Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

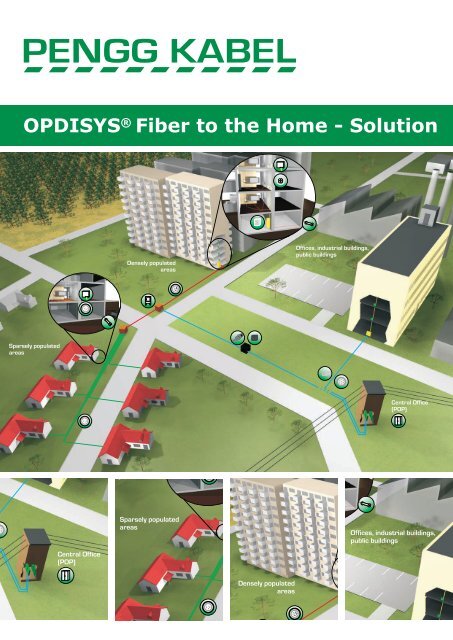

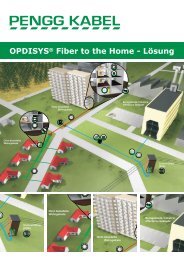

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution

Optical distribution system<br />

OPDISYS ® -rack<br />

The OPDISYS ® -rack was specially designed for Fiber-To-The-Home (FTTH) applications. It is a modular system consisting of a basic rack, cable<br />

management, mandrel extension racks and gasblocker extension racks and <strong>fiber</strong> modules. Thanks <strong>to</strong> its design this system is very flexible. The<br />

extension racks can be ordered and combined individually according <strong>to</strong> <strong>the</strong> cus<strong>to</strong>mer´s needs. Each <strong>fiber</strong> module has a front plate with two<br />

types of uniform cut-out patterns in<strong>to</strong> which snap-in angled holders fitting in<strong>to</strong> <strong>the</strong> required adapter type can be inserted. This snap-in angled<br />

holder also ensures a 45 degree angle of <strong>the</strong> adapter is maintained. Each <strong>fiber</strong> module can be used as a left-side as well as a right-side <strong>fiber</strong><br />

module.<br />

By default, <strong>the</strong>re are protection tubes from <strong>the</strong> cable clamp <strong>to</strong> each individual module is installed by kink-resistant PBT-tubes. They ensure that<br />

<strong>the</strong> minimum curve radius of <strong>the</strong> cable loose tubes from <strong>the</strong> cable entry <strong>to</strong> <strong>the</strong> <strong>fiber</strong> modules will not be exceeded.<br />

The cable clamps are pre-installed ei<strong>the</strong>r on <strong>the</strong> <strong>to</strong>p or on <strong>the</strong> bot<strong>to</strong>m of <strong>the</strong> rack and are used <strong>to</strong> secure <strong>the</strong> strain relief of <strong>the</strong> incoming cables.<br />

They serve fur<strong>the</strong>r as a fixing point for <strong>the</strong> cable tubes. Optionally, <strong>the</strong> strain relief element of <strong>the</strong> incoming cable <strong>to</strong> be attached.<br />

Technical data:<br />

• maximum <strong>fiber</strong> density: 960 <strong>fiber</strong>s at SC,<br />

1920 <strong>fiber</strong>s at LC and E2000<br />

• comfortable patching with two-sided overlength<br />

patchcord s<strong>to</strong>rage<br />

• optional extensions (for cable guidance and<br />

gasblocker integration)<br />

• available as open and closed rack version<br />

• removable and rotatable splice/patch <strong>fiber</strong><br />

module<br />

• <strong>fiber</strong> module frontplate with different cu<strong>to</strong>uts<br />

and adapter mounting through snap-in<br />

angled holder available: SC, LC, E2000<br />

(o<strong>the</strong>rs on request)<br />

• optional integration of gas-blockers on<br />

incoming tubes possible (on request)<br />

• colour:<br />

RAL 7035, light grey<br />

• material: Powder coated steel<br />

• flammability: UL 94V-0<br />

The OPDISYS ® -rack is <strong>the</strong> core component of every OPDISYS ® -system. Both, an open version as well as a closed version, are available. An<br />

open version rack is turned in<strong>to</strong> a closed version rack by installing side panels and doors. The rack accommodates <strong>the</strong> <strong>fiber</strong> module carrier, <strong>the</strong><br />

cable entry plates, all types of extension modules and, if a closed version is required, <strong>the</strong> side panels as well as <strong>the</strong> front doors.<br />

Various fixing sets (see information in <strong>the</strong> accessories section of this document) are available which allow you <strong>to</strong> mount <strong>the</strong> rack <strong>to</strong> ei<strong>the</strong>r wall or<br />

ceiling or floor. It is possible <strong>to</strong> mount several racks next <strong>to</strong> each o<strong>the</strong>r back-<strong>to</strong>-back (requires only floor mounting) or next <strong>to</strong> each o<strong>the</strong>r (requires<br />

mounting both <strong>to</strong> floor and ceiling or wall for stability reasons). A stand-alone Single Row Rack should always be fixed <strong>to</strong> both floor and ceiling<br />

or wall.

Rack features:<br />

• <strong>to</strong>p or bot<strong>to</strong>m cable entry possible<br />

• <strong>to</strong>p cover provides openings for cables (optionally with brushes)<br />

• easy expansion with side-by-side or back-<strong>to</strong>-back mounting of racks<br />

• <strong>solution</strong>s for cross-connect and interconnect configurations<br />

• backside vertical cable guidance for incoming cables<br />

• bending radius protection of 30mm for <strong>fiber</strong>s and patchcords<br />

• intelligent patchcord management<br />

• vertical patchcord cable guidance on left and right side<br />

• mandrels on left and right side of <strong>the</strong> rack provide sufficient space for patchcord overlength s<strong>to</strong>rage<br />

• integrated patchcord management <strong>to</strong> adjacent racks avoids <strong>the</strong> usage of external ducts<br />

Dimensions & capacity -<br />

standard version (incl. mandrels)<br />

Rack height<br />

Rack width<br />

Rack weight (open / closed)<br />

Max. amount of modules<br />

Max. amount of terminations<br />

OPDISYS ® -rack 1000/40HU<br />

incl. mandrels, protective tubes<br />

OPDISYS ® -rack 1000/40HU<br />

2200 mm<br />

1000 mm<br />

118 kg / 170 kg<br />

80 Full-Size or 160 Half-Size<br />

960 SC<br />

1920 LC / E2000<br />

Art. No. 2735153<br />

OPDISYS ® -rack - possible extensions (on request)<br />

Gasblocker - extension rack<br />

When using blow-in systems, gasblockers are essential in order <strong>to</strong> protect <strong>the</strong> installation against gas<br />

and/or water entry. The gasblocker extension rack can accommodate <strong>the</strong> gasblockers. It has a built-in<br />

back panel, so no extra back panel is needed in order <strong>to</strong> turn it in<strong>to</strong> a closed version.<br />

Rack doors, side and back panels<br />

If a closed rack version is required, doors and panels can be attached <strong>to</strong> rack. Each door has an opening<br />

angle of 180°. The doors are equipped with an integrated lever and lock and have an A4 document holder<br />

on <strong>the</strong>ir inner side. Each side panel is useable for right as well as for left side mounting.<br />

Gasblocker - extension rack<br />

on request<br />

Panels / door set Art. No. 2735154<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

3

OPDISYS ® -rack - accessories<br />

Fixing sets<br />

Several fixing sets are available <strong>to</strong> mount <strong>the</strong> rack <strong>to</strong> <strong>the</strong> wall, on <strong>the</strong> floor or <strong>to</strong> mount multiple racks side<br />

by side or back <strong>to</strong> back <strong>to</strong> each o<strong>the</strong>r. Each individual fixing set contains all necessary screws, mounting<br />

brackets, washers and anchor pins.<br />

Tool kit<br />

• adapter holder pincer<br />

The adapter holder pincer is designed <strong>to</strong> easily remove <strong>the</strong> snap-in angled holder from <strong>the</strong> frontplate<br />

cu<strong>to</strong>ut of <strong>the</strong> OPDISYS ® <strong>fiber</strong> module. Thanks <strong>to</strong> its small and compact design it ensures <strong>the</strong> smooth<br />

removal of a snap-in angled holder without interfering with o<strong>the</strong>r connections.<br />

• <strong>to</strong>rx socket wrench<br />

• draw wire or element<br />

The draw wire or element <strong>to</strong>ol is necessary <strong>to</strong> insert <strong>the</strong> incoming <strong>fiber</strong> cable in<strong>to</strong> <strong>the</strong> <strong>fiber</strong> protection<br />

tube which is fed up <strong>to</strong> <strong>the</strong> <strong>fiber</strong> optic module. This <strong>to</strong>ol is required <strong>to</strong> install a OPDISYS ® -System.<br />

Fixing set, back-<strong>to</strong>-back or side-<strong>to</strong>-side Art. No. 2735155<br />

Fixing set for double bot<strong>to</strong>ms Art. No. 2735156<br />

Fixing set “base with leveling feet“ Art. No. 2735157<br />

Tool kit Art. No. 2735158<br />

OPDISYS ® -<strong>fiber</strong> modules<br />

The multi-circuit management <strong>fiber</strong> modules are used as combined splice & patch<br />

modules. They offer highest <strong>fiber</strong> density along with best maintainability. Maximum flexibility<br />

is guaranteed by metal frontplates and 45° angled adapter holders for all conventional<br />

adapter types. The <strong>fiber</strong> modules are available as full-size <strong>fiber</strong> modules with a height of<br />

1HU.<br />

Fiber modules can be equipped with different adapter types or with a closed frontplate<br />

without adapters for a splice-through version (in this case, a loop- back connection of<br />

<strong>fiber</strong>s can be done via splices).<br />

The material of <strong>the</strong> LSZH <strong>fiber</strong> modules is a Polycarbonate / ABS blend. The symmetrical<br />

design of <strong>the</strong> multi-circuit management <strong>fiber</strong> modules allows you <strong>to</strong> use <strong>the</strong> same module<br />

for left- and right-side mounting. A uniform module colour optimizes s<strong>to</strong>ck keeping, while<br />

individual threefold colour code labelling (on front, side and cover) provides fast and clear<br />

module and <strong>fiber</strong> identification. On request we can deliver each <strong>fiber</strong> module with a<br />

cus<strong>to</strong>mized labelling of <strong>the</strong> <strong>to</strong>p cover (index of all ports with description) as well as a<br />

labelling of <strong>the</strong> side of each Fiber Module (indication of <strong>the</strong> street and <strong>the</strong> building this<br />

module is assigned <strong>to</strong>) according <strong>to</strong> <strong>the</strong> cus<strong>to</strong>mer’s request. Also <strong>the</strong> labelling of <strong>the</strong> <strong>fiber</strong><br />

module numbering can be done by us.<br />

• <strong>fiber</strong> modules can be rotated by 90° and are removable from <strong>the</strong> rack<br />

• incoming <strong>fiber</strong>s and pigtails are s<strong>to</strong>red in separate areas<br />

• easy <strong>to</strong> snap in adapter holders allow comfortable cleaning of pigtail-connec<strong>to</strong>r<br />

ferrules by taking off <strong>the</strong> adapter holders.<br />

• identical splice protection holder for both shrink and crimp splice protection<br />

• two-sided, easy <strong>to</strong> remove transparent covers per <strong>fiber</strong> module<br />

• bending radius protection for all <strong>fiber</strong>s and pigtails<br />

• overlength s<strong>to</strong>rage of incoming cable subtube is possible on <strong>the</strong> bot<strong>to</strong>m side of <strong>the</strong><br />

module<br />

Technical Data:<br />

• Colour<br />

RAL 7035, light grey<br />

• Material<br />

Powder coated steel<br />

• Flammability UL 94V-0<br />

• Weight (full size module) 145 grams (without adapters and pigtails)<br />

Each Fiber Module is equipped with a frontplate, snap-in angled holders, rubber shrink/crimp splice protection holder, <strong>fiber</strong> protection pipe<br />

holder, two transparent covers, designation label, door latch and inserted adapters and pigtails.

Plug-in configuration - fully equipped<br />

SC LC E2000<br />

Amount of adapters 12 12 12<br />

Amount of pigtails 12 24 24<br />

Max. amount of spices<br />

Heat shrink splice protection*<br />

Crimp splice protection*<br />

Max. amount of spices 32 48<br />

* Heat shrink splice protection or crimp splice protection are not included and must be ordered separately.<br />

Fiber module 24 LC/APC, 1HU Art. No. 2535159<br />

Fiber module 24 E2000/APC, 1HU Art. No. 2535160<br />

Fiber module 12 SC/APC, 1HU Art. No. 2535161<br />

Fiber module for up <strong>to</strong> 48 splices, 1HU Art. No. 2535162<br />

Cable clamp set Art. No. 2735163<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

5

Patch cable<br />

PC LC/APC simplex, 2 mm<br />

Characteristics of LC/APC simplex:<br />

• user-friendly audible latch <strong>to</strong> indicate proper mating<br />

• push-pull locking<br />

• plastic housing with zirconia ferrule<br />

• standard IEC 61754-20<br />

• insertion loss (IL) for SM (typical)<br />

average value<br />

Fiber optic cable<br />

A-DQ(BN)2Y CT - Outdoor cable, center unitube, D35-S15<br />

outdoor cable<br />

rodent protection<br />

metal-free<br />

longitudinally<br />

water-tight<br />

A-DQ(BN)2Y CT 12E9/125 Art. No. 2035132<br />

A-DQ(BN)2Y CT 24E9/125 Art. No. 2035133<br />

Type number of numbers of tube-Ø tenisle strength outer-Ø weight<br />

<strong>fiber</strong>s / tube <strong>fiber</strong>s approx. mm max. N approx. mm approx. kg/km<br />

A-DQ(BN)2Y CT 12E9/125 12 12 3,5 2000 8,5 72,8<br />

A-DQ(BN)2Y CT 24E9/125 24 24 3,5 2000 8,5 73,7<br />

Central loose tube cable for outdoor applications. Rodent protected by glass rovings.<br />

This cable is used as low <strong>fiber</strong> count data cable in distribution networks and meets <strong>the</strong> demands of outdoor environments. Fibers according<br />

ITU-T G.652.D<br />

Construction<br />

center unitube<br />

strength members (aramide yarns)<br />

PE-sheath, UV-resistant, black with two orange longitudinal stripes<br />

Fiber colours<br />

1-12: red, green, yellow, blue, white, violet, orange, black, grey, brown, pink, turquoise<br />

13-24: red, green, yellow, blue, white, violet, orange, transparent, grey, brown, pink, turquoise -each with black rings every 50 mm (max.)<br />

Tube colour<br />

red<br />

Laying<br />

usable for fixed laying in ducts or conduits and outdoors<br />

Marking<br />

double-sinus, phone-sign, meter marking, PENGG KABEL, year of manufacturing<br />

Technical Data<br />

tensile strength:<br />

compressive strength:<br />

impact strength:<br />

<strong>to</strong>rsion:<br />

kink, cable:<br />

kink, tube:<br />

min. bending radius:<br />

temperature range:<br />

water penetration:<br />

according <strong>to</strong> IEC 60794-1-E1<br />

according <strong>to</strong> IEC 60794-1-E3 | value: 3000 N/10 cm<br />

according <strong>to</strong> IEC 60794-1-E4 | value: 5 Nm<br />

according <strong>to</strong> IEC 60794-1-E7 | value: 5 cycles ±1 turn<br />

according <strong>to</strong> IEC 60794-1-E10 | value: The cables do not form a kink when a loop is drawn <strong>to</strong>ge<strong>the</strong>r <strong>to</strong> a diameter<br />

of 100 mm.<br />

according <strong>to</strong> IEC 60794-1-E16 | value: The loose tubes do not kink.<br />

according <strong>to</strong> IEC 60794-1-E11 | value: R = 20 x D (cable outer diameter)<br />

according <strong>to</strong> IEC 60794-1-F1<br />

s<strong>to</strong>rage and transport: -40°C up <strong>to</strong> +70°C<br />

laying:<br />

-5°C up <strong>to</strong> +60°C<br />

operation:<br />

-25°C up <strong>to</strong> +70°C<br />

according <strong>to</strong> IEC 60794-1-F5 | value: No water on free end.<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

7

A-DQ(BN)2Y GGT - Outdoor cable, loose tube construction, D23-S20<br />

outdoor cable<br />

rodent protection<br />

metal-free<br />

longitudinally<br />

water-tight<br />

A-DQ(BN)2Y GGT 2x12E9/125 Art. No. 2035134<br />

A-DQ(BN)2Y GGT 4x12E9/125 Art. No. 2035135<br />

A-DQ(BN)2Y GGT 6x12E9/125 Art. No. 2035136<br />

A-DQ(BN)2Y GGT 8x12E9/125 Art. No. 2035137<br />

A-DQ(BN)2Y GGT 10x12E9/125 Art. No. 2035138<br />

A-DQ(BN)2Y GGT 12x12E9/125 Art. No. 2035139<br />

A-DQ(BN)2Y GGT 8x24 E9/125 Art. No. 2035140<br />

A-DQ(BN)2Y GGT 18x24E9/125 Art. No. 2035141<br />

Type number of number of tubes number of tube-Ø tensile strength outer-Ø weight<br />

<strong>fiber</strong>s/tube + fillers <strong>fiber</strong>s approx. mm max. N approx. mm approx. kg/km<br />

A-DQ(BN)2Y GGT 2x12E9/125 12 2 + 3 24 2,3 3500 13,2 141,7<br />

A-DQ(BN)2Y GGT 4x12E9/125 12 4 + 1 48 2,3 3500 13,2 145,3<br />

A-DQ(BN)2Y GGT 6x12E9/125 12 6 + 0 72 2,3 3500 13,5 160,0<br />

A-DQ(BN)2Y GGT 8x12E9/125 12 8 + 0 96 2,3 3500 14,8 182,5<br />

A-DQ(BN)2Y GGT 10x12E9/125 12 10 + 0 120 2,3 3500 16,3 214,0<br />

A-DQ(BN)2Y GGT 12x12E9/125 12 12 + 0 144 2,3 3500 18,0 251,0<br />

A-DQ(BN)2Y GGT 8x24E9/125 24 8 + 0 192 2,3 3500 16,5 221,8<br />

A-DQ(BN)2Y GGT 18x24E9/125 24 18 + 0 432 2,3 3500 20,5 335,4<br />

Stranded loose tube cable for outdoor applications. Highly rodent protected by 2 layers of glass rovings.<br />

This cable is used as higher <strong>fiber</strong> count data cable in distribution networks and withstands environments with high mechanical demands.<br />

Fibers according ITU-T G.652.D<br />

Construction<br />

FRP-central element<br />

loose tubes, SZ-cabling (if necessary with fillers)<br />

dry filled cable core<br />

strength members (glass-rovings)<br />

ripcord<br />

PE-sheath, UV-resistant, black with two orange longitudinal stripes<br />

Fiber colours<br />

1-12: red, green, yellow, blue, white, violet, orange, black, grey, brown, pink, turquoise<br />

13-24: red, green, yellow, blue, white, violet, orange, transparent, grey, brown, pink, turquoise -each with black rings every 50 mm (max.)<br />

Tube colours<br />

1: red<br />

2: green<br />

o<strong>the</strong>rs: nature or white<br />

Filler colours<br />

black<br />

Laying<br />

usable for fixed laying in ducts or conduits and outdoors<br />

Marking<br />

double-sinus, phone-sign, meter marking, PENGG KABEL, year of manufacturing<br />

Technical Data<br />

tensile strength:<br />

compressive strength:<br />

impact strength:<br />

<strong>to</strong>rsion:<br />

kink, cable:<br />

kink, loose tube:<br />

min. bending radius:<br />

temperature range:<br />

water penetration:<br />

according <strong>to</strong> IEC 60794-1-E1<br />

according <strong>to</strong> IEC 60794-1-E3 | value: 3000 N/10 cm<br />

according <strong>to</strong> IEC 60794-1-E4 | value: 10 Nm<br />

according <strong>to</strong> IEC 60794-1-E7 | value: 5 cycles ±1 turn<br />

according <strong>to</strong> IEC 60794-1-E10 | value: The cables do not form a kink when a loop is drawn <strong>to</strong>ge<strong>the</strong>r <strong>to</strong> a<br />

diameter 12 times <strong>the</strong> cable nominal diameter.<br />

according <strong>to</strong> IEC 60794-1-E16 | value: The loose tubes do not kink.<br />

according <strong>to</strong> IEC 60794-1-E11 | value: R = 20 x D (cable outer diameter)<br />

according <strong>to</strong> IEC 60794-1-F1<br />

s<strong>to</strong>rage and transport: -40°C up <strong>to</strong> +70°C<br />

laying:<br />

-5°C up <strong>to</strong> +60°C<br />

operation:<br />

-30°C up <strong>to</strong> +70°C<br />

according <strong>to</strong> IEC 60794-1-F5 | value: No water on free end.

A-DQ(ZN)2Y Mini T - Mini cable, loose tube construction, D15-S05<br />

outdoor cable<br />

metal-free<br />

longitudinally<br />

water-tight<br />

A-DQ(ZN)2Y Mini T 2x12E9/125 blue Art. No. 2035144<br />

A-DQ(ZN)2Y Mini T 4x12E9/125 red Art. No. 2035145<br />

A-DQ(ZN)2Y Mini T 6x12E9/125 violet Art. No. 2035146<br />

A-DQ(ZN)2Y Mini T 8x12E9/125 pink Art. No. 2035147<br />

A-DQ(ZN)2Y Mini T 12x12E9/125 grey Art. No. 2035148<br />

Type number of number of tubes tube-Ø tensile strength outer-Ø weight<br />

<strong>fiber</strong>s + fillers approx. mm max. N approx. mm approx. kg/km<br />

A-DQ(ZN)2Y Mini T 2x12E9/125 blue 24 2 + 4 1,5 700 5,6 29,1<br />

A-DQ(ZN)2Y Mini T 4x12E9/125 red 48 4 + 2 1,5 700 5,6 30,0<br />

A-DQ(ZN)2Y Mini T 6x12E9/125 violet 72 6 + 0 1,5 700 5,6 30,8<br />

A-DQ(ZN)2Y Mini T 8x12E9/125 pink 96 8 + 0 1,5 700 6,5 44,5<br />

A-DQ(ZN)2Y Mini T 12x12E9/125 grey 144 12 + 0 1,5 700 8,5 64,1<br />

Stranded mini tube cable for laying in<strong>to</strong> micro ducts.<br />

This cable is used in access networks as both connection between <strong>fiber</strong> distributers and house connection for multi dwelling units. Fibers<br />

according ITU-T G.657.A1.<br />

Due <strong>to</strong> both <strong>the</strong> deployed <strong>fiber</strong>s and its light construction it is suitable for small bending radii.<br />

Construction<br />

central member, metal free<br />

loose buffer tube filled with a thixotropic gel, swellable aramid yarns<br />

dry filled cable core<br />

rip cord<br />

PE-sheath<br />

Fiber colours<br />

1-12: red, green, yellow, blue, white, violet, orange, black, grey, brown, pink, turquoise<br />

Tube colours<br />

1: red<br />

2: green<br />

o<strong>the</strong>rs: nature or white<br />

Filler colours<br />

black<br />

Marking<br />

double-sinus, phone-sign, meter marking, PENGG KABEL, year of manufacturing<br />

Technical Data<br />

tensile strength: according <strong>to</strong> IEC 60794-1-E1<br />

compressive strength: according <strong>to</strong> IEC 60794-1-E3 | value: 1000 N/10 cm<br />

impact strength: according <strong>to</strong> IEC 60794-1-E4 | value: 5 Nm (3 impacts, 300 mm hammer radius)<br />

min. bending radius: according <strong>to</strong> IEC 60794-1-E11 | values: static R = 10 x D, dynamic R = 20 x D (cable outer diameter)<br />

temperature range: according <strong>to</strong> IEC 60794-1-F1<br />

s<strong>to</strong>rage and transport -30°C up <strong>to</strong> +60°C<br />

laying<br />

-5°C up <strong>to</strong> +50°C<br />

operation<br />

-30°C up <strong>to</strong> +60°C<br />

water penetration: according <strong>to</strong> IEC 60794-1-F5 | value: ≤1 m (0,1 bar, 24 h)<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

9

A-DQ(ZN)2Y Mini CT - Mini cable, central unitube, D30-S04<br />

outdoor cable<br />

metal-free<br />

longitudinally<br />

water-tight<br />

A-DQ(ZN)2Y Mini CT 12E9/125 yellow Art. No. 2035142<br />

A-DQ(ZN)2Y Mini CT 24E9/125 blue Art. No. 2035143<br />

Type number of number of tube-Ø Zugfestigkeit outer-Ø weight<br />

<strong>fiber</strong>s/tube <strong>fiber</strong>s approx. mm max. N approx. mm approx. kg/km<br />

A-DQ(ZN)2Y Mini CT 12E9/125 yellow 12 12 3,0 400 3,9 12,9<br />

A-DQ(ZN)2Y Mini CT 24E9/125 blue 24 24 3,0 400 3,9 13,8<br />

Central mini tube cable for laying in<strong>to</strong> micro ducts.<br />

This cable is used in access networks as drop cable <strong>to</strong> house connections. Fibers according ITU-T G.657.A1. Due <strong>to</strong> both <strong>the</strong> deployed<br />

<strong>fiber</strong>s and its light construction it is suitable for small bending radii.<br />

Construction<br />

center unitube<br />

strength members (aramide yarns)<br />

PE-sheath<br />

Fiber colours<br />

1-12: red, green, yellow, blue, white, violet, orange, black, grey, brown, pink, turquoise<br />

13-24: red, green, yellow, blue, white, violet, orange, transparent, grey, brown, pink, turquoise -each with black rings every 50 mm (max.)<br />

Tube colour<br />

red<br />

Marking<br />

double-sinus, phone-sign, meter marking, PENGG KABEL, year of manufacturing<br />

Technical Data<br />

tensile strength:<br />

compressive strength:<br />

impact strength:<br />

min. bending radius:<br />

temperature range:<br />

according <strong>to</strong> IEC 60794-1-E1<br />

according <strong>to</strong> IEC 60794-1-E3 | value: 1000 N/10 cm<br />

according <strong>to</strong> IEC 60794-1-E4 | value: 1 Nm (3 impacts, 300 mm Hammer radius)<br />

according <strong>to</strong> IEC 60794-1-E11 | value: static R = 20 x D (cable outer diameter)<br />

according <strong>to</strong> IEC 60794-1-F1<br />

s<strong>to</strong>rage and transport -30°C up <strong>to</strong> +70°C<br />

laying<br />

-5°C up <strong>to</strong> +50°C<br />

operation<br />

-20°C up <strong>to</strong> +70°C

I-VQ(ZN)H 4E9/125 FTTH-Inhouse cable - Inhouse cable, V06<br />

inhouse cable<br />

metal-free<br />

halogenfree,<br />

flame retardant<br />

I-VQ(ZN)H 4E9/125 FTTH-Inhouse cable Art. No. 2035149<br />

Type number of tube-Ø number of tubes tensile strength *) outer-Ø weight<br />

<strong>fiber</strong>s approx. µm + fillers max. N approx. mm approx. kg/km<br />

I-VQ(ZN)H 4E9/125 FTTH-Inhouse cable 4 600 4 + 0 400 2.8 7,5<br />

*) with reversible attenuation increase<br />

FTTH in-house cable, suitable for laying within buildings in both horizontal and vertical ways.<br />

This cable is suitable for direct assembling with connec<strong>to</strong>rs. Fibers according ITU-T G.657.A1.<br />

Construction<br />

4 buffered <strong>fiber</strong>s (silikon-coated, 600 microns)<br />

strength members (aramide yarns)<br />

FRNC-sheath according <strong>to</strong> IEC 60332-3, UV-resistant<br />

Fiber colours<br />

red, green, yellow, blue<br />

Mantelfarbe<br />

grey<br />

Marking<br />

letter symbol of <strong>fiber</strong> type, meter marking, PENGG KABEL, year of manufacturing<br />

Technical Data<br />

standard: IEC 60794<br />

tensile strength: according <strong>to</strong> IEC 60794-1-E1<br />

compressive strength: according <strong>to</strong> IEC 60794-1-E3 | value: 500 N/10 cm<br />

bending radius: static 15 x cable outer diameter<br />

dynamic 20 x cable outer diameter<br />

temperature range: s<strong>to</strong>rage and transport -25°C up <strong>to</strong> +70 °C<br />

laying -5°C up <strong>to</strong> +50 °C<br />

operation -5°C up <strong>to</strong> +50 °C<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

11

Fiber optic enclosure<br />

SEC15 for max. 128 splices<br />

Description<br />

• The SEC15 dome enclosure is particularly suitable for connecting fibre optic cables featuring a small number of fibres<br />

• Enclosure for in-line connections and branch-offs<br />

• Suitable for underground, duct, wall and pole/<strong>to</strong>wer mounting<br />

• Suitable for uncut cables<br />

• Assembly/disassembly of <strong>the</strong> dome without any <strong>to</strong>ols<br />

• Sealings can be used again<br />

• Separate strain relief points for central strength member and Kevlar reinforcement<br />

• S<strong>to</strong>rage of cut/uncut multi-fibre loose tubes<br />

• Cable entries for max.<br />

1 oval entry for 2x10-25 mm cables<br />

3 entries for 10-20 mm cables<br />

• Splice cassettes (order separate) 8 x SK120S<br />

• Degree of protection<br />

>IP68<br />

• Max. splice capacity<br />

Splice protection tube 128<br />

• Tests according <strong>to</strong> DIN 47624 Draft 4/97<br />

Mechanical strength<br />

Load (15 min)<br />

1000 N at <strong>the</strong> centre of <strong>the</strong> enclosure,<br />

contact area 5 cm 2<br />

Impact (once)<br />

1 kg Steel ball, 2 m fall,<br />

at <strong>the</strong> centre of <strong>the</strong> enclosure<br />

Pressure resistance<br />

Permanent pressure<br />

0.4 bar above atmospheric<br />

Tight from<br />

-40°C <strong>to</strong> +70C°<br />

Tightness with cable<br />

Strain (15 min)<br />

1000 N<br />

Shearing/bending (twice)<br />

Deflection 45° or a max. of 500 N bending force,<br />

Point of application 250 mm from cable entry<br />

Torsion (twice)<br />

±90° rotation angle or a max. <strong>to</strong>rque of 50 Nm,<br />

Point of application 500 mm from cable entry<br />

Vibration<br />

168 hours; both cable ends fastened,<br />

Amplitude ±3 mm, frequency 10 Hz<br />

Temperature changes<br />

-40°C <strong>to</strong> +70°C, 10 times<br />

Immersion in wetting agent<br />

168 hours<br />

External pressure resistance<br />

4 m water column<br />

Water vapour permeation

SEC23 Tubeless short for max. 288 / 432 splices<br />

Description<br />

• Tubeless version suitable especially for Single Circuit (SC) and Single Element (SE).<br />

Single Circuit: Distribution of <strong>the</strong> fibres from one multi-fibre loose tube <strong>to</strong> several splice cassettes through fibre guiding channels<br />

• Tubeless laying of <strong>the</strong> fibres from entry <strong>to</strong> splice cassette<br />

• In-line connection and branch-off enclosure<br />

• Suitable for ground, duct, wall, pole and <strong>to</strong>wer mounting<br />

• “Short” version especially for manholes or cable ducts<br />

• Suitable for uncut cables<br />

• Assembly/disassembly of <strong>the</strong> dome without any <strong>to</strong>ols<br />

• Sealings can be used again<br />

• Separate strain relief points for central strength member and Kevlar reinforcement<br />

• An entry module permits fibre guidance <strong>to</strong> any desired cassette entry<br />

• Cable entries for max.<br />

1 oval entry for 2x10-25 mm cables<br />

4 entries for 10-20 mm cables<br />

2 entries for 10-25 mm cables<br />

• Splice cassettes (order separate) 36 x SK123 (SE) or SK223 (SC)<br />

Available in cassette sets of 6 splice cassettes each ⇒ max. 6 sets (3 units on ei<strong>the</strong>r side).<br />

Splice cassettes engaged in a slanted position<br />

Pivoting splice cassettes (90°) <strong>to</strong> provide easy access <strong>to</strong> each splice<br />

• Degree of protection<br />

>IP68<br />

• Max. splice capacity<br />

2x4 splices at each SK223 (SC) 288<br />

12 splices at each SK123 (SE) 432<br />

• Tests according <strong>to</strong> DIN 47624 Draft 4/97<br />

Mechanical strength<br />

Load (15 min) 1000 N at centre of <strong>the</strong> enclosure, contact area 5 cm 2<br />

Impact (once)<br />

1 kg steel ball, 2 m fall, centre of <strong>the</strong> enclosure<br />

Pressure resistance<br />

Permanent pressure<br />

0.4 bar above atmospheric<br />

Tight from<br />

-40°C <strong>to</strong> +70C°<br />

Tightness with cable<br />

Strain (15 min)<br />

1000 N<br />

Shearing/bending (twice)<br />

Deflection 45° or a max. of 500 N bending force,<br />

Point of application 250 mm from cable entry<br />

Torsion (twice)<br />

±90° rotation angle or a max. <strong>to</strong>rque of 50 Nm,<br />

Point of application 500 mm from cable entry<br />

Vibration<br />

168 hours; both cable ends fastened,<br />

Amplitude ±3 mm, frequency 10 Hz<br />

Temperature changes<br />

-40°C <strong>to</strong> +70°C, 10 times<br />

Immersion in wetting agent<br />

168 hours<br />

External pressure resistance<br />

4 m water column<br />

Water vapour permeation

SEC23 Tubeless classic for max. 576 / 864 splices<br />

Description<br />

• Tubeless version suitable especially for Single Circuit (SC) and Single Element (SE).<br />

Single Circuit: Distribution of <strong>the</strong> fibres from one multi-fibre loose tube <strong>to</strong> several splice cassettes through fibre guiding channels<br />

• Tubeless laying of <strong>the</strong> fibres from entry <strong>to</strong> splice cassette<br />

• In-line connection and branch-off enclosure<br />

• Suitable for ground, duct, wall, pole and <strong>to</strong>wer mounting<br />

• Suitable for uncut cables<br />

• Assembly/disassembly of <strong>the</strong> dome without any <strong>to</strong>ols<br />

• Sealings can be used again<br />

• Separate strain relief points for central strength member and Kevlar reinforcement<br />

• An entry module permits fibre guidance <strong>to</strong> any desired cassette entry<br />

• Cable entries for max.<br />

1 oval entry for 2x10-25 mm cables<br />

4 entries for 10-20 mm cables<br />

2 entries for 10-25 mm cables<br />

• Splice cassettes (order separate) 72 x SK123 (SE) or SK223 (SC)<br />

Available in cassette sets of 6 splice cassettes each ½ max. 12 sets (6 units on ei<strong>the</strong>r side).<br />

Splice cassettes engaged in a slanted position<br />

Pivoting splice cassettes (90°) <strong>to</strong> provide easy access <strong>to</strong> each splice<br />

• Degree of protection<br />

>IP68<br />

• Max. splice capacity<br />

2x4 splices at each SK223 (SC) 576<br />

12 splices at each SK123 (SE) 864<br />

• Tests according <strong>to</strong> DIN 47624 Draft 4/97<br />

Mechanical strength<br />

Load (15 min) 1000 N at centre of <strong>the</strong> enclosure, contact area 5 cm 2<br />

Impact (once)<br />

1 kg steel ball, 2 m fall, centre of <strong>the</strong> enclosure<br />

Pressure resistance<br />

Permanent pressure<br />

0.4 bar above atmospheric<br />

Tight from<br />

-40°C <strong>to</strong> +70C°<br />

Tightness with cable<br />

Strain (15 min)<br />

1000 N<br />

Shearing/bending (twice)<br />

Deflection 45° or a max. of 500 N bending force,<br />

Point of application 250 mm from cable entry<br />

Torsion (twice)<br />

±90° rotation angle or a max. <strong>to</strong>rque of 50 Nm,<br />

Point of application 500 mm from cable entry<br />

Vibration<br />

168 hours; both cable ends fastened,<br />

Amplitude ±3 mm, frequency 10 Hz<br />

Temperature changes<br />

-40°C <strong>to</strong> +70°C, 10 times<br />

Immersion in wetting agent<br />

168 hours<br />

External pressure resistance<br />

4 m water column<br />

Water vapour permeation

Fiber optic enclosures - accessories<br />

Cable entry sets (shrinking)<br />

• Sealing set for standard connection bushes of <strong>the</strong> SEC 15 and SEC 23 versions<br />

• For sealing cables with a PE-jacket<br />

• Excellent tightness and mechanical strength<br />

• Material: Cross-linked polyolefine, inside coated with <strong>the</strong>rmoplastic adhesive<br />

• Scope of delivery: Heat-shrinkable sleeve, emery cloth, cable cleaning cloth, cable tie wraps,<br />

installation material; 1 additional branch-off clamp coming with <strong>the</strong> oval cable entry set<br />

Oval cable entry set 2x10-20 mm Art. No. 2735176<br />

Round cable entry set 10-20 mm Art. No. 2735177<br />

Round cable entry set 10-25 mm Art. No. 2735178<br />

Microtube entries<br />

As an alternative <strong>to</strong> <strong>the</strong> shrinking entries <strong>the</strong>re are microduct launches 16/12 mm 14/10 mm, 12/8 mm available on request.<br />

Microtube entries<br />

on request<br />

Splice cassette SK120 á 16 splices<br />

Stripping dimensions<br />

(cm):<br />

Windings Min. Max.<br />

1.5 59 68<br />

2 76 86<br />

2.5 89 105<br />

3 108 125<br />

3.5 124 144<br />

With <strong>the</strong> possibility for mounting <strong>the</strong> hinge:<br />

• Splice s<strong>to</strong>rage for all kinds of optical fibres<br />

• Splice cassettes can be piled one on <strong>to</strong>p of <strong>the</strong> o<strong>the</strong>r<br />

• With or without <strong>the</strong> possibility for mounting <strong>the</strong> hinge<br />

• Installation of different splice protection holders is possible through <strong>the</strong> snap-on system<br />

• Laying in an 8-shaped loop is possible<br />

• Bending radius: >30 mm<br />

• Capacity<br />

Splices<br />

16 splice protection tubes Ø 2.5 mm (heat-shrinkable)<br />

Splice protection holders 2x ...-SRH8<br />

• Reserve fibre length approx. 40 m<br />

• Material: Polystyrene<br />

• Weight: 36 g<br />

• Scope of delivery: 1 Splice cassette (excl. splice protection holder, excl. hinge)<br />

Without <strong>the</strong> possibility for mounting <strong>the</strong> hinge:<br />

Splice cassette SK120 á 16 splices Art. No. 2735179<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

15

Splice cassette set SK123 6xSE á 12 splices<br />

• The splice cassette set serves for guiding fibres from <strong>the</strong> entry module <strong>to</strong> <strong>the</strong> splice cassette and for<br />

splice s<strong>to</strong>rage of all kinds of optical fibres<br />

• Installation of max. 6 splice cassette sets in <strong>the</strong> SEC23 Tubeless short enclosure and max. 12 splice<br />

cassette sets in <strong>the</strong> SEC23 Tubeless classic enclosure<br />

• Cassette base plate with guiding channels for fibres and fastening options for a max. of 6 splice<br />

cassettes LWL-SK123 (SE)<br />

• Versions for heat-shrinkable (splice protection tubes)<br />

• Material: Polycarbonate VL94HB, colour RAL 9001<br />

• Weight: 0,3 kg<br />

• Scope of delivery: 1 cassette base plate, 6 LWL-SK123 splice cassettes<br />

Splice cassette set SK123 6xSE á 12 splices Art. No. 2735180<br />

Splice cassette set SK223 6xSC á 2x4 splices<br />

• The splice cassette set serves for guiding fibres from <strong>the</strong> entry module <strong>to</strong> <strong>the</strong> splice cassette and for<br />

splice s<strong>to</strong>rage of all kinds of optical fibres<br />

• Installation of max. 6 splice cassette sets in <strong>the</strong> SEC23 Tubeless short enclosure and max. 12 splice<br />

cassette sets in <strong>the</strong> SEC23 Tubeless classic enclosure<br />

• Cassette base plate with guiding channels for fibres and fastening options for a max. of 6 splice<br />

cassettes LWL-SK223 (SC)<br />

• Versions for heat-shrinkable (splice protection tubes)<br />

• Material: Polycarbonate VL94HB, colour RAL 9001<br />

• Weight: 0,47 kg<br />

• Scope of delivery: 1 cassette base plate, 6 LWL-SK223 splice cassettes<br />

Splice cassette set SK223 6xSC á 2x4 splices Art. No. 2735181<br />

Wall-mounting set for SEC15, SEC23<br />

• Fastening angle for convenient wall-mounting<br />

• Material: Powder-coated 3-mm aluminium sheet, RAL 7035<br />

• Scope of delivery: Wall-mounting set<br />

SEC23<br />

SEC15<br />

SEC23 Short<br />

Wall-mounting set for SEC 15 Art. No. 2735182<br />

Wall-mounting set for SEC 23 Art. No. 2735183

Outdoor cabinet<br />

KVZ F5 1080/320 OPDISYS ®<br />

Technical characteristics:<br />

• Material housing and base<br />

polycarbonate<br />

• Color housing and base RAL 7038<br />

• Protection class<br />

IP54<br />

• Capacity of <strong>fiber</strong> modules 16 OPDISYS ® Modules (16HU) at a housing size (WxHxD) 998 x 754 x 310<br />

• Gas blocker permanently integrated<br />

• Door with swivel handle, prepared for two half profile cylinder<br />

• Fiber optic fixing kit made of stainless steel<br />

KVZ F5 1080/320 OPDISYS ® Art. No. 2735184<br />

Fiber module 24 LC/APC, 1HU Art. No. 2535159<br />

Fiber module 24 E2000/APC, 1HU Art. No. 2535160<br />

Fiber module 12 SC/APC, 1HU Art. No. 2535161<br />

Fiber module for up <strong>to</strong> 48 splices, 1HU Art. No. 2535162<br />

KVZ small as splicing version - equipped with 2x6 splice cassettes sets of SEC23 on request<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

17

Cable manhole<br />

EK 428 LW 800x1400<br />

Low weight<br />

• An advantage when transporting and handling. Easy<br />

delivery <strong>to</strong> inaccessible sites, such as along railway lines<br />

or inner-city areas<br />

• Minimal installation effort<br />

• No heavy transporters or cranes required<br />

Modular construction<br />

• Manhole depths and connection positions are variable by<br />

means of <strong>the</strong> combination of framework modules<br />

Superstructure about existing pipe extrusion lines<br />

• Without any difficulty bonding of existing pipeline<br />

alignment through open side parts in connection with<br />

<strong>the</strong> accessory<br />

• Through <strong>the</strong> low weight <strong>the</strong> bonding is acutely easy<br />

Practical product<br />

• Infinitely variable height and angle compensation<br />

• Exact-fit pipe connections by means of set break points<br />

• Sealing elements for cables without tubing<br />

Stability<br />

• High degree of stability with low inherent weight, resulting<br />

from <strong>the</strong> use of high-quality plastic<br />

• Optimum embedding in <strong>the</strong> surrounding soil<br />

• Mechanical protection of <strong>the</strong> <strong>to</strong>p edge provided by hot-dip<br />

galvanised steel frame<br />

Material<br />

• For all load-bearing elements made of plastic: Modified polycarbonate (PC)<br />

• High temperature resistance<br />

• Surface finish not critical affected by hot or melted asphalt<br />

• High degree of stability<br />

• Fireproof<br />

• Corrosion-proof<br />

• Highly resistant <strong>to</strong> chemicals<br />

• Highly resistant <strong>to</strong> UV light and wea<strong>the</strong>ring<br />

• Recyclable several times over

Fittings<br />

• Up <strong>to</strong> 2 sleeves (SEC15 or SEC23) for direct buried <strong>fiber</strong> optic cables<br />

or micro tubes with swiveling telescopic sleeve holder for a optimum<br />

working position<br />

Manhole cover<br />

Manhole cover in various versions:<br />

• Cast iron (with lock) - D400 (400 kN testing force)<br />

• Steel filled with concrete (with lock) - D400 (400 kN testing force)<br />

• Bulb plate (with screwed) - A15 (15 kN testing force)<br />

Accessories<br />

• Under cover fuse for protection against damage <strong>to</strong> <strong>the</strong> fittings<br />

• Moni<strong>to</strong>ring system for central moni<strong>to</strong>ring of access<br />

Dimensions and test classes<br />

• clear dimension: 800 x 1400 mm<br />

• External height: 935 mm<br />

• Test class: D400 and A15<br />

EK 428 LW 800x1400 with cast iron cover (consisting of 4 parts) Art. No. 2735185<br />

EK 428 LW 800x1400 with bulb plate cover (consisting of 3 parts) Art. No. 2735186<br />

EK 428 LW 800x1400 with steel cover<br />

on request<br />

Telescopic sleeve holder Art. No. 2735187<br />

O<strong>the</strong>r manhole types<br />

on request<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

19

House lead-in<br />

EK 459 for micro-tubes, gas-tight<br />

This house lead is specially designed for <strong>the</strong> sealing of <strong>fiber</strong> optic cable in<br />

<strong>the</strong> introduction in building walls. It is suitable for all wall types (DIN<br />

1819T.4) as suitable for foundations made of waterproof concrete.<br />

The foaming principle guarantees a perfect seal.<br />

Technical characteristics:<br />

• Required bore diameter of only 40 mm<br />

• Cover a large range of diameters of m micro-tubes: 7-14 mm single<br />

introduction and 7 mm double insertion<br />

• Wall thickness: 400 mm standard, o<strong>the</strong>rs upon request<br />

• Delivery option for micro-tube diameters from 2 <strong>to</strong> 8 mm<br />

• Gas-tight and waterproof up <strong>to</strong> 4 m water column<br />

• Due <strong>to</strong> funnel-shaped silicone sealing discs technology only minimum<br />

effort pushing in <strong>the</strong> micro-tube / <strong>fiber</strong> optic cable, <strong>the</strong>refore no risk of<br />

kinking <strong>the</strong> line<br />

• About quick-grid-screw flange permanent pressing of <strong>the</strong> plastic sealing<br />

bead (outside of building)<br />

• Fast and gentle on <strong>the</strong> material sealing <strong>the</strong> micro-tubes / <strong>fiber</strong> optic cables<br />

EK 459 for micro-tubes, gas-tight, for wall thicknesses up <strong>to</strong> 400 mm Art. No. 2735214<br />

O<strong>the</strong>r house lead-in<br />

on request

Microtube<br />

Micro tubes are made of high density polyethylene (HDPE) and Silicore (super smooth inner surface,<br />

co-extruded with HDPE, allows higher injection and retraction speeds and lengths) were prepared<br />

and used <strong>to</strong> protect optical <strong>fiber</strong> cable.<br />

Inner surface is made from permanent sliding material Silicore with a very low coefficient of friction<br />

and standardly with fine ribs. Outer microduct’s surface is smooth. Microduct is not designed for<br />

permanent inner pressure.<br />

Microduct does not contain dangerous chemicals in accordance <strong>to</strong> <strong>the</strong> Directive 2006/1907/EC<br />

(REACH). Microduct meets requirements of <strong>the</strong> Directive 2002/95/EC (RoHS) - content of lead, cadmium,<br />

mercury, Cr VI , PBB und PBDE.<br />

General specification<br />

Parameter Value Standard, conditions<br />

Ovality max. 5% Internal standard, before coiling<br />

Inner coefficient of friction max. 0,1 Internal standard<br />

Visual examination free from defects Internal standard<br />

Crush - pressure force min. 1000 N EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

ID deformation by 15%, speed 3 mm/min.<br />

Impact<br />

no damage after <strong>the</strong> test,<br />

dimens. in <strong>to</strong>lerances after recovery<br />

EN 60794-1-2, method E4, striking surface<br />

radius 10 mm, impact energy 15 J, recovery time 1 h<br />

Thermal expansion 1,6.10 -4 K 1 ISO 11359-2, temperature range from -20°C <strong>to</strong> +70°C<br />

Longitudinal reversion max. 3% EN ISO 2505, oven, 110°C, 60 min.<br />

Transport and s<strong>to</strong>rage temperatures from -40°C <strong>to</strong> +70°C -<br />

Installation temperatures from -10°C <strong>to</strong> +50°C -<br />

Operating temperatures from -40°C <strong>to</strong> +70°C -<br />

Blowing pressure max. 20 bar max. 2 hours at max. +50°C<br />

Outdoor exposure (central eurpope conditions) max. 12 months -<br />

Microduct DB 7/4 - recommended cable outer diameter from 1,0 <strong>to</strong> 2,5 mm<br />

Parameter Value Standard, conditions<br />

Outer diameter (OD) 7±0,1 mm Internal standard<br />

Inner diameter (ID) min. 3,9 mm Internal standard<br />

Wall thickness (WT) min. 1,4 mm Internal standard<br />

Blown ball test (BB-test) pass Internal standard, ball diameter 3,5 mm<br />

Burst pressure min. 70 bar EN ISO 1167-1, 2<br />

Crush - residual deformation max. 15% OD = max. 1,1 mm EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

force 1718 N, 3 mm/min., aktion 60 s, recovery 20 s<br />

Bending stiffness min. 0,04 N.m 2 Internal standard<br />

Standard Dimension Ratio (SDR = OD/WT) 4,7 -<br />

Weight 25 kg/km -<br />

Installation tensile force max. 350 N -<br />

Minimum bending 70 mm -<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

21

Microduct DB 10/6 - recommended cable outer diameter from 2,0 <strong>to</strong> 4,5 mm<br />

Parameter Value Standard, conditions<br />

Outer diameter (OD) 10±0,1 mm Internal standard<br />

Inner diameter (ID) min. 5,9 mm Internal standard<br />

Wall thickness (WT) min. 1,9 mm Internal standard<br />

Blown ball test (BB-test) pass Internal standard, ball diameter 5,0 mm<br />

Burst pressure min. 70 bar EN ISO 1167-1, 2<br />

Crush - residual deformation max. 15% OD = max. 1,5 mm EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

force 2100 N, 3 mm/min., aktion 60 s, recovery 20 s<br />

Bending stiffness min. 0,19 N.m 2 Internal standard<br />

Standard Dimension Ratio (SDR = OD/WT) 5 -<br />

Weight 47,5 kg/km -<br />

Installation tensile force max. 680 N -<br />

Minimum bending 100 mm -<br />

Microduct DB 12/8 - recommended cable outer diameter from 4,0 <strong>to</strong> 6,5 mm<br />

Parameter Value Standard, conditions<br />

Outer diameter (OD) 12±0,1 mm Internal standard<br />

Inner diameter (ID) min. 7,9 mm Internal standard<br />

Wall thickness (WT) min. 1,9 mm Internal standard<br />

Blown ball test (BB-test) pass Internal standard, ball diameter 6,5 mm<br />

Burst pressure min. 60 bar EN ISO 1167-1, 2<br />

Crush - residual deformation max. 15% OD = max. 1,8 mm EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

force 1680 N, 3 mm/min., aktion 60 s, recovery 20 s<br />

Bending stiffness min. 0,36 N.m 2 Internal standard<br />

Standard Dimension Ratio (SDR = OD/WT) 6 -<br />

Weight 59 kg/km -<br />

Installation tensile force max. 840 N -<br />

Minimum bending 120 mm -<br />

Microduct DB 14/10 - recommended cable outer diameter from 5,0 <strong>to</strong> 8,5 mm<br />

Parameter Value Standard, conditions<br />

Outer diameter (OD) 14±0,1 mm Internal standard<br />

Inner diameter (ID) min. 9,9 mm Internal standard<br />

Wall thickness (WT) min. 1,9 mm Internal standard<br />

Blown ball test (BB-test) pass Internal standard, ball diameter 8,0 mm<br />

Burst pressure min. 50 bar EN ISO 1167-1, 2<br />

Crush - residual deformation max. 15% OD = max. 2,1 mm EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

force 1400 N, 3 mm/min., aktion 60 s, recovery 20 s<br />

Bending stiffness min. 0,61 N.m 2 Internal standard<br />

Standard Dimension Ratio (SDR = OD/WT) 7 -<br />

Weight 72 kg/km -<br />

Installation tensile force max. 1010 N -<br />

Minimum bending 140 mm -<br />

Microduct DB 16/12 - recommended cable outer diameter from 7,0 <strong>to</strong> 10,0 mm<br />

Parameter Value Standard, conditions<br />

Outer diameter (OD) 16±0,1 mm Internal standard<br />

Inner diameter (ID) min. 11,9 mm Internal standard<br />

Wall thickness (WT) min. 1,9 mm Internal standard<br />

Blown ball test (BB-test) pass Internal standard, ball diameter 10,0 mm<br />

Burst pressure min. 40 bar EN ISO 1167-1, 2<br />

Crush - residual deformation max. 15% OD = max. 2,4 mm EN 60794-1-2, E3, sample 200 mm, aktive 100 mm,<br />

force 1200 N, 3 mm/min., aktion 60 s, recovery 20 s<br />

Bending stiffness min. 0,94 N.m 2 Internal standard<br />

Standard Dimension Ratio (SDR = OD/WT) 8 -<br />

Weight 84 kg/km -<br />

Installation tensile force max. 1150 N -<br />

Minimum bending 160 mm -<br />

Microduct 7/4 (for cables from 1,0 - 2,5 mm) Art. No. 2735188<br />

Microduct 10/6 (for cables from 2,0 - 4,5 mm) Art. No. 2735189<br />

Microduct 12/8 (for cables from 4,0 - 6,5 mm) Art. No. 2735190<br />

Microduct 14/10 (for cables from 5,0 - 8,5 mm) Art. No. 2735191<br />

Microduct 16/12 (for cables from 7,0 - 10,0 mm) Art. No. 2735192

Metal free micro duct connec<strong>to</strong>r<br />

• Body material:<br />

Polyamide<br />

• Spring material: Polyacetal<br />

• Seal material:<br />

NBR<br />

• Temperature range: -20°C <strong>to</strong> +50°C<br />

• Working pressure: max. 20 bar<br />

• Lifespan:<br />

25 years<br />

• Standards: EN 50441-2-8<br />

Available sizes<br />

(Dimension length / width / through bore / tensile force [N])<br />

Connec<strong>to</strong>r for microducts 7/3.5 mm 42 / 17 / 3.5 / 150 N<br />

Connec<strong>to</strong>r for microducts 10/5.5 mm 48 / 20.5 / 5.5 / 250 N<br />

Connec<strong>to</strong>r for microducts 12/8 mm 52 / 23 / 8.0 / 530 N<br />

Connec<strong>to</strong>r for microducts 14/10 mm 60 / 25.5 / 10.0 / 1000 N<br />

Connec<strong>to</strong>r for microducts 16/12 mm 67 / 30 /12.0 / 1500 N<br />

Metal free micro duct connec<strong>to</strong>r 7 mm Art. No. 2735193<br />

Metal free micro duct connec<strong>to</strong>r 10 mm Art. No. 2735194<br />

Metal free micro duct connec<strong>to</strong>r 12 mm Art. No. 2735195<br />

Metal free micro duct connec<strong>to</strong>r 14 mm Art. No. 2735196<br />

Metal free micro duct connec<strong>to</strong>r 16 mm Art. No. 2735197<br />

Metal free end s<strong>to</strong>p<br />

• Body material:<br />

Polyamide<br />

• Spring material: Polyacetal<br />

• Seal material:<br />

NBR<br />

• Temperature range: -20°C <strong>to</strong> +50°C<br />

• Impact resistance: 1000 - 4000 N<br />

• Working pressure: max. 20 bar<br />

• Lifespan:<br />

25 years<br />

• Standards: EN 50441-2-8<br />

Available sizes (Dimension length / width / tensile force [N])<br />

End s<strong>to</strong>p for 7 mm microducts 23 / 17.0 / 80 N<br />

End s<strong>to</strong>p for 10 mm microducts 26 / 20.5 / 150 N<br />

End s<strong>to</strong>p for 12 mm microducts 28 / 23.0 / 200 N<br />

End s<strong>to</strong>p for 14 mm microducts 33 / 25.5 / 300 N<br />

End s<strong>to</strong>p for 16 mm microducts 36.5 / 30.0 / 400N<br />

Metal free micro duct end s<strong>to</strong>p 7 mm Art. No. 2735198<br />

Metal free micro duct end s<strong>to</strong>p 10 mm Art. No. 2735199<br />

Metal free micro duct end s<strong>to</strong>p 12 mm Art. No. 2735200<br />

Metal free micro duct end s<strong>to</strong>p 14 mm Art. No. 2735201<br />

Metal free micro duct end s<strong>to</strong>p 16 mm Art. No. 2735202<br />

Divisible gasblock<br />

• Body material:<br />

• Seal material:<br />

• Gas seal pressure:<br />

reinforced glass<strong>fiber</strong> polyamid<br />

TPE<br />

0,5 bar<br />

Divisible gasblock 7<br />

(for 2,5 mm cables)<br />

Divisible gasblock 10<br />

(for cables from 2,5 - 3,9 mm)<br />

Divisible gasblock 12<br />

(for cables from 5,6 - 6,5 mm)<br />

Divisible gasblock 14<br />

(for 8,5 mm cable)<br />

Divisible gasblock 16<br />

(for 8,5 mm cable)<br />

Art. No. 2735203<br />

Art. No. 2735204<br />

Art. No. 2735205<br />

Art. No. 2735206<br />

Art. No. 2735207<br />

Microduct cutter and deburring <strong>to</strong>ol<br />

For clean and safe construction of <strong>the</strong><br />

microduct network, we recommend that you<br />

use <strong>the</strong> appropriate <strong>to</strong>ols:<br />

• Microduct cutter 4 - 12 mm<br />

• Microduct shear 4 - 28 mm<br />

• Deburring <strong>to</strong>ol<br />

Microduct shear 4 - 28 mm Art. No. 2735208<br />

Microduct cutter 4 - 12 mm Art. No. 2735209<br />

Deburring <strong>to</strong>ol Art. No. 2735210<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

23

Interconnect case<br />

OM10 BEP<br />

• The distribution enclosure serves as a termination for <strong>fiber</strong> optic cable <strong>to</strong> connec<strong>to</strong>r and for s<strong>to</strong>ring from splicing for max. 8 cus<strong>to</strong>mers <strong>fiber</strong>s<br />

(1 household)<br />

• Small termination box, especially suitable where space is limited<br />

• Suitable for indoor wall-mounting and installation in moist rooms<br />

• Pull-out splice s<strong>to</strong>rage frame with splice protection holders<br />

• Installation point for strain relief element (Kevlar)<br />

• Provides sufficient space for multi-fibre loose tube reserves under <strong>the</strong> splice s<strong>to</strong>rage frame<br />

• Entries<br />

Multi entry for 3 x I-VQ(ZN)H cable and PG9 cable gland<br />

• Splice protection holder<br />

1 SRH8 or 1 SWH12<br />

• Degree of protection of <strong>the</strong> empty enclosure<br />

IP54<br />

• Material<br />

Enclosure Polystyrene, similar <strong>to</strong> RAL 7035<br />

Splice s<strong>to</strong>rage frame Powder-coated aluminium, RAL 7035<br />

PG Cable entry gland<br />

Plastic<br />

• Weight<br />

Approx. 0.7 kg<br />

• Scope of delivery<br />

1 Enclosure, 1 splice s<strong>to</strong>rage frame, 1 copy of Instructions for Installation,<br />

1 PG9-cable gland, 2 cable tie wraps, 2 pigtail clips PC121, 1 SRH8/SWH12<br />

splice protection holder<br />

OM10 BEP for max. 8 cus<strong>to</strong>mer <strong>fiber</strong>s (1 household),<br />

incl. 1 Stk. splice s<strong>to</strong>rage frame<br />

Art. No. 2735211

RGV20 BEP<br />

• The interconnect case RGV 20 BEP is used for distribution of <strong>the</strong> <strong>fiber</strong>s in multiple dwellings <strong>to</strong> <strong>the</strong> specific house cabling for max. 96 cus<strong>to</strong>mer <strong>fiber</strong>s.<br />

• The tubeless version is particularly suitable for Single Circuit (SC) and Single Element (SE)<br />

Single Circuit: Distribution of <strong>the</strong> fibres from one multi-fibre loose tube <strong>to</strong> several splice cassettes through fibre guiding channels<br />

Single Element: For multi-fibre loose tube management (multi-fibre loose tube upon multi-fibre loose tube)<br />

• Tubeless laying of fibres from <strong>the</strong> entry <strong>to</strong> <strong>the</strong> splice cassette<br />

• Enclosure for in-line connections and branch-offs<br />

• Suitable for wall mounting<br />

• Door is right-hinged and easy <strong>to</strong> remove<br />

• Clip-down handle<br />

• Door sealing inside<br />

• Degree of protection IP 54 with PG cable entry<br />

• Strain relief points for central strength member and Kevlar reinforcement<br />

• S<strong>to</strong>rage area for cut/uncut multi-fibre loose tubes<br />

• The removable cassette-ground plate is used for fastening <strong>the</strong> multi-fibre loose tubes and also for<br />

assembling <strong>the</strong> splice cassette sets on<strong>to</strong> <strong>the</strong> mounting plate<br />

• The entry module permits fibre routing <strong>to</strong> any cassette entry<br />

• Cable entries<br />

PG cable entries<br />

Ø 8-10 mm (PG11)<br />

Ø 10-12 mm (PG13)<br />

Ø 12-14 mm (PG16)<br />

Ø 14-17 mm (PG21)<br />

24x Ø 3 mm (PG29) for I-VQ(ZN)H<br />

12 x SK123 (SE) or SK223 (SC)<br />

• Splice cassettes<br />

Available as sets of 6 splice cassettes each => max. 2 sets<br />

Splice cassettes are engaged in a slanted position<br />

Swing-type splice cassettes (90°) provide easy access <strong>to</strong> each splice<br />

• Permanent temperature Max. 150°C<br />

• Material<br />

Enclosure<br />

Thermoformed, self-extinguishing, halogen-free,<br />

glass-fibre reinforced polyester, colour RAL 7035<br />

Mounting-, Base plate Powder-coated sheet steel, RAL 7035<br />

Patch-, Fastening angle Powder-coated sheet steel, RAL 7011<br />

• Weight<br />

Approx. 5,1 kg<br />

• Scope of delivery<br />

1 Cabinet incl. door, clip-down handle and sealing,<br />

1 mounting plate, 1 base plate, 1 entry module with cover,<br />

1 fastening angle, 1 Angle with holes, fastening screws<br />

415 A<br />

315 B<br />

175 C<br />

RGV20 BEP basic casing empty Art. No. 2736264<br />

RGV20 BEP for max. 48 cus<strong>to</strong>mer <strong>fiber</strong>s<br />

(11 households), incl. 1 splice cassettes set (see page 16)<br />

RGV20 BEP for max. 96 cus<strong>to</strong>mer <strong>fiber</strong>s<br />

(23 households), incl. 2 splice cassettes sets (see page 16)<br />

Art. No. 2736265<br />

Art. No. 2735212<br />

OTO ZT 2xLC/APC<br />

• Fiber optic junction box for FTTH-inhouse cabling<br />

• For surface wall mounting<br />

• FTTH junction box for 1 <strong>to</strong> 4 <strong>fiber</strong>s<br />

• Consists of a metal mounting plate, a plastic housing with integrated <strong>fiber</strong> s<strong>to</strong>rage for cable and<br />

pigtail wires and integrated in <strong>the</strong> housing Shuttered<br />

• 2x LC / APC adapters including pigtails<br />

• Adapters with integrated laser protection<br />

• Labeling field with transparent cover<br />

• Color: white, similar <strong>to</strong> RAL 9010<br />

• Dimensions: 88x88x23 mm<br />

OTO ZT 2xLC/APC pigtails inserted - ready for splicing Art. No. 2535213<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

25

Heat shrinkable <strong>fiber</strong> optic splice protec<strong>to</strong>r<br />

Outer shrink tube: transparent, both ends preshrunk <strong>to</strong> closing <strong>the</strong> gap<br />

between <strong>the</strong> two tubes<br />

Inner shrink tube: transparent EVA hot melt adhesive (Ethylene vinyl<br />

acetate)<br />

Stainless steel with rounded ends <strong>to</strong> avoid <strong>fiber</strong> damage<br />

• Color<br />

transparent<br />

• Operating temperature -45 °C <strong>to</strong> +100 °C<br />

• Shrink temperature 110 °C<br />

• Tensile strength 18 MPa (acc. ASTM D2671)<br />

• Ultimate elongation 700 % (acc. ASTM D2671)<br />

• Density<br />

0,94 g/cm3 (acc. ISO R1183D)<br />

• Dielectric strength 25 kV/mm (acc. IEC 243)<br />

• Dielectric constant 2,5 (acc. IEC 243)<br />

• Longitudinal change ±5 % (acc. ASTM D2671)<br />

• Marking<br />

Pengg_MM.JJJJ<br />

Type<br />

Outer shrink tube<br />

(shrunk)<br />

outer-ø<br />

D1<br />

length<br />

L1<br />

Inner shrink tube<br />

(unshrunk)<br />

outer-ø<br />

D2<br />

length<br />

L2<br />

pin-ø<br />

D3<br />

Steel pin<br />

stainless<br />

length<br />

L3<br />

SP/F25/2,5A 2,45 ±0,1mm 25 ±0,5mm 1,3 ±0,3mm 25 ±0,5mm 1,0 ±0,05mm 21 ±0,1mm<br />

SP/F45/2,5A 2,45 ±0,1mm 45 ±0,5mm 1,3 ±0,3mm 45 ±0,5mm 1,0 ±0,05mm 41 ±0,1mm<br />

Heat shrinkable <strong>fiber</strong> optic splice<br />

protec<strong>to</strong>r SP/F25/2,5A<br />

Heat shrinkable <strong>fiber</strong> optic splice<br />

protec<strong>to</strong>r SP/F45/2,5A<br />

Art. No. 2735457<br />

Art. No. 2735456<br />

Adapter LC/APC 8 ° duplex flange with shutter<br />

• Adapter with flange or snap-on mounting with shutter<br />

Adapter LCdx/APC 8 ° duplex flange with shutter Art. No. 2736272<br />

19“ Fiber optic patch panel<br />

• Designed <strong>to</strong> s<strong>to</strong>rage <strong>fiber</strong> optic cables and splicing cassettes<br />

• Intended for installing in 19” rack system<br />

• Enable <strong>fiber</strong> optic termination and distribution<br />

• Model offered: Resetable and sliding<br />

• Installation depth: 250 mm<br />

• Material: steel<br />

• Powder coated<br />

• Colour: RAL 7035 (Light Grey) - o<strong>the</strong>r colours on request<br />

• Universal splice cassette holding system: fixed & booklet<br />

mounting option<br />

• Equipped with removable splice cassette holder and antitwist<br />

system<br />

• By default with 1 or 6 duplex adapters and pigtails<br />

19“ Fiber optic patch panel 24/1LCdx/APC 8° SM 1xPG16/1xAB RAL7035 complete Art. No. 2536273<br />

19“ Fiber optic patch panel 24/6LCdx/APC 8° SM 1xPG16/1xAB RAL7035 complete Art. No. 2536274

Fiber-Pigtail<br />

• Pigtails with optical <strong>fiber</strong> (600 µm acrylate buffer) and LC/APC8° connec<strong>to</strong>r<br />

Description of LC/APC simplex:<br />

• user-friendly audible latch <strong>to</strong> indicate proper mating<br />

• push-pull locking<br />

• plastic housing with zirconia ferrule<br />

• standard IEC 61754-20<br />

• insertion loss (IL) for SM (typical)<br />

mean value<br />

< 0.15 dB (<strong>to</strong> reference connec<strong>to</strong>r)<br />

max. value<br />

< 0.30 dB (<strong>to</strong> reference connec<strong>to</strong>r)<br />

• return loss (RL)<br />

> 65 dB<br />

• 8° SM-Angle (APC) polishing<br />

PT LC/APC8° 1E9/125/600/rt 1m for OTO Art. No. 2536266<br />

PT LC/APC8° 1E9/125/600/gn 1m for OTO Art. No. 2536267<br />

PT LC/APC8° 1E9/125/600/ge 1m for OTO Art. No. 2536268<br />

PT LC/APC8° 1E9/125/600/bl 1m for OTO Art. No. 2536269<br />

PT LC/APC8° 1E9/125/600/rt 2m for patch panel Art. No. 2536275<br />

PT LC/APC8° 1E9/125/600/gn 2m for patch panel Art. No. 2536276<br />

PT LC/APC8° 1E9/125/600/ge 2m for patch panel Art. No. 2536277<br />

PT LC/APC8° 1E9/125/600/bl 2m for patch panel Art. No. 2536278<br />

FTTH in-house cable, installation cable on a cardboard reel<br />

• I-VQ(ZN)H 4E9/125 FTTH in house cable preassembled with 2 LC/APC 8° connec<strong>to</strong>rs<br />

PT LC/APC8° 2E9/125/600/2800 20m excl. OTO Art. No. 2536279<br />

PT LC/APC8° 2E9/125/600/2800 30m excl. OTO Art. No. 2536280<br />

PT LC/APC8° 2E9/125/600/2800 40m excl. OTO Art. No. 2536281<br />

PT LC/APC8° 2E9/125/600/2800 50m excl. OTO Art. No. 2536282<br />

PT LC/APC8° 2E9/125/600/2800 60m excl. OTO Art. No. 2536283<br />

OPDISYS ® Fiber <strong>to</strong> <strong>the</strong> Home - Solution • 02/2016 • © by Pengg Kabel GmbH • Technische Änderungen vorbehalten<br />

27

Fiber optic cables<br />

Fiber optic passive components<br />

Fiber optic installation services<br />

Fiber <strong>to</strong> <strong>the</strong> <strong>home</strong> - <strong>solution</strong>s<br />

Telecommunication cables<br />

Railway cables<br />

Copper cable installation services<br />

PENGG KABEL GmbH<br />

Plant Optic | Breitenfeldgasse 5 | 8661 Sankt Barbara<br />

Plant Copper | Mariazellerstraße 125 | 8605 Kapfenberg<br />

Tel.: +43 3862 / 23990-0 | Fax.: +43 3862 / 23990-672<br />

info@penggkabel.at | www.penggkabel.at