You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TRANSOCEAN</strong> <strong>WINNER</strong>

GENERAL INFORMATION<br />

<strong>TRANSOCEAN</strong> - COMPANY PROFILE<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Transocean is a worldwide drilling company engaged in contract drilling of oil and gas<br />

wells. The Company specializes in technically demanding segments of the offshore<br />

drilling business, including deep water, harxh environment, turnkey and integrated<br />

drilling services.<br />

Transocean is a public company, headquartered in Houston, Texas, and the stock is<br />

traded on the New York Stcck Exchange.<br />

INTRODUCTION TO <strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

The Transocean Winner, ex Treasure Saga, is a semi-submersible drilling rig of the<br />

GVA 4000 design, built in 1983. Meets the special requirements by Norwegian Maritime<br />

Directorate and Norwegian Petroleum Directorate. The rig is classified by the Norske<br />

Veritas as +1A1 and complies to the regulations of the flagg state, the Norwegian<br />

Petroleum Directorate and UK Department of Energy and UK Health and Safety<br />

Executive.<br />

Transocean Winner can operate in water depth from 60 m to 460 m and is equipped<br />

with 15,000 psi well controll equippment.<br />

The particulars, performance data and equipment are described on the following pages.

GENERAL INFORMATION<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Unit Name : Transocean Winner<br />

Unit Owner and Operator : Transocean International / Transocean Offshore (North Sea) LTD<br />

Flag. Port of registry: Majuro, Republic of Marshall Islands.<br />

Unit classification : Det Norske Veritas Classification A/S . Maltese Cross 1A1-Column Stabilised Unit.<br />

Additional class notifications: CRANE, E0, HELDK<br />

Rated drilling depth : 7,620 m<br />

Maximum water depth : 460 m Minimum operating water depth: 60 m<br />

Rig design : GVA 4000<br />

Yard : Gøtaverken Arendal 1983<br />

Year placed in service : 1983<br />

Unit shape/unit design: 2+2 x columns x 2 pontoon supported semi- submersible of GVA 4000, design<br />

No of thrusters : 2 each of 2,400 kW azimuth thrusters<br />

Transit speed towed : 8 knots Transit speed thrusters: 6,5 knots<br />

Positioning system : Eight point anchor/chain system.<br />

Length Overall : 92.,92 m Width Overall: 78,84 m<br />

Depth keel to main deck : 42.30 m<br />

Draughts, : Drilling: 20.50 m Transit: 7.22 m (Exclusive thruser depth)<br />

Thruster depth below pontoons: 3,76 m<br />

Total operation variable load :3,556 tonnes<br />

Total survival variable load : 3,386 tonnes<br />

Total transit variable load : 2,508 tonnes<br />

Accommodation : Max 100 persons in 46 two-men cabins and 8 one-man cabins, fully air conditioned.<br />

Helideck designed for : Sikorski S61N or similar<br />

ENVIRONMENTAL CRITERIA FOR OPERATION<br />

ENVIRONMENTAL SURVIVAL CONDITIONS LIMITING OPERATION<br />

CONDITIONS<br />

CONDITION DRILLING<br />

Wind speed 61. 5 m/s 1 min sustained 33 m/s 10 min average<br />

Wave height (H max ) 35 m (H max ) 15.0 m<br />

Mean wave period 13-14 s 13-14 s<br />

Current speed 1.3 m/s 1.3 m/s<br />

Heave 4 m<br />

STORAGE CAPABILITIES AND MARINE EQUIPMENT<br />

Storage capacities<br />

Diesel oil 2,563 m 3<br />

Helicopter fuel 5 m 3<br />

Fuel consumption, transit 25 tonne/day<br />

Fuel consumption, drilling 18 tonne/day<br />

Drilling water 2,842 m 3<br />

Potable water 394 m 3<br />

Active liquid mud ( on deck) 73 m 3<br />

Reserve liquid mud (on deck) 261 m 3<br />

Bulk bentonite 122 m 3<br />

Bulk barite 334 m 3<br />

Bulk cement 218 m 3<br />

Sack storage 7,500 sacks<br />

Pipe racks area 600 m 2/ /1,500 mt<br />

Riser racks 171 m 2 /290 mt<br />

Miscellaneous storage area NA<br />

Base-oil-based storage 275 m 3 (In column)<br />

Brine storage 275 m 3 (In column)<br />

Rig power plant<br />

Complete power system comprising of diesel driven<br />

generator sets supplying DC and AC power.<br />

Diesel engine plant<br />

4 each diesel engines<br />

Make Nohab Diesel<br />

Type F312V<br />

Power each engine: 2,100 kW<br />

Total output, 8,400 kW .<br />

Equipped with spark arrestors and mufflers .<br />

Independent fuel supply to each engine and<br />

automatic engine shut down in case of 'racing'.<br />

Emergency generator<br />

One emergency generator set of 358 kW complete<br />

with its own switch board and wiring. The emergency<br />

system is completely independent of the main system<br />

and powers all emergency lightning and functions .<br />

Emergency Generator: MAN Diesel 487 hp with<br />

Stamford Genertator 437,5 KVA, 440 V AC<br />

AC - Generator<br />

Quantity : 4<br />

Make. : NEBB<br />

Type, : WAB 8000 H8F<br />

Output : 3,000 KVA, 6,000 V AC, 60 hz<br />

At rotation speed of RPM 900<br />

SCR system<br />

Number of SCRs : 9<br />

Make/Type : NEBB/THYITROL 02<br />

Maxi. cont. power kW : 9 x 960 kW<br />

Output Voltage : 720 V DC<br />

Transformer system<br />

Quantity : 2<br />

Make/Type : NEBB<br />

Input Voltage : 6,000 V<br />

Output Voltage : 600, 450 V<br />

Frequency : 60 Hz<br />

Quantity : 3<br />

Make/Type : NEBB<br />

Input Voltage : 450 V<br />

Output Voltage : 230, 208, 120 V<br />

Frequency : 60 Hz<br />

Quantity : 2<br />

Make/Type : NEBB

Input Voltage : 600 V<br />

Output Voltage : 205 V<br />

Frequency : 60 Hz<br />

Propulsion/thrusters<br />

Azimuth Thrusters : 2 each<br />

Type : KAMEWA RO-Thr. 2800<br />

Motors : NEBB QVW 710 HA8<br />

Output : 2,400 kW each thruster<br />

Positioning System<br />

Subsea Acoustic Transponder System<br />

Type: Honeywell RS 902<br />

Hole position/Riser Angle Indicator.<br />

Type: Konmap DGPS<br />

Mooring System<br />

8 point spread, 45 0 between the anchor lines<br />

4 double Norwinch Oilrig 2A-2-2-76 windlasses<br />

8 Anchors, type Steven 17 tonnes<br />

8 Anchor Chains, K4, 76 mm, 6010 kN breaking<br />

strength, 131,4 kg/m 1700 m each<br />

8 each permanent chain chasers w/ 200' 3" wire<br />

Telecommunication equipment<br />

• 'Inmarsat A' terminal for voice and telex with<br />

interface suitable for dial-up PC and facsimile<br />

transmission.<br />

• VHF-Am aeronautical radio equipment.<br />

Minimum output power 15 W. Frequency<br />

continuously selectable.<br />

• Aeronautical Non-Directional Beacon.<br />

Minimum output power 50 W.<br />

• All mandatory marine radio equipment such as<br />

GMDSS; HF, MF, VHF- etc.<br />

• Norsat B terminal with direct dialling to shore.<br />

• E-mail with Internet connection.<br />

Safety Equipment<br />

The unit is equipped with safety equipment according<br />

to IMO Code, UK Regulations and Norwegian Regs.<br />

Evacuation Systems<br />

Survival craft<br />

Make : Watercraft<br />

Quantity : 4<br />

Capacity persons/craft: 50. Total 200 persons<br />

Fire protected<br />

Rescue boat<br />

Make/type: Springer MP-741<br />

Weather limitations on launching :Wave height 2.5<br />

m. Wind 21 knots. Capacity 10 persons<br />

Life rafts<br />

Make/Type Viking KF<br />

Number on board 5<br />

Capacity each 20<br />

Firefigting Equipment<br />

The unit is equipped with fire fighting equipment<br />

according to IMO Code, UK Regulations and<br />

Norwegian Regulations.<br />

Fire and gas detection Equipment<br />

The unit is equipped with fire and gas detection<br />

equipment according to IMO Code, UK Regulations<br />

and Norwegian Regulations.<br />

DRILLING EQUIPMENT<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Revolving cranes<br />

2 each Liebherr BOS 50/1500 Electro Hydraulic<br />

offshore cranes.<br />

Max rated cap at 20 m reach : 50 metric tons<br />

Max rated cap at 40 m reach : 18 metric tons<br />

Cranes are fitted with instrumentation, safety devices<br />

and alarms according to UK and Norwegian regs.<br />

Pneumatic winches<br />

Make Atlas Copco<br />

Type OWK 213-55, 213-87, 805-67, MRK 64<br />

Capacity 4.6 tonnes<br />

Wire diameter in mm : 19<br />

No on drillfloor : 3,<br />

No on cellar deck : 4<br />

No on fingerboard, derrick : 1, Cap 0.5 mt<br />

No under catwalk : 1, Make GMC<br />

No on main deck : 2<br />

'Man-riding' winches<br />

1 man-riding winche on cellar deck<br />

1 man-riding winche ondrill floor<br />

Satisfies NPD requirement for man riding winches<br />

Auxiliary machinery<br />

2 each Water maker, Atlas JWP-26-C80/100<br />

3 each rig air compressors, Atlas Copco, GA 1210.<br />

Cap. of each: 17 Nm 3 /min at 8,6 bar pressure<br />

2 each bulk serv. compressors, Atlas Copco, GA 1407<br />

Cap. of each: 27 Nm 3 /min at 4,1 bar pressure<br />

2 each steam boilers:<br />

1 each Aalborg Verft AQ-3, Cap: 156 mt/day<br />

1 each Clayton E 304, Cap: 112 mt/day<br />

Derrick/mast<br />

Make/type : U.I.E Dynamic U.I.E SN 130,<br />

Dynamic, Galvanized steel<br />

Height : 48,70 m<br />

Width of base : 12 x 12 m<br />

Width of top : 5,49 x 5,49 m<br />

Nominal capacity : 570 mt<br />

Number of lines : 14<br />

Setback capacity : 300 mt<br />

Simultaneous setbackhookload<br />

capacity : 716 tonnes<br />

Racking platform<br />

Make/type : B.J. - Type 'V'<br />

Capacity of 5" DP: 7000 m/ 248 std<br />

Capacity of 8" DC : 14 stds<br />

Capacity of 9.5" DC: 14 stds<br />

1 each Pipe handling control cabins<br />

The racking system and pipe handling system in the<br />

derrick is remote controlled.<br />

Stabbing arm<br />

Make/type : MH HTV-arm & Moelven DF 210 arm.<br />

Drillpipe rack to drillfloor handling<br />

system<br />

Remote operated skid way, which delivers piping to<br />

the drillfloor and MH HTV Maskin. Cap. 3.5<br />

mt.Satisfies latest NPD requirement<br />

AUXILIARY EQUIPMENT<br />

Drawworks<br />

Make/type : National 1625 DE<br />

Last Update: 08..10.2003 Page 4 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc

Drum type : Lebus, Grooved<br />

Spinning cathead : National<br />

Breakout cathead : National<br />

Safety device make: Crown-O-Matic<br />

Sandline : Length 6248 m, Ø=14,3 mm,<br />

Breaking strength 24kN<br />

Input power : 2,031 kW<br />

Drum diameter : 915 mm<br />

Maximum line pull: 782 mt w/ 14 lines<br />

Maximum line pull: 689 mt w/ 12 lines<br />

Electric motors : 3 each<br />

E-motor make/mod: Nebb GNW 400 S33F<br />

Output power : 677 HP each<br />

Auxiliary brake<br />

Make/Model : Baylor Elmagco mod. 7838<br />

Back-up system : Battery pack.<br />

Kinetic Energy Monitoring system<br />

Make/type : Lidan Nor Floorsaver<br />

Crown block<br />

Make/type : Ref. C.M. Compensator<br />

Rated capacity : 590 mt<br />

No of sheaves : 7<br />

Sheave diameter : mm 1524<br />

Sheave grooved for : 38 mm line size<br />

Travelling block<br />

Make/type : National 760 H 650<br />

Rated capacity : 650 tons, 590 mt<br />

No of sheaves : 7, Ø= 1524 mm<br />

Hook (Not installed)<br />

Make/type : Maritime Hydraulic MH 975<br />

Rated capacity : 589 mt<br />

Drill string motion compensator (Crown<br />

Mounted)<br />

Make : NL Sheafer<br />

Type : CMC-600-25<br />

Stroke in m : 7.6 m<br />

Capacity - compensated : 272 mt<br />

Capacity - locked : 680 mt<br />

Rotary table<br />

Make/type : National 495C<br />

Maximum opening in mm : 1257,3<br />

Rated capacity in mt : 750<br />

Independent electric motor, two speed gearbox<br />

Electric motor type/make : Nebb GNW 400 S33F<br />

Output power in kW : 677<br />

Maximum continuous torque: 28,000 ft.lbs<br />

Master Bushings (split type)<br />

Make/Type : Varco MPCH<br />

Full range of inserts bowls to suit all contractor's<br />

tubulars and for running all standard casing sizes<br />

Top drive<br />

Make : Varco TDS-4H<br />

Type : Hi-Torque<br />

Rated capacity : 590 mt<br />

Test/working pressure in Bar: 345<br />

Remote operated kelly cock: 15,000 psi WP<br />

Electric Motor : 1<br />

Make : GE<br />

DRILLING EQUIPMENT<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Type : 752 H<br />

Output power in kW : 820<br />

Output torque in ft.lbs : 31,000 @ 135 rpm<br />

Gearbox, no of gears : 2<br />

Maximum rotary speed : 205 @ 22,000 ft.lbs<br />

Mudline diameter in inch : 3<br />

Drill pipe 5"<br />

Drill pipe, OD inch : 5<br />

Grade : S - 135<br />

Total length m :<br />

Range : 2<br />

Weight lbs/ft : 19,5<br />

Internally plastic coated<br />

Tool joint OD inch : 6 1/2<br />

Tool joint ID inch : 3 1/4<br />

Tapered shoulder tool joints : 18 0<br />

Type of connections : 4 1/2" IF<br />

Type of hardfacing : Arnco 100<br />

API classifications : Premium<br />

Drill pipe pup joints : 5” nominal size<br />

Quantity 8; 2 x 1.52 m, 2 x 3.04m, 2 x 4.57 m, 2 x 6,09m<br />

Drill pipe 3 1/2"<br />

Drill pipe, OD :<br />

Grade :<br />

Total length m :<br />

Range :<br />

Weight lbs/ft :<br />

Internally plastic coated<br />

Tool joint OD :<br />

Tool joint ID i :<br />

Tapered shoulder tj :<br />

Type of connections :<br />

Type of hardfacing :<br />

API classifications :<br />

Hevi-wate drill pipe<br />

5" OD x 50 lbs/ft, 4 1/2"IF connections<br />

Drill collars with<br />

Spiralled, W/recess for zip-elevator and slips.<br />

Stress relief pin groove and boreback on box.<br />

9 each 9 1/2" OD, 3" ID, 7 5/8" Reg Connections<br />

9 each 8" OD, 2 13/16" ID, 6 5/8" Reg Con.<br />

12 each 6 1/2" OD, 2 13/16" ID, 4 1/2" IF Con.<br />

Cross-over subs<br />

Enough cross-over subs to make up all drill and<br />

fishing string configurations.<br />

Handling tools<br />

Elevators and slips to handle all the Contractor<br />

tubulars. PS30/BX elevator to handle Contractor<br />

tubulars and Operator’s casing: 20” 13 3/8” 9 5/8”<br />

and 7”.<br />

Manual tongs to handle all Contractor's tubulars and<br />

standard casing strings.<br />

Iron roughneck<br />

Make : Maritime Hydraulic<br />

Type : 1898<br />

Range size : 3-1/2" thru 9-1/2"<br />

Max make up torque : 100,000 ft.lbs<br />

Last Update: 08..10.2003 Page 5 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc

Break out torque : 125,000 ft.lbs<br />

Remote controlled<br />

Fishing equipment<br />

Fishing equipment for all of the Contractor's<br />

downhole equipment.<br />

Diverter BOP<br />

Make : Reagan Offshore<br />

Model : KFDS<br />

Size inch : 10" x 24"<br />

WP bar : 13.8<br />

OD outlets 49-1/2" top & bottom of housing<br />

Insert packer size inch : 12"<br />

Diverter flowlines : 2 each<br />

OD of flowlines inch : 12<br />

BOP stack<br />

One Hydril 18 3/4" BOP stack, Working Pressure<br />

15,000 psi. Rated for H 2 S service containing:<br />

• Well head Connector, Vetco H4, 15,000 psi<br />

• Two double "Hydril" rams containing: Four ram<br />

type preventers with MPL, of which three<br />

preventers for drill pipe and one with single-piece<br />

shearing blind rams. Rated 15,000 psi<br />

• One Annular Preventer, Hydril GX, WP 10,000<br />

psi<br />

• Subsea accumulators: 6 x 35 gal bottles.<br />

• Acoustic control System, Type Cameron<br />

Pipe rams available<br />

Blind/shearing rams : 1 sets<br />

5" DP rams fixed : 2 sets<br />

2 sets HT<br />

3 1/2" DP rams fixed : 1 sets<br />

3 sets HT<br />

3 1/2" - 5" variable rams : 3 sets<br />

Lower marine riser package<br />

Hydraulic connector : Vetco H4,<br />

Connector, Size 18-3/4" : WP 10,000 psi<br />

Annular Preventer, Hydril GL, WP 5,000 psi<br />

Flex Joint Assy 18-3/4". Make: Vetco Uniflex<br />

8 x 11 gal accumulator bottles<br />

Choke and kill valves<br />

8 each, CIW DF failsafe. ID 2 9/16"<br />

WP 15,000 psi. Pressure assist closed.<br />

BOP stack handling system<br />

"Normar" Elevator type transporter for moving the<br />

BOP from storage position well centre position.<br />

Cap. 215 mt<br />

Base plate trolley. Cap. 60 mt<br />

The system is fitted with a mechanical stabilising<br />

device, stabilizing the BOP through the splash zone.<br />

Marine riser<br />

Make : Vetco<br />

Model : MR6C<br />

OD x ID,inch x inch : 21 x 20<br />

Length, m : 15.24<br />

Quantity, : 29 incl. (19 w/buoyancy)<br />

Pipe material : Grade RMW65V<br />

DRILLING EQUIPMENT<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Pup joints, 1x1.5m, 1x3m, 1x4.5m, 1x6m<br />

2 9/16" ID Kill and Choke lines, WP 15,000 psi,<br />

5" ID Booster line, WP 3000 psi<br />

Telescopic joint<br />

Two Vetco, type MR-6C, 16 m stroke telescoping<br />

joint, support ring for tensioning lines and 2 9/16”<br />

bore kill and choke hoses, and booster line with WP<br />

corresponding to BOP.<br />

Buoyancy modules<br />

Make: Albany.<br />

Quantity: For dressing of 19 jts.<br />

BOP control System<br />

Koomey Hydraulic Control System, type 80, with pilot<br />

controlled subsea valves, electric/pneumatic<br />

powerpack, 113 x 11 gall bottles, 12 x 35 gal bottles<br />

total capacity 6,295 litres surface accumulators.<br />

2 remote control stations and complete emergency<br />

electric and pneumatic power back-up of all control<br />

functions<br />

Acoustic emergency BOP control system<br />

An acoustic emergency control system , type<br />

Cameron, with six functions to be used in the event<br />

the BOP functions are inoperable due to a failure of<br />

the hydraulic control system<br />

Description of functions Controls: LMRP Connector,<br />

2 Pipe Rams, Shear Rams, Ram locks.<br />

Choke manifold<br />

Vetco HT/HP choke manifold, rated to 15,000 psi,<br />

with two remote operated chokes and 1 manually<br />

operate choke. and 1 fixed choke. The choke<br />

manifold is rated for H 2 S service<br />

Riser tensioners<br />

One marine riser tensioning system of 4 double tensioners<br />

c/w control panel, air receivers, sheaves and<br />

wireline to give a line travel of 15 m. The system is<br />

independent, having its own electrically powered compressors<br />

and chemical or refrigeration air drying unit.<br />

4 each double NL Shaffer , Capacity each, kN<br />

354,900 (36 mt), Maximum stroke, m 3.81<br />

Wireline size inch, 1-3/4<br />

Guideline and Podline system<br />

Guideline tensioning system complete with control<br />

panel, air receivers, sheaves and 3/4" wirelines to give<br />

a total of 12 m line travel, having a capacity of 4 ton<br />

each with line storage drums behind tensioners.<br />

4 + 4 each, NL Shaffer, Capacity each 7.2 mt<br />

Air winches: Atlas Copco OWK 213-87, 700 m drum<br />

capacity.<br />

Mud pumps<br />

3 each mud pumps of 5000 psi WP.<br />

Make: Natuional<br />

Type: 12-P-160<br />

Each pump driven by 2 x Nebb motors. Each pump<br />

rated to 2 x 800 kW continuous service.<br />

The mud pumps are fed by 3 each supercharge<br />

pumps, each of 75 kW.<br />

Last Update: 08..10.2003 Page 6 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc

Mud storage capacity<br />

5 mud tanks on deck, totalling 334 m 3 or 2,100 bbls<br />

All tanks equipped with Brandt agitators of 25 or 10<br />

hp. In additionsolid handling tanks contain 50 m 3 or<br />

315 bbls.<br />

274 m 3 of brine can be stored in column tanks.<br />

274 m 3 of base oil can be stored in column tanks.<br />

Mud mixing system<br />

3 ea mud mixing pumps, 75 kW each<br />

2 ea mud hoppers, Make Pioner, SW 80064 Venture<br />

AMEC Automatic Mud System for high rate mixing of<br />

barite.<br />

Procon Automatic Sack handling and mud mixing.<br />

DRILLING EQUIPMENT<br />

Mud treatment system<br />

4 each Thule VMS 100 Shale Shakers, each with a<br />

flowrate of 4.8 m 3 /min. One equipped with<br />

desilterand acting as mud cleaner.<br />

2 each Thule Type VSM 200 Desilter System. Cap.<br />

180 m 3 /h.<br />

1 each pill/slug tank of 7.5 m 3<br />

1 each chemical mix tank of 7.5 m 3<br />

1 each Welco 5200 Degasser. Cap. 228 m 3 /h<br />

1 ea mud/gas separator designed according to DEN Safety<br />

Notice 11/90 with a 10" nom diam vent line to top of derrick<br />

Cementing system<br />

(Owned by cement contractor)<br />

Haliburton SKD-4 diesel powered cementing unit for<br />

15,000 psi service. The diesels located in separate<br />

sound isolated room<br />

X-Mas Tree Handling<br />

Quantity: 1 Trolley / 2 Skidding Plates<br />

Make: Westcon<br />

Type: Hydraulic Skidding / Sliding<br />

Rated Cap 60 ton<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

Last Update: 08..10.2003 Page 7 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc

DRILLING EQUIPMENT<br />

DERRICK HEIGHT INTERFACE REQUIREMENTS<br />

0,25<br />

48,38<br />

3,73<br />

TOP DRIVE (Make) : VARCO<br />

TOP DRIVE (Type) : TDS 4<br />

All length in meter.<br />

CLEARANCE<br />

DIM "A"<br />

ROTARY HOSE<br />

CONNECTION<br />

21,0<br />

SERVICE LOOP<br />

BRACKET<br />

1,2<br />

23,5<br />

8,35<br />

STAND<br />

28,5<br />

10,83<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

BLOCK<br />

Last Update: 08..10.2003 Page 8 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc<br />

HOOK<br />

SWIVE<br />

2,83<br />

0,72<br />

2,37<br />

4,91<br />

DIM "A"<br />

10,83

DRILLING EQUIPMENT<br />

RIG COMPONENT HOISTING CHARACTERISTICS<br />

MAX. LOAD CONSIDERING MAX. N° of LINES INSTALLED<br />

2<br />

1<br />

10<br />

8<br />

9<br />

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

ITEM DESCRIPTION STATIC CAPACITY Remarks<br />

1<br />

DERRICK Gross nominal capacity (mt.) 570<br />

Hook load capacity (mt.) 570<br />

2<br />

3<br />

4<br />

5<br />

5 a<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

With max. number of lines (nr.) 14<br />

CROWN BLOCK Rated load capacity (mt.) 590<br />

TRAVELLING BLOCK Rated load capacity (mt.) 588<br />

HOOK BLOCK Rated load capacity (mt.) NA<br />

SWIVEL HEAD Rated load capacity (mt.) 588<br />

TOP DRIVE Rated load capacity (mt.) 588<br />

RAKING PLATFORM Rated load capacity (DP, DC) 7,000 m of DP +<br />

14 stds DC<br />

RIG FLOOR SET BACK Rated load capacity (mt.) 220 Set Back + Hook Load<br />

= 540 mt<br />

ROTARY CASING CAPACITY Rated load capacity(mt.) 750<br />

DRAWWORK: main drum Rated load capacity (mt.) 454<br />

DRILLING LINE Rated load capacity (mt.) 38<br />

DEAD LINE ANCHOR Rated load capacity (mt.) 46<br />

Max. load that rig can handle (mt.) 454<br />

Due to the weakest equipment (to be specified) Drawwork<br />

Last Update: 08..10.2003 Page 9 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc<br />

6<br />

3<br />

4<br />

5<br />

5a<br />

11<br />

7

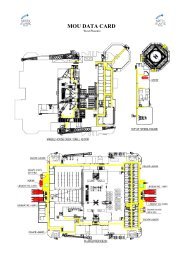

108683<br />

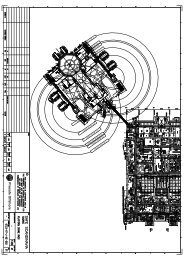

<strong>TRANSOCEAN</strong> <strong>WINNER</strong><br />

TONSBERG<br />

<strong>WINNER</strong><br />

PROFILE<br />

0m 10m 20m<br />

80520<br />

<strong>TRANSOCEAN</strong><br />

Last Update: 08..10.2003 Page 10 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc<br />

34200<br />

67483<br />

41200

*<br />

U<br />

<strong>WINNER</strong><br />

PLAN VIEW<br />

0 5<br />

10<br />

15 20<br />

25<br />

40<br />

45<br />

55 60<br />

65<br />

70<br />

75<br />

80<br />

85<br />

90<br />

95<br />

CATWALK RISING FROM 2600 TO 6000 AB MAIN DECK<br />

WELL LOG<br />

TOOL HOUSE<br />

2600 AB.<br />

MAIN DECK<br />

D<br />

D<br />

CHOKE & KILL<br />

MANIFOLD<br />

U U<br />

DRILLFLOOR<br />

6000 AB MAIN DECK<br />

SET BACK<br />

AREA<br />

SMACCC<br />

HOSE REEL<br />

SKIDDING ROOF<br />

ROTARY<br />

SKIDDING ROOF<br />

SET BACK<br />

AREA<br />

DRILLERS<br />

HOUSE<br />

DRAWWORKS<br />

D<br />

HEAVY TOOL<br />

STORE<br />

0m 10m 20m<br />

66880<br />

<strong>TRANSOCEAN</strong><br />

Last Update: 08..10.2003 Page 11 of 11 Printed: 09.10.03<br />

\\SRVFILE01SVG\PROSJEKT$\420002\TM\Marketing\ShortSpecs\Winner.doc<br />

D<br />

U<br />

U<br />

W IN N E R<br />

N<br />

ROOF<br />

SHALE SHAKER<br />

ROOM<br />

6000 AB. MAIN DECK<br />

MUD LOGGING<br />

UNIT<br />

09t<br />

C E A<br />

D<br />

O<br />

SMACCC<br />

UNIT<br />

HELI CONTROL<br />

TOWER<br />

D<br />

T R A N S<br />

T R A N S<br />

D<br />

O<br />

NAVAL<br />

HOUSE TOP<br />

U<br />

C E A<br />

09t<br />

N<br />

W IN N E R<br />

100 105<br />

58220