Outstanding biomass treatment with the QZ - MeWa Recycling ...

Outstanding biomass treatment with the QZ - MeWa Recycling ...

Outstanding biomass treatment with the QZ - MeWa Recycling ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Market & trends<br />

<strong>Outstanding</strong> <strong>biomass</strong><br />

<strong>treatment</strong> <strong>with</strong> <strong>the</strong> <strong>QZ</strong><br />

Enables gas output to rise by up to 30%<br />

S<br />

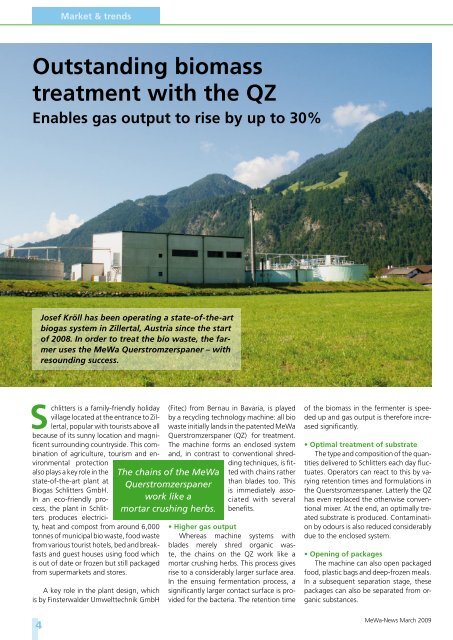

Josef Kröll has been operating a state-of-<strong>the</strong>-art<br />

biogas system in Zillertal, Austria since <strong>the</strong> start<br />

of 2008. In order to treat <strong>the</strong> bio waste, <strong>the</strong> farmer<br />

uses <strong>the</strong> <strong>MeWa</strong> Querstromzerspaner – <strong>with</strong><br />

resounding success.<br />

chlitters is a family-friendly holiday<br />

village located at <strong>the</strong> entrance to Zillertal,<br />

popular <strong>with</strong> tourists above all<br />

because of its sunny location and magnificent<br />

surrounding countryside. This combination<br />

of agriculture, tourism and environmental<br />

protection<br />

also plays a key role in <strong>the</strong><br />

state-of-<strong>the</strong>-art plant at<br />

Biogas Schlitters GmbH.<br />

In an eco-friendly process,<br />

<strong>the</strong> plant in Schlitters<br />

produces electricity,<br />

heat and compost from around 6,000<br />

tonnes of municipal bio waste, food waste<br />

from various tourist hotels, bed and breakfasts<br />

and guest houses using food which<br />

is out of date or frozen but still packaged<br />

from supermarkets and stores.<br />

A key role in <strong>the</strong> plant design, which<br />

is by Finsterwalder Umwelttechnik GmbH<br />

(Fitec) from Bernau in Bavaria, is played<br />

by a recycling technology machine: all bio<br />

waste initially lands in <strong>the</strong> patented <strong>MeWa</strong><br />

Querstromzerspaner (<strong>QZ</strong>) for <strong>treatment</strong>.<br />

The machine forms an enclosed system<br />

and, in contrast to conventional shredding<br />

techniques, is fit-<br />

The chains of <strong>the</strong> <strong>MeWa</strong><br />

Querstromzerspaner<br />

work like a<br />

mortar crushing herbs.<br />

ted <strong>with</strong> chains ra<strong>the</strong>r<br />

than blades too. This<br />

is immediately associated<br />

<strong>with</strong> several<br />

benefits.<br />

• Higher gas output<br />

Whereas machine systems <strong>with</strong><br />

blades merely shred organic waste,<br />

<strong>the</strong> chains on <strong>the</strong> <strong>QZ</strong> work like a<br />

mortar crushing herbs. This process gives<br />

rise to a considerably larger surface area.<br />

In <strong>the</strong> ensuing fermentation process, a<br />

significantly larger contact surface is provided<br />

for <strong>the</strong> bacteria. The retention time<br />

of <strong>the</strong> <strong>biomass</strong> in <strong>the</strong> fermenter is speeded<br />

up and gas output is <strong>the</strong>refore increased<br />

significantly.<br />

• Optimal <strong>treatment</strong> of substrate<br />

The type and composition of <strong>the</strong> quantities<br />

delivered to Schlitters each day fluctuates.<br />

Operators can react to this by varying<br />

retention times and formulations in<br />

<strong>the</strong> Querstsromzerspaner. Latterly <strong>the</strong> <strong>QZ</strong><br />

has even replaced <strong>the</strong> o<strong>the</strong>rwise conventional<br />

mixer. At <strong>the</strong> end, an optimally treated<br />

substrate is produced. Contamination<br />

by odours is also reduced considerably<br />

due to <strong>the</strong> enclosed system.<br />

• Opening of packages<br />

The machine can also open packaged<br />

food, plastic bags and deep-frozen meals.<br />

In a subsequent separation stage, <strong>the</strong>se<br />

packages can also be separated from organic<br />

substances.<br />

<strong>MeWa</strong>-News March 2009