You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CASE study<br />

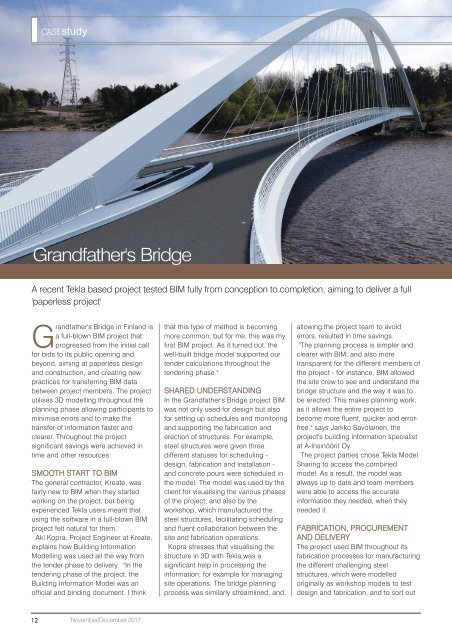

Grandfather's Bridge<br />

A recent Tekla based project tested BIM fully from conception to completion, aiming to deliver a full<br />

'paperless project'<br />

Grandfather's Bridge in Finland is<br />

a full-blown BIM project that<br />

progressed from the initial call<br />

for bids to its public opening and<br />

beyond, aiming at paperless design<br />

and construction, and creating new<br />

practices for transferring BIM data<br />

between project members. The project<br />

utilises 3D modelling throughout the<br />

planning phase allowing participants to<br />

minimise errors and to make the<br />

transfer of information faster and<br />

clearer. Throughout the project<br />

significant savings were achieved in<br />

time and other resources.<br />

SMOOTH START TO BIM<br />

The general contractor, Kreate, was<br />

fairly new to BIM when they started<br />

working on the project, but being<br />

experienced Tekla users meant that<br />

using the software in a full-blown BIM<br />

project felt natural for them.<br />

Aki Kopra, Project Engineer at Kreate,<br />

explains how Building Information<br />

Modelling was used all the way from<br />

the tender phase to delivery. "In the<br />

tendering phase of the project, the<br />

Building Information Model was an<br />

official and binding document. I think<br />

that this type of method is becoming<br />

more common, but for me, this was my<br />

first BIM project. As it turned out, the<br />

well-built bridge model supported our<br />

tender calculations throughout the<br />

tendering phase."<br />

SHARED UNDERSTANDING<br />

In the Grandfather's Bridge project BIM<br />

was not only used for design but also<br />

for setting up schedules and monitoring<br />

and supporting the fabrication and<br />

erection of structures. For example,<br />

steel structures were given three<br />

different statuses for scheduling -<br />

design, fabrication and installation -<br />

and concrete pours were scheduled in<br />

the model. The model was used by the<br />

client for visualising the various phases<br />

of the project, and also by the<br />

workshop, which manufactured the<br />

steel structures, facilitating scheduling<br />

and fluent collaboration between the<br />

site and fabrication operations.<br />

Kopra stresses that visualising the<br />

structure in 3D with Tekla was a<br />

significant help in processing the<br />

information; for example for managing<br />

site operations. The bridge planning<br />

process was similarly streamlined, and,<br />

allowing the project team to avoid<br />

errors, resulted in time savings.<br />

"The planning process is simpler and<br />

clearer with BIM, and also more<br />

transparent for the different members of<br />

the project - for instance, BIM allowed<br />

the site crew to see and understand the<br />

bridge structure and the way it was to<br />

be erected. This makes planning work,<br />

as it allows the entire project to<br />

become more fluent, quicker and errorfree,"<br />

says Jarkko Savolainen, the<br />

project's building information specialist<br />

at A-Insinöörit Oy.<br />

The project parties chose Tekla Model<br />

Sharing to access the combined<br />

model. As a result, the model was<br />

always up to date and team members<br />

were able to access the accurate<br />

information they needed, when they<br />

needed it.<br />

FABRICATION, PROCUREMENT<br />

AND DELIVERY<br />

The project used BIM throughout its<br />

fabrication processes for manufacturing<br />

the different challenging steel<br />

structures, which were modelled<br />

originally as workshop models to test<br />

design and fabrication, and to sort out<br />

12<br />

November/December 2017