Pottery In Australia Vol 38 No 3 September 1999

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

! • The<br />

t<br />

r<br />

e<br />

e<br />

.<br />

e<br />

e<br />

.<br />

f<br />

interesting though such crystals are in themselves,<br />

has in most cases, contributed as little to the<br />

aesthetic significance of the piece as it has to the<br />

function.' Subtlety and crystalline glazed pots could<br />

be seen as contradictory. Herein lies the challenge.<br />

Technically the development of crystalline glazes<br />

depends on many variables, some of which<br />

include:<br />

colour and type of clay body: White firing,<br />

dense porcelaineous type bodies are more<br />

suited to crystalline glazes as darker bodies<br />

adversely effect the glaze colour.<br />

• The type of surface: Crystals develop differently<br />

on vertical and flat surfaces. Forms may need to<br />

be modified to suit to the glaze.<br />

• Fluid glazes: For crystal growth, the glazes need<br />

to be fluid with a viscosity which must<br />

encourage the growth of crystals. There is<br />

minimal alumina in these glazes and fluxes<br />

which promote crystal growth include zinc,<br />

odium, potassium, barium, magnesium and<br />

lithium. A fluid glaze is formed in which the<br />

oxides move freely. When cooling tarts, motion<br />

within the glaze slows down, and period bonds<br />

form as crystallites. These act as nuclei around<br />

which larger crystals may form. The slower the<br />

cooling rate the larger the crystals may be. Some<br />

oxide work better than others. Appropriate<br />

setting procedures are required for pots before<br />

all of your shelves are ruined with glazes that<br />

have run off the ware. A base-width collar and a<br />

saucer to catch glaze runoff can be useful.<br />

• Glaze application and thickness: Glazes can be<br />

brushed, dipped or sprayed, but spraying offers a more<br />

sub~:e way of varying the glaze thickness, especially<br />

towards the base of the pot.<br />

• Temperature and the length of the firing - I fire slowly<br />

up to full cone 10 in a neutral atmosphere, (60°C /hour<br />

from 1100°C to cone 10), and soak for around 10<br />

minutes to even out temperature differences within the<br />

kiln, then turn off the gas burners which are relit at<br />

1090°C. This temperature is then maintained for 3-4<br />

hours before it is shut off and closed up. The total<br />

firing time is around 15-16 hours.<br />

The temperature at which the kiln is held determines<br />

the shape of the crystals such that at 1140°C. needle<br />

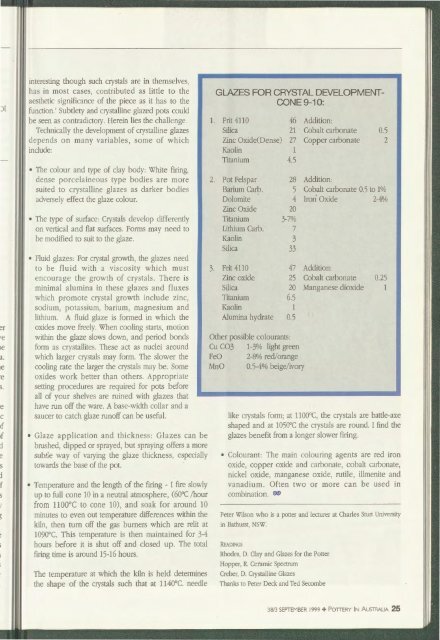

GLAZES FOR CRYSTAL DEVELOPMENT-<br />

CONE9-10:<br />

1. Frit4110 46 Addition:<br />

Silica 21 Cobalt carbonate 0.5<br />

Zinc Oxide(Dense) 27 Copper carbonate 2<br />

Kaolin 1<br />

Titanium 4.5<br />

2. Pot Felspar 28 Addition:<br />

Barium Carb. 5 Cobalt carbonate 0.5 to 1%<br />

Dolomite 4 Iron Oxide 2-4%<br />

Zinc Oxide 20<br />

Titanium 3-7%<br />

Lithium Carb.<br />

7<br />

Kaolin 3<br />

Silica 33<br />

3. Frit 4110 47 Addition:<br />

Zinc oxide 25 Cobalt carbonate 0.25<br />

Silica 20 Manganese dioxide 1<br />

Titanium 6.5<br />

Kaolin<br />

Alumina hydrate 0.5<br />

Other possible colourants:<br />

Cu C03 1-3% light green<br />

FeO 2-8% red. 1 orange<br />

MnO 0.5-4% beige, irn1y<br />

like crystals form; at 1100°C, the c1ystals are battle-axe<br />

shaped and at 1050°C the crystals are round. I find the<br />

glazes benefit from a longer slower firing.<br />

• Colourant: The main colouring agents are red iron<br />

oxide, copper oxide and carbonate, cobalt carbonate,<br />

nickel oxide, manganese oxide, rutile, illmenite and<br />

vanadium. Often two or more can be used in<br />

combination. oo<br />

Peter Wilson who is a potter and lecturer at Charles Sturt University<br />

in Bathurst, SW.<br />

READI:'\G<br />

Rhodes, D. Clay and Glazes for the Potter<br />

Hopper, R. Ceramic Spectrum<br />

Creber, D. Crystalline Glazes<br />

Thanks to Peter Deck and Ted Secombe<br />

<strong>38</strong>/3 SEPTEMBER <strong>1999</strong> + POTTERY IN AUSTRALIA 25