ATEX compliant - SMC

ATEX compliant - SMC

ATEX compliant - SMC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

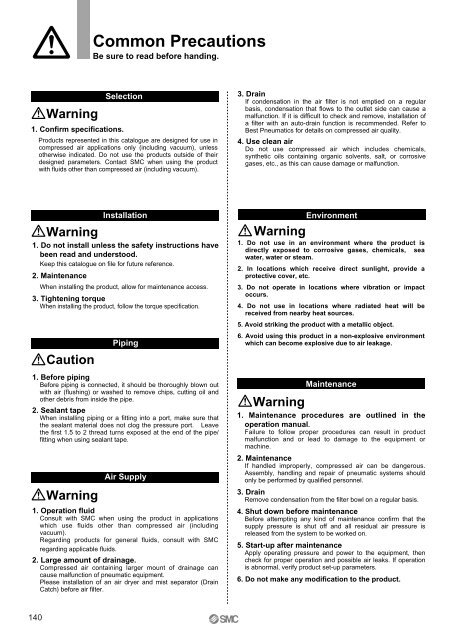

Warning<br />

1. Confirm specifications.<br />

Warning<br />

Caution<br />

Warning<br />

Common Precautions<br />

Be sure to read before handing.<br />

Selection<br />

Products represented in this catalogue are designed for use in<br />

compressed air applications only (including vacuum), unless<br />

otherwise indicated. Do not use the products outside of their<br />

designed parameters. Contact <strong>SMC</strong> when using the product<br />

with fluids other than compressed air (including vacuum).<br />

Installation<br />

1. Do not install unless the safety instructions have<br />

been read and understood.<br />

Keep this catalogue on file for future reference.<br />

2. Maintenance<br />

When installing the product, allow for maintenance access.<br />

3. Tightening torque<br />

When installing the product, follow the torque specification.<br />

Piping<br />

1. Before piping<br />

Before piping is connected, it should be thoroughly blown out<br />

with air (flushing) or washed to remove chips, cutting oil and<br />

other debris from inside the pipe.<br />

2. Sealant tape<br />

When installing piping or a fitting into a port, make sure that<br />

the sealant material does not clog the pressure port. Leave<br />

the first 1.5 to 2 thread turns exposed at the end of the pipe/<br />

fitting when using sealant tape.<br />

Air Supply<br />

1. Operation fluid<br />

Consult with <strong>SMC</strong> when using the product in applications<br />

which use fluids other than compressed air (including<br />

vacuum).<br />

Regarding products for general fluids, consult with <strong>SMC</strong><br />

regarding applicable fluids.<br />

2. Large amount of drainage.<br />

Compressed air containing larger mount of drainage can<br />

cause malfunction of pneumatic equipment.<br />

Please installation of an air dryer and mist separator (Drain<br />

Catch) before air filter.<br />

140<br />

3. Drain<br />

If condensation in the air filter is not emptied on a regular<br />

basis, condensation that flows to the outlet side can cause a<br />

malfunction. If it is difficult to check and remove, installation of<br />

a filter with an auto-drain function is recommended. Refer to<br />

Best Pneumatics for details on compressed air quality.<br />

4. Use clean air<br />

Do not use compressed air which includes chemicals,<br />

synthetic oils containing organic solvents, salt, or corrosive<br />

gases, etc., as this can cause damage or malfunction.<br />

Warning<br />

Warning<br />

Environment<br />

1. Do not use in an environment where the product is<br />

directly exposed to corrosive gases, chemicals, sea<br />

water, water or steam.<br />

2. In locations which receive direct sunlight, provide a<br />

protective cover, etc.<br />

3. Do not operate in locations where vibration or impact<br />

occurs.<br />

4. Do not use in locations where radiated heat will be<br />

received from nearby heat sources.<br />

5. Avoid striking the product with a metallic object.<br />

6. Avoid using this product in a non-explosive environment<br />

which can become explosive due to air leakage.<br />

Maintenance<br />

1. Maintenance procedures are outlined in the<br />

operation manual.<br />

Failure to follow proper procedures can result in product<br />

malfunction and or lead to damage to the equipment or<br />

machine.<br />

2. Maintenance<br />

If handled improperly, compressed air can be dangerous.<br />

Assembly, handling and repair of pneumatic systems should<br />

only be performed by qualified personnel.<br />

3. Drain<br />

Remove condensation from the filter bowl on a regular basis.<br />

4. Shut down before maintenance<br />

Before attempting any kind of maintenance confirm that the<br />

supply pressure is shut off and all residual air pressure is<br />

released from the system to be worked on.<br />

5. Start-up after maintenance<br />

Apply operating pressure and power to the equipment, then<br />

check for proper operation and possible air leaks. If operation<br />

is abnormal, verify product set-up parameters.<br />

6. Do not make any modification to the product.