You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

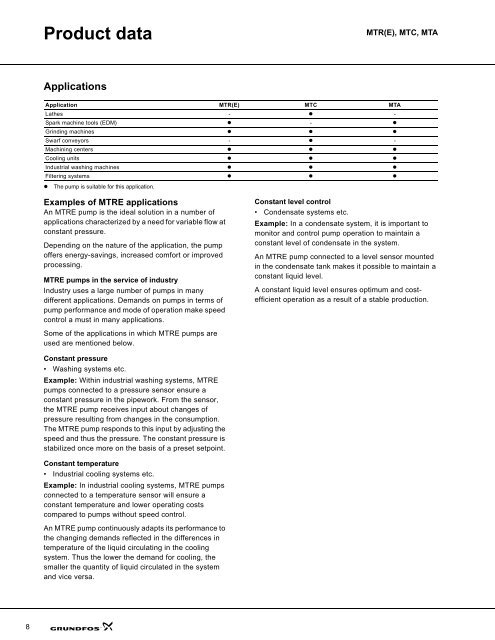

Product data<br />

Applications<br />

� The pump is suitable for this application.<br />

Examples of <strong>MTR</strong>E applications<br />

An <strong>MTR</strong>E pump is the ideal solution in a number of<br />

applications characterized by a need for variable flow at<br />

constant pressure.<br />

Depending on the nature of the application, the pump<br />

offers energy-savings, increased comfort or improved<br />

processing.<br />

<strong>MTR</strong>E pumps in the service of industry<br />

Industry uses a large number of pumps in many<br />

different applications. Demands on pumps in terms of<br />

pump performance and mode of operation make speed<br />

control a must in many applications.<br />

Some of the applications in which <strong>MTR</strong>E pumps are<br />

used are mentioned below.<br />

Constant pressure<br />

• Washing systems etc.<br />

Example: Within industrial washing systems, <strong>MTR</strong>E<br />

pumps connected to a pressure sensor ensure a<br />

constant pressure in the pipework. From the sensor,<br />

the <strong>MTR</strong>E pump receives input about changes of<br />

pressure resulting from changes in the consumption.<br />

The <strong>MTR</strong>E pump responds to this input by adjusting the<br />

speed and thus the pressure. The constant pressure is<br />

stabilized once more on the basis of a preset setpoint.<br />

Constant temperature<br />

• Industrial cooling systems etc.<br />

Example: In industrial cooling systems, <strong>MTR</strong>E pumps<br />

connected to a temperature sensor will ensure a<br />

constant temperature and lower operating costs<br />

compared to pumps without speed control.<br />

An <strong>MTR</strong>E pump continuously adapts its performance to<br />

the changing demands reflected in the differences in<br />

temperature of the liquid circulating in the cooling<br />

system. Thus the lower the demand for cooling, the<br />

smaller the quantity of liquid circulated in the system<br />

and vice versa.<br />

<strong>MTR</strong>(E), <strong>MTC</strong>, <strong>MTA</strong><br />

Application <strong>MTR</strong>(E) <strong>MTC</strong> <strong>MTA</strong><br />

Lathes - � -<br />

Spark machine tools (EDM) � - �<br />

Grinding machines � � �<br />

Swarf conveyors - � -<br />

Machining centers � � �<br />

Cooling units � � �<br />

Industrial washing machines � � �<br />

Filtering systems � � �<br />

Constant level control<br />

• Condensate systems etc.<br />

Example: In a condensate system, it is important to<br />

monitor and control pump operation to maintain a<br />

constant level of condensate in the system.<br />

An <strong>MTR</strong>E pump connected to a level sensor mounted<br />

in the condensate tank makes it possible to maintain a<br />

constant liquid level.<br />

A constant liquid level ensures optimum and costefficient<br />

operation as a result of a stable production.