Equity Mag Jan_18 Book Folder

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

COLLECTOR'S PIECES<br />

watch brand was registered in London where Edouard’s<br />

brothers Alphonse and Frederic resided. Edouard<br />

continued to stay in Guangzhou to coordinate the imports<br />

while another brother, Gustave, was their watchmaker<br />

manufacturer based out of Fleurier.<br />

BOVET 2.0<br />

Bovet has two distinctive periods of existence. The first<br />

began in <strong>18</strong>22 and continued into the middle of the 20th<br />

century when the revolution in China took place in 1911<br />

forcing Bovet to downsize its China operations, followed<br />

by the two World Wars and a host of other factors meant<br />

that production ceased in 1960. It wasn’t until 2001 when<br />

Raffy who had already made a fortune from the<br />

pharmaceutical business and was an avid collector himself,<br />

decided to buy the brand and resurrect it.<br />

Raffy spent the next few years building the brand as a true<br />

manufacture that could rely on itself rather than third-party<br />

suppliers for the components it requires to make timepieces.<br />

This included buying the castle in Neuchatel where he set up<br />

an assembly and engraving workshop, as well as the Dimier<br />

1738 Manufacture de Haute Horlogerie Artisanale in<br />

Tramelan that specialised in movement creation and the<br />

Bovet <strong>18</strong>22 Manufacture de Cadrans et de Sertissage in Planles-Ouates<br />

which manufactures hand-crafted dials. The idea of<br />

becoming self-reliant early on is also what allowed Raffy to<br />

keep Bovet independent to this day. To further tap into the<br />

brand’s pedigreed roots, he even renamed it as Bovet <strong>18</strong>22.<br />

THE MANUFACTURE<br />

We visited the Dimier manufacture in Tramelan. It’s here<br />

where a Bovet watch begins life as nothing more than a<br />

few bits of metal in a workshop littered with industrial<br />

tools and machines. We see a “stamping” machine that<br />

presses down with a force of 30 tonnes to create the<br />

base of the movement. Lab coat-suited technicians nearby<br />

peer through Leica laser-guided magnifying machines to<br />

inspect the plate for imperfections.<br />

In a separate room, four people are engrossed in<br />

polishing and engraving the movement – for a complex<br />

engraving procedure, it can take nearly two days to finish<br />

the bridges of the movement alone.<br />

It’s in another room not far away where the most secretive<br />

and perhaps the most important function of Bovet’s watch<br />

manufacturing process takes place. It’s here where hairsprings<br />

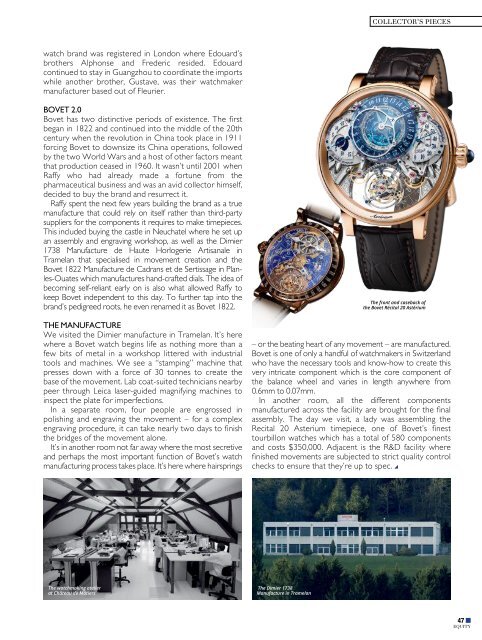

The front and caseback of<br />

the Bovet Récital 20 Astérium<br />

– or the beating heart of any movement – are manufactured.<br />

Bovet is one of only a handful of watchmakers in Switzerland<br />

who have the necessary tools and know-how to create this<br />

very intricate component which is the core component of<br />

the balance wheel and varies in length anywhere from<br />

0.6mm to 0.07mm.<br />

In another room, all the different components<br />

manufactured across the facility are brought for the final<br />

assembly. The day we visit, a lady was assembling the<br />

Recital 20 Asterium timepiece, one of Bovet’s finest<br />

tourbillon watches which has a total of 580 components<br />

and costs $350,000. Adjacent is the R&D facility where<br />

finished movements are subjected to strict quality control<br />

checks to ensure that they’re up to spec.<br />

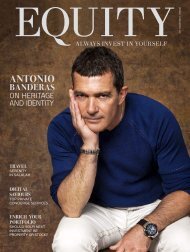

The watchmaking atelier<br />

at Château de Môtiers<br />

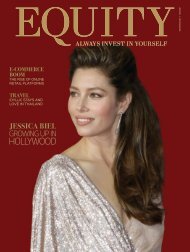

The Dimier 1738<br />

Manufacture in Tramelan<br />

47<br />

EQUITY