MINDA informs .... - minda.de

MINDA informs .... - minda.de

MINDA informs .... - minda.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MINDA</strong> <strong>informs</strong> .... September 2011<br />

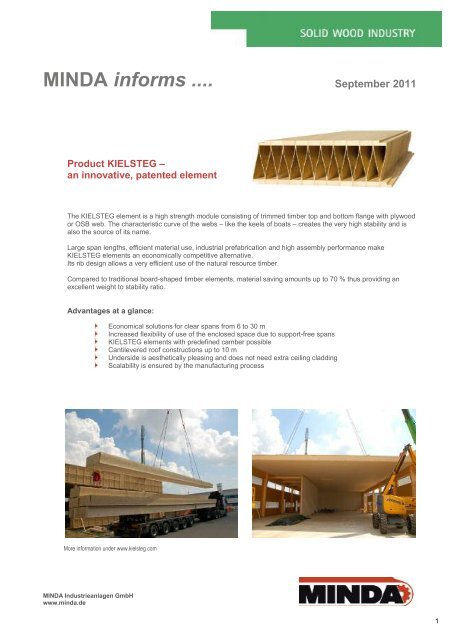

Product KIELSTEG –<br />

an innovative, patented element<br />

The KIELSTEG element is a high strength module consisting of trimmed timber top and bottom flange with plywood<br />

or OSB web. The characteristic curve of the webs – like the keels of boats – creates the very high stability and is<br />

also the source of its name.<br />

Large span lengths, efficient material use, industrial prefabrication and high assembly performance make<br />

KIELSTEG elements an economically competitive alternative.<br />

Its rib <strong>de</strong>sign allows a very efficient use of the natural resource timber.<br />

Compared to traditional board-shaped timber elements, material saving amounts up to 70 % thus providing an<br />

excellent weight to stability ratio.<br />

Advantages at a glance:<br />

<strong>MINDA</strong> Industrieanlagen GmbH<br />

www.<strong>minda</strong>.<strong>de</strong><br />

Economical solutions for clear spans from 6 to 30 m<br />

Increased flexibility of use of the enclosed space due to support-free spans<br />

KIELSTEG elements with pre<strong>de</strong>fined camber possible<br />

Cantilevered roof constructions up to 10 m<br />

Un<strong>de</strong>rsi<strong>de</strong> is aesthetically pleasing and does not need extra ceiling cladding<br />

Scalability is ensured by the manufacturing process<br />

More information un<strong>de</strong>r www.kielsteg.com<br />

O:\PR_Abteilung\Newsletter\Newsletter Holz\1_2011\<strong>MINDA</strong> <strong>informs</strong> timber 2011.doc<br />

1

2<br />

Automated production<br />

of<br />

KIELSTEG-elements<br />

Special production<br />

<strong>MINDA</strong> Industrieanlagen GmbH<br />

www.<strong>minda</strong>.<strong>de</strong><br />

features<br />

at a glance<br />

<strong>MINDA</strong> <strong>de</strong>veloped an automatic production line for<br />

KIELSTEG-elements for a wi<strong>de</strong> range of applications<br />

in the building industry. Both processes, placing of the<br />

webs and the flanges and the pressing of the<br />

KIELSTEG-elements run in automatic mo<strong>de</strong>. Also the<br />

parameters for all cross sections in heights from 228 -<br />

800 mm and lengths from 6 - 35 m are set<br />

automatically.<br />

The first plant of this type started production this year<br />

at Kulmer Holzleimbau in Pischelsdorf/Austria.<br />

automatic adjustment<br />

automatic assembly and glue application of the<br />

webs and flanges<br />

Press feeding by gantry loa<strong>de</strong>r<br />

Special press for straight and cambered elements<br />

Complete process control incl. monitoring and or<strong>de</strong>r<br />

management

Press for Kielsteg elements<br />

ADVANTAGES<br />

Press feeding by means of a gantry gripper<br />

Packages are built within the press by<br />

stacking from above<br />

Automatic alignment of the package<br />

Pressing force and lateral pressure<br />

according to the product specification<br />

Automatic discharge in longitudinal direction<br />

Process control, visualisation, or<strong>de</strong>r<br />

management and monitoring by <strong>MINDA</strong><br />

MoveIT<br />

Automatic change of dimensions<br />

automatic logging of pressing data possible<br />

SPECIAL FEATURES<br />

Optionally the press can be adjusted to a<br />

bending radius of 750 m, leading to a<br />

camber of the KIELSTEG-elements of up to<br />

wo=L/300 <strong>de</strong>pending on their lengths.<br />

Let us know your individual requirements:<br />

<strong>MINDA</strong> Industrieanlagen GmbH<br />

www.<strong>minda</strong>.<strong>de</strong><br />

O:\PR_Abteilung\Newsletter\Newsletter Holz\1_2011\<strong>MINDA</strong> <strong>informs</strong> timber 2011.doc<br />

Discharge of the finished KIELSTEG element behind the press<br />

Loading of press<br />

TECHNICAL DATA<br />

pressing length variable up to 35 m<br />

Element height 228 – 800 mm<br />

Element width approx. 1.200 mm<br />

Camber radius 750 m<br />

Performance with one press approx. 150 m² per shift<br />

<strong>MINDA</strong> – A synonym for quality!<br />

3