ALR Tablet Presentation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

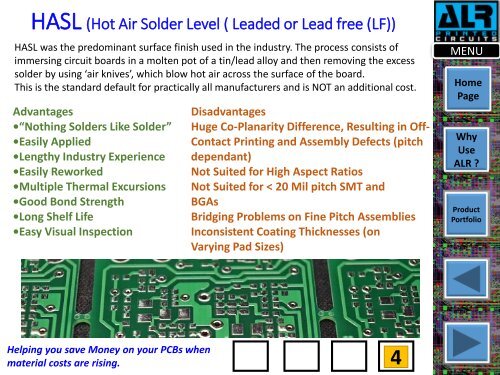

HASL (Hot Air Solder Level ( Leaded or Lead free (LF))<br />

HASL was the predominant surface finish used in the industry. The process consists of<br />

immersing circuit boards in a molten pot of a tin/lead alloy and then removing the excess<br />

solder by using ‘air knives’, which blow hot air across the surface of the board.<br />

This is the standard default for practically all manufacturers and is NOT an additional cost.<br />

Advantages<br />

•“Nothing Solders Like Solder”<br />

•Easily Applied<br />

•Lengthy Industry Experience<br />

•Easily Reworked<br />

•Multiple Thermal Excursions<br />

•Good Bond Strength<br />

•Long Shelf Life<br />

•Easy Visual Inspection<br />

Disadvantages<br />

Huge Co-Planarity Difference, Resulting in Off-<br />

Contact Printing and Assembly Defects (pitch<br />

dependant)<br />

Not Suited for High Aspect Ratios<br />

Not Suited for < 20 Mil pitch SMT and<br />

BGAs<br />

Bridging Problems on Fine Pitch Assemblies<br />

Inconsistent Coating Thicknesses (on<br />

Varying Pad Sizes)<br />

MENU<br />

Home<br />

Page<br />

Why<br />

Use<br />

<strong>ALR</strong> ?<br />

Product<br />

Portfolio<br />

Helping you save Money on your PCBs when<br />

material costs are rising.<br />

4