in the<br />

fan of the second cycle.<br />

High Pressure MalfunctionCycle 2<br />

High press.<br />

This display lights up when pressures that are too high<br />

have been set in the second cycle.<br />

Low Pressure MalfunctionCycle 2<br />

Malfunction display Compressor 2<br />

Malfunction display<br />

Low pressure<br />

CH- DIN regulation<br />

Low press.<br />

This display lights up when pressures that are too low<br />

have been set in the second cycle.<br />

7