The Journal of Australian Ceramics Vol 49 No 1 April 2010

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technica l: Lustre<br />

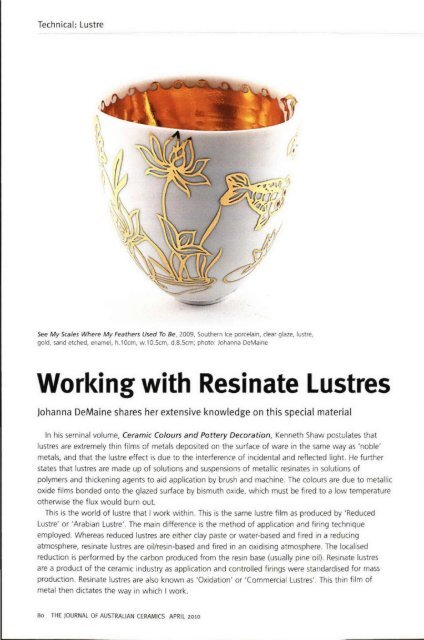

See My Scales Where My Feathers Used To Be, 2009, Southern Ice porcelain, clear glaze, lustre,<br />

gold, ",nd etched, enamel, h.1 Ocm, w.l O.Scm, d.8.5cm; photo· Johanna DeMaine<br />

Working with Resinate lustres<br />

Johanna DeMa ine shares her extensive knowledge on this special material<br />

In his seminal volume, Ceramic Colours and Pottery Decoration, Kenneth Shaw postulates that<br />

lustres are extremely th in films <strong>of</strong> metals deposited on the surface <strong>of</strong> ware in the same way as 'noble'<br />

metals, and that the lustre effect is due to the interference <strong>of</strong> incidental and reflected light. He further<br />

states that lust res are made up <strong>of</strong> solutions and suspensions <strong>of</strong> metallic resinates in solutions <strong>of</strong><br />

polymers and thickening agents to aid application by brush and machine. <strong>The</strong> colours are due to metallic<br />

oxide films bonded onto the glazed surface by bismuth oxide, which must be fired to a low temperature<br />

otherwise the flux would burn out.<br />

This is the world <strong>of</strong> lustre that I work w ithin. This is the same lustre film as produced by 'Reduced<br />

Lustre' or 'Arabian Lustre' . <strong>The</strong> main difference is the method <strong>of</strong> application and firing technique<br />

employed. Whereas reduced lustres are either clay paste or water-based and fired in a reducing<br />

atmosphere, resinate lustres are oil/resin-based and fired in an oxidising atmosphere. <strong>The</strong> localised<br />

reduction is performed by the carbon produced from the resin base (usually pine oil). Resinate lustres<br />

are a product <strong>of</strong> the ceramic industry as application and controlled firings were standardised for mass<br />

production. Resinate lustres are also known as 'Oxidation' or 'Commercial Lustres'. This th in film <strong>of</strong><br />

metal then dictates the way in which I work.<br />

80 THE JOURNAL OF AUSTRALIAN CERAMICS APRil <strong>2010</strong>