ALR Tablet Presentation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

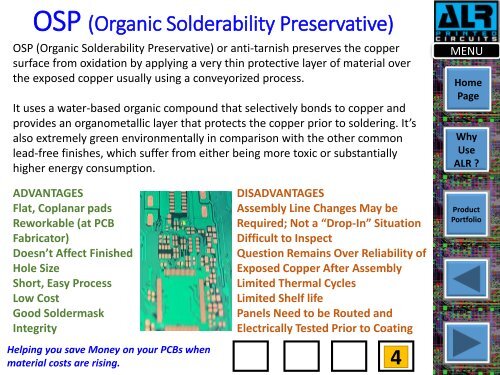

OSP (Organic Solderability Preservative)<br />

OSP (Organic Solderability Preservative) or anti-tarnish preserves the copper<br />

surface from oxidation by applying a very thin protective layer of material over<br />

the exposed copper usually using a conveyorized process.<br />

It uses a water-based organic compound that selectively bonds to copper and<br />

provides an organometallic layer that protects the copper prior to soldering. It’s<br />

also extremely green environmentally in comparison with the other common<br />

lead-free finishes, which suffer from either being more toxic or substantially<br />

higher energy consumption.<br />

MENU<br />

Home<br />

Page<br />

Why<br />

Use<br />

<strong>ALR</strong> ?<br />

ADVANTAGES<br />

Flat, Coplanar pads<br />

Reworkable (at PCB<br />

Fabricator)<br />

Doesn’t Affect Finished<br />

Hole Size<br />

Short, Easy Process<br />

Low Cost<br />

Good Soldermask<br />

Integrity<br />

Helping you save Money on your PCBs when<br />

material costs are rising.<br />

DISADVANTAGES<br />

Assembly Line Changes May be<br />

Required; Not a “Drop-In” Situation<br />

Difficult to Inspect<br />

Question Remains Over Reliability of<br />

Exposed Copper After Assembly<br />

Limited Thermal Cycles<br />

Limited Shelf life<br />

Panels Need to be Routed and<br />

Electrically Tested Prior to Coating<br />

4<br />

Product<br />

Portfolio