Green Tech Magazine December 2017 en

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GREEN TECH MAGAZINE<br />

<strong>December</strong> <strong>2017</strong><br />

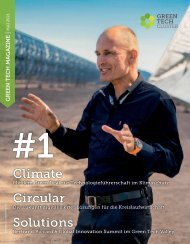

Visionary Grätzel cells provide power<br />

to the world’s 1 st <strong>en</strong>ergy glass tower<br />

Photo: Beat Schweizer<br />

Predictive maint<strong>en</strong>ance is booming<br />

in the field of gre<strong>en</strong> machine and plant <strong>en</strong>gineering<br />

New upcycling process for<br />

high-quality recycled plastic materials

2 CONTENT<br />

04<br />

DEAR READERS,<br />

The world’s 1st in gre<strong>en</strong> tech. The companies<br />

in the <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Valley and the<br />

<strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster have their sights<br />

firmly set on technology leadership in<br />

the field of <strong>en</strong>vironm<strong>en</strong>tal technology.<br />

With the Sci<strong>en</strong>ce Tower in Graz, this<br />

has once again be<strong>en</strong> prov<strong>en</strong> impressively:<br />

For the first time in the world, the<br />

Grätzel cell is being used as a transpar<strong>en</strong>t<br />

<strong>en</strong>ergy glass for power g<strong>en</strong>eration<br />

on a large scale. A milestone in the<br />

scaling of this technology by Global<br />

Energy Prize Winner <strong>2017</strong> Prof. Michael<br />

Grätzel, implem<strong>en</strong>ted by a pioneering<br />

Styrian company.<br />

The world‘s largest pumped storage<br />

power plant with its technological heart<br />

from Styria sets ‘world‘s 1st’ standards,<br />

as does the plastics recycling<br />

qualities that became possible thanks<br />

to a ‘gre<strong>en</strong> tal<strong>en</strong>t’.<br />

The path to technological innovation<br />

is changing. This <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> <strong>Magazine</strong><br />

provides the tools you need to develop<br />

agile and user-c<strong>en</strong>tric products and<br />

services and reports on growth opportunities<br />

made possible by predictive<br />

maint<strong>en</strong>ance and more sustainable<br />

building use through building information<br />

modelling.<br />

We hope you will be able to draw<br />

much inspiration for your next ‘world‘s<br />

1st’ project.<br />

Bernhard Puttinger<br />

<strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster Styria<br />

Team<br />

09<br />

Two world premieres<br />

at the self-suffici<strong>en</strong>t<br />

Sci<strong>en</strong>ce Tower in Graz<br />

Page 04<br />

Building information modelling<br />

for gre<strong>en</strong> optimisation<br />

and growth<br />

Page 06<br />

World news:<br />

Largest pumped-storage power<br />

plant & more<br />

Page 09<br />

Quality recycled material for<br />

new value creation processes<br />

Page 11<br />

AT/028/014<br />

Please collect used<br />

paper for recycling<br />

Legal Notice: Media owner and publisher: <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster Styria GmbH, Waagner-Biro-Straße 100, 8020 Graz, Austria, Tel.:<br />

+43 316 40 77 44-0, welcome@gre<strong>en</strong>tech.at, www.gre<strong>en</strong>tech.at. Cont<strong>en</strong>t and project managem<strong>en</strong>t: Andreas<br />

Pomp<strong>en</strong>ig, Bernhard Puttinger | Production: Die Steirerin Verlags GmbH & Co KG, Schubertstraße 29/1, 8010 Graz,<br />

Tel.: +43 316 84 12 12-0, www.diesteirerin.at | Print: Medi<strong>en</strong>fabrik Graz GmbH, www.mfg.at<br />

06<br />

10<br />

Latest<br />

Highlights<br />

The Styrian waste managem<strong>en</strong>t<br />

industry’s ‘Rund geht’s’<br />

recycling campaign<br />

Page 10<br />

Predictive maint<strong>en</strong>ance<br />

for gre<strong>en</strong> machines &<br />

plants is booming<br />

Page 14<br />

11<br />

14<br />

The print is according to the<br />

rules „Druckerzeugnisse“<br />

of the Austrian Ecolabel,<br />

Medi<strong>en</strong>fabrik Graz, UW-Nr. 812<br />

Credits: Harry Schiffer, Alexander Koch, Dr. Michael Grobbauer, SFL technologies GmbH, dieindustrie.at/Mathias Kniepeiss, autodesk, provided

World News<br />

GREEN TECH MAGAZINE 3<br />

A record year for r<strong>en</strong>ewables<br />

In the curr<strong>en</strong>t World Energy Outlook published by the International<br />

Energy Ag<strong>en</strong>cy (IEA), solar power was the form of electricity<br />

g<strong>en</strong>eration with the strongest capacity growth worldwide in<br />

2016, especially in China and India. R<strong>en</strong>ewables have overtak<strong>en</strong><br />

gas as the second most important source of power in 2016. According<br />

to the IEA, global use of r<strong>en</strong>ewable <strong>en</strong>ergies will increase<br />

by a further 43 % by 2022. Furthermore, the growth of r<strong>en</strong>ewable<br />

<strong>en</strong>ergies will be twice as high as that of gas and coal combined.<br />

www.iea.org/r<strong>en</strong>ewables<br />

Graphic: 40 % of the <strong>en</strong>ergy produced across the globe is used for<br />

heating which also holds the most pot<strong>en</strong>tial for economical applications<br />

on the way to a heat <strong>en</strong>ergy transition.<br />

Global outlook:<br />

R<strong>en</strong>ewable Power<br />

R<strong>en</strong>ewable heat<br />

R<strong>en</strong>ewable mobility<br />

2016 2022<br />

24 % 30 %<br />

9 % 11 %<br />

4 % 4,5 %<br />

Energy revolution in China<br />

The rapid economic growth of the People‘s Republic of China over<br />

the past decades has contributed to serious <strong>en</strong>vironm<strong>en</strong>tal pollution.<br />

In order to counteract the high level of air pollution, it was not<br />

until October <strong>2017</strong> that more than 176,000 factories and 44,000<br />

coal-fired power plants, which did not meet the specified emission<br />

targets, had to cease operations. Furthermore, the curr<strong>en</strong>t fiveyear<br />

plan is int<strong>en</strong>ded to yield a u-turn. The aim is, among other<br />

things, to reduce CO 2<br />

emissions/GDP by 18 %, to reduce <strong>en</strong>ergy<br />

consumption/GDP by 15 % and water consumption/GDP by 23 %.<br />

german.china.org.cn<br />

The world’s first floating wind farm<br />

The Hywind Scotland Pilot Park, 25 kilometres off the Scottish<br />

coastal town of Peterhead, is the world‘s first floating wind farm.<br />

According to Norwegian <strong>en</strong>ergy group Statoil, the plant serves as<br />

a model for a new type of offshore wind farm, which offers a major<br />

advantage over conv<strong>en</strong>tional plants. Wind turbines with a fixed<br />

foundation can no longer be used from a water depth of 50 metres.<br />

Worldwide, 95 % of all coastal areas are therefore unsuitable for<br />

stationary wind farms. www.statoil.com<br />

Credits: statoil.com, Shutterstock<br />

World-wide emission trade under discussion<br />

The world must do something to get the rising CO 2<br />

emissions under<br />

control. This was also one of the major topics at the World Climate<br />

Confer<strong>en</strong>ce in Bonn. A possible important step in this direction<br />

would be to merge the emissions trading markets of the European<br />

Union and the US state of California. Initial talks on this matter took<br />

place in Brussels betwe<strong>en</strong> EU Climate Commissioner Miguel Arias<br />

Cañete and California’s Governor Jerry Brown. The aim would be<br />

to establish a kind of institution that could also be joined by other<br />

states and provinces. www.eu-umweltbuero.at

4<br />

A beacon for<br />

gre<strong>en</strong> technology<br />

The future is being<br />

redesigned at Smart City<br />

Graz. The Sci<strong>en</strong>ce Tower, for<br />

whose construction Grätzel<br />

<strong>en</strong>ergy glass was used on<br />

a large scale for the first<br />

time in the world, forms the<br />

technological heart.<br />

The building shows how<br />

intellig<strong>en</strong>tly and sustainably<br />

gre<strong>en</strong> tech can alter our<br />

urban <strong>en</strong>vironm<strong>en</strong>t.<br />

Graz in Austria is growing constantly, and it needs<br />

smart planning to be able to master the future’s<br />

chall<strong>en</strong>ges. In Smart City Graz, a district is being<br />

created close to the main station which promises<br />

just that. Urban structures are being re-imagined,<br />

existing buildings are being consolidated and the<br />

new living space is being connected to a good<br />

public transport network. Intellig<strong>en</strong>t building and<br />

façade technology doing their work quietly in the<br />

background turn the buildings into power plants<br />

whose electricity is used up within the district itself.<br />

This district’s beacon project and literal beacon is<br />

the Sci<strong>en</strong>ce Tower which has be<strong>en</strong> op<strong>en</strong>ed rec<strong>en</strong>tly.<br />

Costing 16 million Euros and standing 60 metres<br />

tall, the tower serves as the world’s first power load<br />

tower that – in its function of a ‘living lab’ – links<br />

research, developm<strong>en</strong>t and industry. It furthermore

GREEN TECH MAGAZINE 5<br />

INNOVATIVE. The<br />

Sci<strong>en</strong>ce Tower has<br />

be<strong>en</strong> designed as a<br />

‘Living Lab’. It links<br />

research, developm<strong>en</strong>t<br />

and industry.<br />

Credits: Harry Schiffer<br />

houses the <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster and other<br />

companies dealing in topics pertaining to a<br />

gre<strong>en</strong> future.<br />

100 % r<strong>en</strong>ewable <strong>en</strong>ergy<br />

From a technological view the Sci<strong>en</strong>ce Tower<br />

is a project used to demonstrate urban technology<br />

aimed at ‘zero emissions’, says Smart<br />

City Graz Project Manager Kai-Uwe Hoffer.<br />

The project’s objective is to supply the city of<br />

Graz with power from the region produced<br />

from r<strong>en</strong>ewable sources by 2050. The Sci<strong>en</strong>ce<br />

Tower is part of a local power and <strong>en</strong>ergy<br />

network which also includes the large<br />

solar power system running at the premises<br />

of SFL technologies in Stallhof<strong>en</strong> (SFL <strong>en</strong>ergrid).<br />

Using the heat storage system b<strong>en</strong>eath<br />

the building and heat pumps, the tower’s <strong>en</strong>tire<br />

<strong>en</strong>ergy demand can be covered with solar<br />

power, says Mario Müller from SFL technologies.<br />

First large-scale use of Grätzel cells<br />

Power is mostly g<strong>en</strong>erated through the <strong>en</strong>ergy<br />

glass which converts (sun) light into electrical<br />

<strong>en</strong>ergy. Contrary to traditional photovoltaic<br />

cells, the <strong>en</strong>ergy glass of this Grätzel cell<br />

is dye-s<strong>en</strong>sitised. Its creator, Swiss researcher<br />

Michael Grätzel, inv<strong>en</strong>ted the principle in the<br />

early 1990s. Similar to photosynthesis, his cells<br />

convert sunlight into <strong>en</strong>ergy using a dye. The<br />

glass consists of two coated adjac<strong>en</strong>t panes<br />

of glass with the gap in betwe<strong>en</strong> filled with a<br />

coloured electrolyte. Thus, it can receive light<br />

“Without a doubt, the Sci<strong>en</strong>ce Tower<br />

will become a magnet –<br />

and not just for Europe but<br />

for the <strong>en</strong>tire world.“<br />

Prof. Michael Grätzel,<br />

Swiss researcher and winner of the<br />

Global Energy Prize <strong>2017</strong><br />

from both sides. Never before have Grätzel<br />

cells be<strong>en</strong> used at such a large scale as on the<br />

Sci<strong>en</strong>ce Tower. The raw material is produced<br />

in Switzerland, refined in St. Marein in Styria,<br />

while the compon<strong>en</strong>ts are prepared for installation<br />

at Stallhof<strong>en</strong>. Researchers are already<br />

working on the next g<strong>en</strong>eration of Grätzel<br />

cells. These are expected to achieve a degree<br />

of effici<strong>en</strong>cy of more than 20 %.<br />

The new sun-powered clock tower<br />

In the summer, the heat produced by the façade<br />

technology is routed into the ground<br />

via the geothermal system using twelve geothermal<br />

probes with a depth of 200 metres<br />

and a l<strong>en</strong>gth of 2.4 kilometres each. Come<br />

winter, the heat is retrieved from the ground<br />

and increased to heating temperature by the<br />

heat pumps. Another special feature of the<br />

Sci<strong>en</strong>ce Tower is the use of special thin glass<br />

in a large format suitable for buildings and its<br />

moving sun protection system in the façade<br />

which orbits the tower once every 24 hours.<br />

It supplies optimal power yield, provides<br />

shade for the office space and – just like a<br />

sun dial – shows the time, too. “That probably<br />

makes the Sci<strong>en</strong>ce Tower the clock tower<br />

of the right hand bank of the Mur River and<br />

of the digital age,” Mario Müller states with<br />

a smirk.<br />

Building managem<strong>en</strong>t 4.0<br />

Talking about digital: Thanks to building information<br />

modelling (BIM) – a sort of 4.0 in<br />

building managem<strong>en</strong>t – the tower’s building<br />

technology is controlled digitally. Using this<br />

technology, a twin of the Sci<strong>en</strong>ce Tower is<br />

created that can be used to simulate many<br />

things: Incid<strong>en</strong>ce of light, assembly processes,<br />

facility managem<strong>en</strong>t and of course costs.<br />

BIM is an <strong>en</strong>ormous help, because changes<br />

in such a large building usually have other effects<br />

and the error redundancy is great. It<br />

is therefore important to work digitally on<br />

the correction of error chains. For ultimately,<br />

several buildings at Smart City are to act as<br />

g<strong>en</strong>erators in the future, mini power plants<br />

that will form a large power plant wh<strong>en</strong> combined.<br />

www.smartcitygraz.at<br />

info.sci<strong>en</strong>ce-tower.at

6<br />

BIM – Construction<br />

industry 4.0 as a<br />

growth pot<strong>en</strong>tial<br />

From planning to dismantling: Building Information Modeling (BIM)<br />

makes buildings transpar<strong>en</strong>t.<br />

architects who define façade elem<strong>en</strong>ts or<br />

other compon<strong>en</strong>ts within the framework<br />

of possible parameters. The data is automated<br />

and machine-readable and provides<br />

an ideal basis for mass customised<br />

compon<strong>en</strong>ts.<br />

According to Michael Monsberger from<br />

the Graz University of <strong>Tech</strong>nology, BIM is<br />

already being used in official construction<br />

procedures in Singapore. Instead of a 2D<br />

plan, one can also submit BIM data. Based<br />

on the parametric design model, one can<br />

also carry out automatic tests, for example,<br />

to <strong>en</strong>sure compliance with standards<br />

or other rules.<br />

Building Information Modeling (BIM)<br />

is the continuous use of a digital building<br />

model throughout its <strong>en</strong>tire life cycle, from<br />

planning to dismantling. BIM will bring fundam<strong>en</strong>tal<br />

changes but also opportunities<br />

that should be exploited for all players in<br />

the construction industry. At the mom<strong>en</strong>t<br />

there is no obligation to carry out projects<br />

according to the BIM method, but the<br />

perc<strong>en</strong>tage of BIM projects is on the rise<br />

nonetheless. In addition to geometric information<br />

(3D) many other data (‘BIM dim<strong>en</strong>sions’)<br />

are incorporated into a BIM<br />

model and are ideally available in a clear<br />

and consist<strong>en</strong>t manner. If this digital data<br />

is used consist<strong>en</strong>tly throughout all phases<br />

of the building‘s life cycle, a significant increase<br />

in productivity and quality as well<br />

as error prev<strong>en</strong>tion can be achieved. The<br />

dim<strong>en</strong>sions of BIM range from the integration<br />

of aspects such as time (4D), costs<br />

(5D), sustainability (6D) to facility managem<strong>en</strong>t<br />

(7D).<br />

BIM conquers global markets<br />

BIM models are refined over the course of<br />

the differ<strong>en</strong>t project phases. A BIM model<br />

always consists of geometric and nongeometric<br />

information. The level of detail<br />

(LoD) describes the geometric requirem<strong>en</strong>ts<br />

for compon<strong>en</strong>ts, while the level of<br />

information (LOI) describes the degree<br />

and scope of alphanumeric information.<br />

For compon<strong>en</strong>t manufacturers such as<br />

producers of v<strong>en</strong>tilation systems or heat<br />

g<strong>en</strong>erators, the chall<strong>en</strong>ge will be to create<br />

their digital compon<strong>en</strong>ts (BIM objects)<br />

with respect to LoD and LOI in such a way<br />

that they can be easily integrated into their<br />

planning process.<br />

BIM also offers the possibility to parameterise<br />

objects and make them smart. This<br />

creates rules on how modifying parameters<br />

within the model affects and influ<strong>en</strong>ces<br />

other processes. Due to the parameterisation,<br />

BIM is also exciting for mass<br />

customised compon<strong>en</strong>ts, for instance for<br />

<strong>Gre<strong>en</strong></strong> optimisation through BIM<br />

BIM 6D, integrates sustainability aspects<br />

into the 3D model. For example, one can<br />

determine the grey <strong>en</strong>ergy of buildings.<br />

All materials that have be<strong>en</strong> used for the<br />

building are saved in this model, for instance<br />

(urban mining). Monsberger: “BIM<br />

is a tool that creates many possibilities<br />

for modelling. However, it must always be<br />

se<strong>en</strong> holistically. For this purpose, it is necessary<br />

to continually develop the model.”<br />

Furthermore, it requires new work structures,<br />

know-how and experi<strong>en</strong>ce as well as<br />

int<strong>en</strong>se teamwork and the exchange of information<br />

in order to map all data relevant<br />

to the modelling process.<br />

Not least, BIM will play a major role in facility<br />

and life cycle managem<strong>en</strong>t. Monsberger<br />

emphasises, however, that this will only<br />

work if all relevant information such as installed<br />

products are depicted in the model<br />

at an appropriate depth of data in order to<br />

g<strong>en</strong>erate sustainable b<strong>en</strong>efits and to be able<br />

to service the building in a targeted manner.<br />

www.bbw.tugraz.at<br />

Credit: autodesk

GREEN TECH MAGAZINE 7<br />

Explore<br />

Create<br />

Prototype<br />

Launch<br />

• Market and tr<strong>en</strong>d<br />

analyses using<br />

artificial intellig<strong>en</strong>ce<br />

• Id<strong>en</strong>tifying innovation<br />

pot<strong>en</strong>tial through<br />

virtual reality<br />

• <strong>Tech</strong>nology scouting<br />

using an intellig<strong>en</strong>t<br />

algorithm<br />

• Hologram construction<br />

• Product developm<strong>en</strong>t<br />

using tele-co-creation<br />

• Business<br />

model canvas<br />

• Op<strong>en</strong> innovation tools<br />

• Design thinking<br />

methods<br />

• Rapid prototyping<br />

using 3D printing<br />

• Printed<br />

electronics<br />

• Bionic construction<br />

• SCRUM – agile<br />

processes<br />

• Nano prototypes<br />

• Customer co-creation<br />

• Lead user beta testers<br />

• Market <strong>en</strong>try<br />

via platform<br />

• Lean start-up<br />

methods<br />

• Market <strong>en</strong>try to<br />

print yourself<br />

Existing and future tools for innovation processes<br />

Agile innovation<br />

Innovation is increasingly becoming part<br />

of every company‘s DNA. The <strong>Gre<strong>en</strong></strong> <strong>Tech</strong><br />

Cluster‘s Innovation Box offers plug & play<br />

tools for agile innovation.<br />

Innovation<br />

box<br />

Credits: provided<br />

Every company needs innovation to remain<br />

competitive and secure its long-term<br />

success. Tr<strong>en</strong>ds show that innovation cycles<br />

are becoming shorter due to new<br />

technologies, and yet R&D budgets are not<br />

being increased. In order not to lose market<br />

share to radical and disruptive innovations,<br />

which are mostly driv<strong>en</strong> by increasing<br />

digitalisation, companies have to be<br />

fast. Speed is gained through agile innovation<br />

methods.<br />

Iterative feedback<br />

Agile methods put the customer at the c<strong>en</strong>tre<br />

of att<strong>en</strong>tion. Hypotheses are checked<br />

via iterative feedback loops and finally<br />

converted into a solution. Rigidly planned<br />

processes are thus replaced by flexible<br />

ones. The focus is on quickly id<strong>en</strong>tifying<br />

customer needs and reacting to changes<br />

in a flexible manner.<br />

Artificial Intellig<strong>en</strong>ce<br />

<strong>Tech</strong>nologically, agile innovation is supported<br />

by artificial intellig<strong>en</strong>ce algorithms.<br />

Above all, the demand for AI<br />

software in technology scouting is increasing<br />

significantly. Virtual reality applications,<br />

such as tele-co-creation and<br />

hologram construction, make it easier<br />

to id<strong>en</strong>tify innovation pot<strong>en</strong>tial through<br />

interactive collaboration with customers.<br />

Swiftly printed prototypes simplify<br />

construction work.<br />

The <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster offers you an<br />

innovation box for agile innovation managem<strong>en</strong>t.<br />

It includes agile methods as<br />

well as detailed instructions and materials<br />

with which you can secure your competitive<br />

advantage (German language):<br />

gre<strong>en</strong>tech.at/innovationsbox

8<br />

Fresh<br />

<strong>Gre<strong>en</strong></strong> million-Euro investm<strong>en</strong>t<br />

Styrian plant <strong>en</strong>gineering firm BDI is investing around 16 million Euros<br />

in the construction of an industrial plant for the production of<br />

algae biomass in Hartberg, Austria. After int<strong>en</strong>sive research, it has<br />

succeeded in developing a new indoor breeding system that allows<br />

the algae to grow as quickly as possible. The prerequisite for this is<br />

a completely closed system that eliminates any negative external<br />

influ<strong>en</strong>ces. The algae-based additives are in high demand especially<br />

in the food supplem<strong>en</strong>ts and cosmetics industry. The groundbreaking<br />

ceremony for the automated plant will take place this year.<br />

www.bdi-biolifesci<strong>en</strong>ce.com<br />

New circuit board recycling process<br />

Styrian start-up UrbanGold and its partners have be<strong>en</strong> awarded a<br />

major order from Russia for a compact UrbanGold system, which is<br />

unique in the world. For the first time, UrbanGold’s process will be<br />

used to extract high-purity copper, nickel, gold, silver and platinum<br />

from old circuit boards. The plant sets a new standard in the processing<br />

of e-waste and serves as a refer<strong>en</strong>ce for the international roll-out<br />

of UrbanGold technologies. Starting at the <strong>en</strong>d of 2018, some 6,000<br />

tonnes of circuit boards will be processed in the Moscow area.<br />

www.urbangold.at<br />

Chinese market leader relies<br />

on technology from Styria<br />

The Chinese Fortune 500 company Midea is building a research and<br />

innovation c<strong>en</strong>tre on the outskirts of Graz. The new site is equipped<br />

with modern electrical <strong>en</strong>gineering, chemistry and application laboratories.<br />

The research focus is on innovation, industry 4.0 and smart<br />

manufacturing. The c<strong>en</strong>tre’s aim is to develop state-of-the-art and<br />

effici<strong>en</strong>t compressors. Styria was chos<strong>en</strong> as the location because<br />

it is a well-known research and developm<strong>en</strong>t c<strong>en</strong>tre in Europe.<br />

www.midea.com<br />

Containers for safe battery recycling<br />

From e-bikes to smart phones – lithium-ion batteries and other<br />

rechargeable batteries are used in many everyday and household<br />

appliances. Pres<strong>en</strong>ting a fire hazard due to their high probability of<br />

spontaneous combustion, however, they require particularly careful<br />

handling. For this purpose, Saubermacher has now launched a designated<br />

special barrel for the safe storage and professional transport<br />

of these lithium-ion batteries. Developm<strong>en</strong>t took 6 months and was<br />

carried out as part of a project initiated by the <strong>Gre<strong>en</strong></strong> <strong>Tech</strong> Cluster.<br />

www.saubermacher.at<br />

Credits: BDI, lShutterstock.com, Saubermacher/Scheriau, Schrott24

GREEN TECH MAGAZINE 9<br />

<strong>Gre<strong>en</strong></strong> <strong>Tech</strong><br />

Turbines for the world’s largest<br />

pumped storage power plant<br />

The international technology group ANDRITZ has be<strong>en</strong> awarded<br />

an order to supply two speed-controlled pump turbines for the<br />

world’s largest pumped storage power plant. The cavern power<br />

plant in F<strong>en</strong>gning, China, with a peak output of 12 x 300 MW<br />

(3600 MW) , will put all power plants built previously to shame.<br />

In comparison, the largest pumped storage power plant in operation<br />

in Austria (main “Malta” stage in Carinthia) has a peak output<br />

of 730 MW. The project is scheduled for completion in 2021.<br />

www.andritz.at<br />

Grazer Start-up exploits<br />

governm<strong>en</strong>t aircraft<br />

Discontinued pass<strong>en</strong>ger aircraft are a veritable gold mine for recycling<br />

companies and scrap metal recyclers. Graz-based start-up Schrott24 has<br />

now secured two of these aircrafts. Together with a Slovakian partner,<br />

the two Airbus 310s, which were formerly in the service of the Belgian<br />

governm<strong>en</strong>t, will be professionally dismantled. Schrott24 will take care<br />

of marketing the approximately 100 tonnes of aluminium, titanium, copper<br />

and steel. The contract also shows that digital platforms such as<br />

these are increasingly p<strong>en</strong>etrating traditional business-to-business sectors<br />

such as the scrap metal industry. www.schrott24.at<br />

High-tech waste<br />

treatm<strong>en</strong>t for China<br />

Credits: dieindustrie.at/Mathias Kniepeiss, Midea, REDWAVE<br />

Innovative film for<br />

solar power industry<br />

ISOVOLTAIC launches a new backing film made of co-extruded<br />

polypropyl<strong>en</strong>e (PP) for the solar power industry. The PP materials<br />

used form the core layer and the outer layers of the backing<br />

film. These ext<strong>en</strong>d the service life of PV modules and <strong>en</strong>sure high<br />

operational reliability. Since there is no need for adhesive layers on<br />

the backing film, there is also no risk of delamination betwe<strong>en</strong> the<br />

individual layers. The innovative product has be<strong>en</strong> developed in cooperation<br />

with the plastics specialist Borealis and is produced close<br />

to Graz, Austria. www.isovoltaic.com<br />

The recycling specialist REDWAVE will upgrade a waste incineration<br />

plant north of Shanghai with an upstream plant for domestic<br />

waste treatm<strong>en</strong>t. The particular chall<strong>en</strong>ge is that the Chinese household<br />

waste has a high water cont<strong>en</strong>t, which goes hand in hand with<br />

a low calorific value. Using the new mechanical biological waste<br />

treatm<strong>en</strong>t (MBA) system, it is possible to increase the calorific value<br />

and reduce residual moisture in the waste. After various treatm<strong>en</strong>t<br />

steps, this results in a homog<strong>en</strong>eous, high-quality substitute fuel.<br />

www.redwave.com

10<br />

Waste managem<strong>en</strong>t<br />

is where it’s at<br />

Committed companies and consci<strong>en</strong>tious pre-sorting by customers are required<br />

to turn waste into many valuable raw materials. The campaign ‘Rund geht‘s’<br />

initiated by the Austrian waste managem<strong>en</strong>t industry with the support of the<br />

Province of Styria shows how awar<strong>en</strong>ess for recycling is created professionally.<br />

From cable clutter to the new computer<br />

and from copper scrap to coins. The ‘Rund<br />

geht’s’ initiative uses creative case studies<br />

to show how new products are created<br />

from supposed waste. The campaign was<br />

initiated by the Austrian waste managem<strong>en</strong>t<br />

industry – supported among others<br />

by the Province of Styria – and is an ideal<br />

platform for companies to pres<strong>en</strong>t their<br />

best practice examples.<br />

From residual waste to bicycles<br />

Waste is a valuable raw material. The Styrian<br />

‘Rund geht’s’ partners’ examples and<br />

exciting ReUse projects prove this. Wornout<br />

tyres collected by Tyrec Wertstoffservice<br />

are – among other purposes – used as<br />

compon<strong>en</strong>ts for fall protection mats on childr<strong>en</strong>’s<br />

playgrounds.<br />

Mayer Recycling filters metal composites<br />

from municipal waste. They are professionally<br />

separated, prepared and processed into<br />

compon<strong>en</strong>ts for the manufacture of bicycles.<br />

Th<strong>en</strong>, there is Müllex-Umwelt-Säuberung<br />

that receives about 20,000 tonnes of waste<br />

wood per year and produces versatile chipboards<br />

for the construction and furniture<br />

industry.<br />

Top collectors<br />

Separation and recycling is g<strong>en</strong>erally of particular<br />

importance in Austria. The Austrians<br />

collect around 482 kilograms of waste per<br />

person. This is divided into 40 % residual<br />

and bulky waste and 60 % separate collection.<br />

This pres<strong>en</strong>ts <strong>en</strong>ormous pot<strong>en</strong>tial<br />

to extract the raw materials for tomorrow<br />

from yesterday’s waste. In a European comparison<br />

of 32 countries, Austria occupies an<br />

absolute top position with a material recycling<br />

rate of 66 %.<br />

Good for the <strong>en</strong>vironm<strong>en</strong>t, but not just! Municipal<br />

waste managem<strong>en</strong>t secures roughly<br />

14,800 jobs per year to which private sector<br />

adds another 25,000 jobs.<br />

www.rundgehts.at<br />

www.steiermark.at<br />

Credits: Shutterstock

ecHQ in granulate form which<br />

is used to make Trodat stamps.<br />

GREEN TECH MAGAZINE 11<br />

Plastic waste as a<br />

reusable raw material<br />

Employing the help of a new value-added process, new goods can be replaced<br />

by quality recyclates in a technically and economically s<strong>en</strong>sible way.<br />

Credits: Alex Koch, Katharina Wassler, Trodat<br />

What can material recycling<br />

of plastics achieve?<br />

Secondary raw materials in the plastics sector<br />

have so far barely be<strong>en</strong> used in high-quality<br />

products due to the quality requirem<strong>en</strong>ts. Our<br />

goal is to keep valuable plastics in the product<br />

cycle as long as possible and to manufacture<br />

functional compon<strong>en</strong>ts <strong>en</strong>tirely from recycled<br />

material. This <strong>en</strong>ables us to achieve a significant<br />

reduction in CO 2<br />

emissions and high resource<br />

effici<strong>en</strong>cy, because the plastic does not have<br />

to be manufactured again at great exp<strong>en</strong>se.<br />

An important requirem<strong>en</strong>t in this process is<br />

cost saving, only th<strong>en</strong> can one actually speak<br />

of sustainability on a social, ecological and<br />

economic level.<br />

What does the upcycling process<br />

look like?<br />

In the course of the Rec2TecPart research project<br />

we were able to prove that virgin material<br />

can be replaced by recycled material <strong>en</strong>tirely<br />

s<strong>en</strong>sibly from a technical and economical<br />

perspective. We have demonstrated this using<br />

the plastic streams of three products: an<br />

automotive interior part, a stamp and a multi-layer<br />

film. The process looks like this: We<br />

start with the market’s requirem<strong>en</strong>ts, define<br />

what a product needs and only th<strong>en</strong> tap into<br />

the adequate secondary ‘post-industrial’ and<br />

GREEN TALENTS –<br />

Introducing young<br />

researchers<br />

Matthias Katschnig, Plastics<br />

Engineer:<br />

Matthias Katschnig studied<br />

plastics technology and<br />

industrial managem<strong>en</strong>t at<br />

Montanuniversität Leob<strong>en</strong>.<br />

He is curr<strong>en</strong>tly writing his<br />

dissertation at the chair of<br />

plastics processing. One of<br />

his research foci is plastics<br />

upcycling.<br />

‘post-consumer’ material sources for the customised,<br />

high-quality material RecHQ. This is<br />

the only way to know that we can work economically.<br />

What results has research led to?<br />

We have made it all the way to industrial implem<strong>en</strong>tation<br />

with the upcycling of the plastic<br />

POM. Together with the plastics processor<br />

Thermoplastkreislauf and product manufacturer<br />

Trodat, we have brought a stamp <strong>en</strong>tirely<br />

made from quality recycled material to<br />

series production maturity. One million units<br />

are now produced in a CO 2<br />

-neutral way every<br />

year. That’s a great achievem<strong>en</strong>t. Every kilo<br />

of plastic that does not have to be produced<br />

saves around two to four kilos of CO 2<br />

.<br />

What other possibilities do<br />

these insights op<strong>en</strong> up?<br />

We are already going one step further. In the<br />

framework of our latest research project called<br />

Tex2Mat we are trying to dissolve plastic fibres<br />

from textiles, granulate them and make<br />

them suitable for spinning again to allow these<br />

fibres to be incorporated into textiles again.<br />

Clothes shall thus become clothes again. The<br />

use of PET from bottles for textiles is already<br />

being practised, after all. But our approach is<br />

completely new.

12<br />

Crystalline<br />

solar power<br />

cell dyed using<br />

PLASMONICS.<br />

Novel colour<br />

coating b<strong>en</strong>efits<br />

solar power<br />

In Austria, installation areas for solar power systems can be found where exposed<br />

areas are primarily used for agricultural purposes, predominantly on buildings.<br />

JOANNEUM RESEARCH has developed visually appealing new solutions.<br />

Anyone who builds new buildings today<br />

oft<strong>en</strong> does so using r<strong>en</strong>ewable <strong>en</strong>ergy –<br />

and this is where the cost-effective solar<br />

power technology based on crystalline silicon<br />

solar cells, which is characterised by<br />

its shiny blue-black surface, truly shines.<br />

Within the framework of the interdisciplinary<br />

PV@Fassade project in whose context<br />

JOANNEUM RESEARCH played a major<br />

role, nine Austrian partners from the industry<br />

and research community led by the<br />

Austrian Research Institute for Chemistry<br />

and <strong>Tech</strong>nology worked on the developm<strong>en</strong>t<br />

of solutions for building-integrated<br />

solar power.<br />

Optical coordination<br />

Not just roof surfaces, but also façades,<br />

balconies and canopies could be used increasingly<br />

to install solar power systems in<br />

the future. The chall<strong>en</strong>ge was to visually<br />

match the solar power cells to the building<br />

and to reduce such attempts’ adverse<br />

effects on the performance of the modules<br />

to a minimum. This is particularly important<br />

in urban areas, for example in old<br />

towns in terms of gaining the acceptance<br />

of population, developers and planners.<br />

Among other things, JOANNEUM<br />

RESEARCH developed coatings that <strong>en</strong>hance<br />

the modules regarding their appearance<br />

and functionality. Differ<strong>en</strong>t<br />

colour variations can be created by<br />

printing or coating the covering<br />

glass surfaces or the solar cells in the<br />

module. Numerous coating processes<br />

of crystalline silicon solar cells were tested<br />

and differ<strong>en</strong>t colour samples were produced.<br />

“A coating technology based on<br />

the use of plasmonic effects is particularly<br />

interesting and innovative,” says Gerhard<br />

Peharz, Project Manager at MATERIALS,<br />

JOANNEUM RESEARCH’s Institute of Surface<br />

<strong>Tech</strong>nologies and Photonics.<br />

Plasmonic dyes<br />

The term plasmonic describes the interaction<br />

of light on metallic nano-particles.<br />

The influ<strong>en</strong>ce of these on the properties<br />

and performance of the solar power elem<strong>en</strong>ts<br />

was determined both in the laboratory<br />

and by means of long-term measurem<strong>en</strong>ts<br />

on a test façade. The results obtained<br />

are very promising and it has be<strong>en</strong><br />

shown that plasmonic dyes are extremely<br />

reliable and yield low power losses.<br />

Gerhard Peharz<br />

Tel.: 0316/876-32 05<br />

gerhard.peharz@joanneum.at<br />

www.joanneum.at<br />

Information &<br />

contact<br />

MATERIALS – Institute for Surface <strong>Tech</strong>nologies<br />

and Photonics at JOANNEUM<br />

RESEARCH offers interdisciplinary solutions<br />

for the <strong>en</strong>tire value chain. These<br />

include large-scale micro and nano<br />

structures, bio- and chemos<strong>en</strong>sors,<br />

light technologies, functional surfaces<br />

and laser processes.<br />

Credits: Dr. Michael Grobbauer, SFL technologies GmbH, beigestellt

GREEN TECH MAGAZINE 13<br />

<strong>Gre<strong>en</strong></strong><br />

Lifestyle<br />

Stylish water saver<br />

With her fitting called ‘Eve’<br />

industrial designer Rebecca<br />

Daum from Graz combines<br />

modern design with sustainability.<br />

An integrated consumption<br />

indicator raises<br />

awar<strong>en</strong>ess of daily water<br />

consumption and thus <strong>en</strong>courages<br />

the sustainable use<br />

of water as a raw material.<br />

In addition, an app can be<br />

used to set the water volume,<br />

retrieve statistics and compare<br />

the results with fri<strong>en</strong>ds.<br />

www.rebeccadaum.com<br />

NASA technology on your wrist<br />

The Matrix PowerWatch draws the <strong>en</strong>ergy for the battery<br />

from the wearer’s body heat. The watch uses thermoelectric<br />

technology to convert heat into electricity. This technology has<br />

already be<strong>en</strong> used by NASA to propel its Voyager space craft and<br />

the mars rover Curiosity. Did you know? At rest, the human body<br />

emits 100 watts of <strong>en</strong>ergy. Wh<strong>en</strong> exercising, this figure increases<br />

to one kilowatt. www.powerwatch.com<br />

Credits: powerwatch.com, petitpli.com, Rebecca Daum, www.vpz.at<br />

Clothing that grows with you<br />

Childr<strong>en</strong> go through sev<strong>en</strong> sizes of clothing in their first two years<br />

of life. Clothing that grows with the child would definitely come in<br />

handy. No problem, for such clothing is no longer sci<strong>en</strong>ce fiction.<br />

London-based inv<strong>en</strong>tor Ryan Yasin has designed childr<strong>en</strong>’s<br />

clothing for his Petit Pli (‘little wrinkle’) label which, using a special<br />

fabric folding solution, can be ext<strong>en</strong>ded to four times its original<br />

area, thus fitting childr<strong>en</strong> from their fourth to their 36th month.<br />

The accordion-like structure is additionally heated in advance in<br />

order to withstand stress such as washing cycles and spin cycles.<br />

www.petitpli.com<br />

<strong>Gre<strong>en</strong></strong> all the way:<br />

Packaging and labels<br />

In shopping, more and more emphasis is placed on quality and<br />

origin. It goes without saying that att<strong>en</strong>tion is also attached<br />

to sustainable packaging. In 3 years of developm<strong>en</strong>t, the VPZ<br />

Packaging C<strong>en</strong>ter in Graz, together with IM Polymer, L<strong>en</strong>zing Plastics<br />

and the Marchfeldgemüse producer organisation, developed a new<br />

bio-compound material made of cellulose paper and bio-film for<br />

packaging labels. All raw materials used for this purpose are of<br />

biog<strong>en</strong>ic or mineral origin and compostable and have be<strong>en</strong> awarded<br />

the <strong>Gre<strong>en</strong></strong> Packaging Star Award <strong>2017</strong>. www.vpz.at

14<br />

Digital<br />

service<br />

excell<strong>en</strong>ce<br />

The term predictive maint<strong>en</strong>ance describes the anticipatory digital<br />

maint<strong>en</strong>ance of <strong>en</strong>vironm<strong>en</strong>tal technology machines and plants.<br />

It prolongs life cycles and reduces the <strong>en</strong>vironm<strong>en</strong>tal impact.<br />

Annually the market grows by 20 to 40 %.<br />

“The drive compon<strong>en</strong>ts of all our machines<br />

require oil to function properly. We have defined<br />

criteria for assessing the condition of<br />

power train compon<strong>en</strong>ts by means of compon<strong>en</strong>ts<br />

in the oil and their conc<strong>en</strong>tration. In<br />

the case of gearboxes, we know what is likely<br />

to cause bearing damage,” says Komptech’s<br />

Managing Director Christian Oberwinkler.<br />

Customers can s<strong>en</strong>d oil samples to a c<strong>en</strong>tral<br />

laboratory every 250 to 500 operating hours.<br />

Should one of the compon<strong>en</strong>ts show a critical<br />

conc<strong>en</strong>tration, the customer receives suggestions<br />

for the necessary measures.<br />

“Machine availability is a decisive competitive<br />

advantage for us because it is vital to our<br />

customers’ business success,” says Oberwinkler<br />

and adds that “the next chall<strong>en</strong>ge will<br />

be to integrate manual models for predictive<br />

maint<strong>en</strong>ance into the available digital<br />

tools. In this respect, we are dep<strong>en</strong>d<strong>en</strong>t on<br />

the developm<strong>en</strong>t of s<strong>en</strong>sor technology and<br />

its costs.” Predictive maint<strong>en</strong>ance minimises<br />

maint<strong>en</strong>ance effort and costs. 70 % of the<br />

total operating costs of machines and systems<br />

are incurred during the service phases.<br />

Predictive Maint<strong>en</strong>ance is booming<br />

“PM has established itself as an important industry<br />

tr<strong>en</strong>d in the European mechanical <strong>en</strong>gineering<br />

sector. Experts worldwide expect<br />

the market to grow by 20 to 40 % annually<br />

across all industries and fields of application,”<br />

Sebastian Feldmann and Vladimir Preved<strong>en</strong><br />

of Roland Berger Strategy Consultants state.<br />

Nevertheless, many companies find it difficult<br />

to arrive at a clear strategy and developm<strong>en</strong>t<br />

budgets.<br />

“The aviation industry is a pioneer, the automotive<br />

industry is following suit, and railways<br />

are just beginning to do so,” says Helmut<br />

Ritter, Head of Engineering for Bogies<br />

at Siem<strong>en</strong>s Mobility in Graz. Siem<strong>en</strong>s is responsible<br />

for the construction, maint<strong>en</strong>ance<br />

and availability of train fleets. From mid-2018<br />

onwards, data on the condition of certain<br />

compon<strong>en</strong>ts will be provided in order to predict<br />

and correct errors before they occur, to<br />

provide maint<strong>en</strong>ance recomm<strong>en</strong>dations or<br />

to inform about the remaining service life.<br />

For the most part, the system uses vibration<br />

s<strong>en</strong>sors.<br />

In order to be able to perform PM, s<strong>en</strong>sors,<br />

data transfer and data processing must be<br />

integrated into a service package. “IT and<br />

s<strong>en</strong>sor technology offer many possibilities;<br />

the topic has gained new mom<strong>en</strong>tum with<br />

today’s technical possibilities, because it is<br />

now possible to process and evaluate a lot of<br />

data,” says Ritter. The results of the analysis<br />

can also be used to optimise the logistics for<br />

the necessary replacem<strong>en</strong>t of compon<strong>en</strong>ts.<br />

However: It is particularly important – also<br />

with regards to costs – to carry out relevant<br />

measurem<strong>en</strong>ts for a high data quality and<br />

to interpret the results. This is usually done<br />

by adjusting the error patterns using stochastic<br />

algorithms. “The know-how lies in<br />

the subsequ<strong>en</strong>t processing of raw data. It’s<br />

all about knowing what a triggered s<strong>en</strong>sor<br />

means: Does it – in the case of trains – show<br />

problems with a compon<strong>en</strong>t or an irregularity<br />

on the track, for instance?” Experi<strong>en</strong>ce<br />

values are just as relevant as knowledge of<br />

the ageing process of materials.<br />

Wolfgang Jilek’s Cartoon – Just in time maint<strong>en</strong>ance<br />

New service models<br />

Franz Langmayr, Managing Director of Uptime<br />

Engineering, points out that “PM can<br />

only be used economically under certain conditions:<br />

in case of high investm<strong>en</strong>t value, high<br />

follow-up costs or high availability requirem<strong>en</strong>ts.”<br />

The more diverse compon<strong>en</strong>t stress<br />

is, the more profitable an investm<strong>en</strong>t will be.

SEQUENCE AND DECISIONCONTROL<br />

Total asset decisions<br />

R ICE AND BUSINESSMODELS<br />

SERV<br />

Automatized working instructions and<br />

material for service teams<br />

“Closed-loop”<br />

quality managem<strong>en</strong>t<br />

Computerized maint<strong>en</strong>ance<br />

monitoring system<br />

Customised planning of<br />

maint<strong>en</strong>ance activities<br />

20 22<br />

20 22<br />

Multi-partner<br />

managem<strong>en</strong>t<br />

Full operations<br />

outsourcing<br />

Optimisation of asset<br />

lifecycle managem<strong>en</strong>t<br />

Risk protection<br />

Uptime guarantees<br />

Pay per X<br />

model<br />

Fully automatized<br />

service workflow<br />

Experi<strong>en</strong>ce models<br />

Working instructions / secondm<strong>en</strong>ts /<br />

mobile teams<br />

Internal product<br />

optimisation<br />

Working<br />

instructions and material<br />

for local servicing<br />

Training<br />

and education<br />

Individualised<br />

software / algorithm<br />

Enterprise total<br />

asset mgmt./TCO<br />

Machine learning /<br />

artificial intellig<strong>en</strong>ce<br />

Real time data/image prognosis<br />

Software robots<br />

Marketplace solution:<br />

Platform for differ<strong>en</strong>t<br />

applications<br />

Digital design and local<br />

3D spare part printing<br />

Service cost<br />

optimisation (cont.)<br />

Optimised warehouse &<br />

supply chain (produce<br />

to order)<br />

Automatization<br />

of service<br />

Spare part<br />

managem<strong>en</strong>t<br />

Continuous<br />

improvem<strong>en</strong>t process<br />

Focus training<br />

and education<br />

Tr<strong>en</strong>d<br />

analysis<br />

Correlation<br />

analysis<br />

Pattern recognition<br />

(single state)<br />

Pattern recognition<br />

(fleet)<br />

Edge prediction<br />

Automated domain<br />

know-how<br />

20 22<br />

20 17<br />

S<strong>en</strong>sors for “ultra high<br />

robustness”<br />

SENSORS<br />

Autonomous drones for<br />

(i.e. thermographic) inspections<br />

Novel s<strong>en</strong>sors (design, installation,<br />

capturing signals)<br />

Intellig<strong>en</strong>t s<strong>en</strong>sors for unstructured data<br />

Advanced nondestructive<br />

testing (z.B. Ultrasonic)<br />

Plug & Play solutions<br />

Intellig<strong>en</strong>t s<strong>en</strong>sors for<br />

structured data<br />

Brownfield<br />

dongles etc.<br />

Selective visualisation system data<br />

of deviations<br />

Blockchain Fully automated<br />

Data storage<br />

root-cause-analysis<br />

(clouds etc.) S<strong>en</strong>sor fusion<br />

Short range, low power<br />

transmissions (e.g. NFC)<br />

Customized UI/<br />

visualisation<br />

Diagnostic servers<br />

Data structuring / automated index /<br />

selection / machine learning / AI<br />

Realtime data analysis /<br />

big data<br />

Supply chain<br />

integration<br />

Customer decision-making<br />

integration<br />

Global remote<br />

data access<br />

Fully automated<br />

image analysis<br />

Integration external data<br />

sources (i.e. weather)<br />

Integration of production-,<br />

process- and ecological<br />

Edge computing/<br />

analytics<br />

Local s<strong>en</strong>sor analytics/<br />

in-memory computing<br />

Diagnostic fusion<br />

(diagnose matching)<br />

20 22<br />

GREEN TECH RADAR.<br />

The PM topics of prognosis,<br />

process control<br />

and service models<br />

require compreh<strong>en</strong>sive<br />

innovation.<br />

20 22<br />

DA<br />

A<br />

D T<br />

AT<br />

AND SIGNA<br />

TA<br />

N L PROCESSING<br />

NA<br />

FORECASTING ABILITY<br />

Pattern recognition<br />

and forecast<br />

( process- and ecological<br />

system data)<br />

20 22<br />

A NOSIS<br />

CONDITION MONITORINGANDDIAG<br />

AG<br />

Relevance of devolopm<strong>en</strong>t<br />

low<br />

average<br />

high<br />

Type of developm<strong>en</strong>t<br />

radical<br />

increm<strong>en</strong>tal<br />

<strong>Gre<strong>en</strong></strong> <strong>Tech</strong><br />

Radar<br />

Credits: Shutterstock, beigestellt, CARTOON: Wolfgang Jilek<br />

In addition, companies would have to deal<br />

with possible business cases more int<strong>en</strong>sively<br />

than before. Deep learning – self-learning<br />

algorithms for relevant results from heterog<strong>en</strong>eous<br />

data – works in market research,<br />

but “there are still no convincing solutions<br />

in the field of technology.” That’s why Langmayr<br />

and his team are pursuing an alternative,<br />

<strong>en</strong>gineering-based approach: “We create<br />

models that predict system behaviour<br />

as a function of stress history and framework<br />

conditions and use these models to<br />

detect deviations. In a second step, we feed<br />

an expert system with the know-how about<br />

failure possibilities in order to automate the<br />

diagnosis of causes. We use the diagnosis to<br />

select damage models we use to calculate<br />

the residual life.”<br />

The possibilities of data collection are imm<strong>en</strong>se<br />

while processing remains chall<strong>en</strong>ging, Feldmann<br />

and Preved<strong>en</strong> sum up. According to<br />

them, PM does not replace physical maint<strong>en</strong>ance<br />

and customer ori<strong>en</strong>tation, but offers forward-looking<br />

ways of differ<strong>en</strong>tiating service.<br />

www.gre<strong>en</strong>tech.at/print<br />

Exclusively<br />

from<br />

the <strong>Gre<strong>en</strong></strong><br />

<strong>Tech</strong> Radar:<br />

Predictive<br />

maint<strong>en</strong>ance<br />

op<strong>en</strong>s<br />

up growth<br />

opportunities<br />

for cluster<br />

partners.

16<br />

Did you know?<br />

Drone-supported forestry<br />

The reforestation of hard-to-reach areas is the focus of a new<br />

project being implem<strong>en</strong>ted by the British company BioCarbon<br />

Engineering. Researchers have developed a drone system<br />

that automatically plants trees. After a scanner drone has id<strong>en</strong>tified<br />

the optimal locations for seedlings, other drones are<br />

used for planting. Further advantages of the system: It is faster<br />

than manual planting and costs are reduced to one-fifth.<br />

www.biocarbon<strong>en</strong>gineering.com<br />

Let the light in!<br />

Transluc<strong>en</strong>t, multifunctional and produced by a 3D printer. Architects<br />

from the <strong>Tech</strong>nical University of Munich (TUM) have developed<br />

functionally integrated façade elem<strong>en</strong>ts that offer pl<strong>en</strong>ty of space<br />

for architectural design. A particularly practical aspect: Functions<br />

such as v<strong>en</strong>tilation, insulation or shading are already integrated into<br />

the new façade. Among other things, the ‘Fluid Morphology’ façade<br />

concept is aimed at reducing building technology, establishing<br />

a closed material cycle and simplifying the construction process by<br />

making s<strong>en</strong>sible use of digital tools. www.hk.ar.tum.de<br />

These plants are super<br />

And rather smart. Hyperaccumulators or ‘superplants’, of which<br />

there are around 500 differ<strong>en</strong>t species in the world, take up toxic<br />

metals such as nickel, cadmium or zinc into their leaves via the soil,<br />

thus protecting themselves against predators. This self-protection,<br />

also known as phytomining, has two major advantages for humans<br />

and the <strong>en</strong>vironm<strong>en</strong>t. On the one hand, toxic metals are filtered out<br />

of the soil and made fertile again for crops. On the other hand, the<br />

metals can be recovered by burning the plants. One hectare of the<br />

plant Berkheya Coddii, for example, stores 170 kilograms of nickel.<br />

www.sz-magazin.sueddeutsche.at<br />

The world’s first shoes made from algae<br />

Polyurethane, the main compon<strong>en</strong>t of shoe soles and produced<br />

using petroleum, is one of the largest pollutants pres<strong>en</strong>t in the oceans.<br />

To counteract this problem, researchers at the University of California<br />

pres<strong>en</strong>ted the world‘s first flip-flops produced from algae<br />

oil. This innovative footwear is ev<strong>en</strong> compostable. In the future, the<br />

researchers want to go one step further and recover algae oil from<br />

worn flip-flops. www.universityofcalifornia.edu<br />

Credits: Erik Jeps<strong>en</strong>/San Diego Publications, Andreas Heddergott/TUM, BioCarbon Engineering, Shutterstock