MU_2018_JanuaryFebruary-HR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

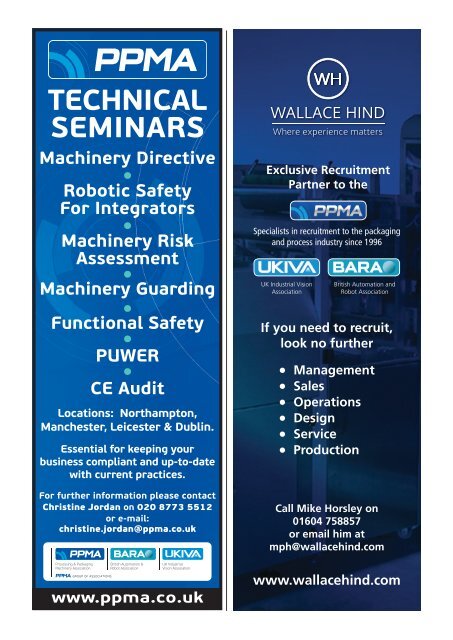

TECHNICAL<br />

SEMINARS<br />

Machinery Directive<br />

•<br />

Robotic Safety<br />

For Integrators<br />

•<br />

Machinery Risk<br />

Assessment<br />

•<br />

Machinery Guarding<br />

•<br />

Functional Safety<br />

•<br />

PUWER<br />

•<br />

CE Audit<br />

Locations: Northampton,<br />

Manchester, Leicester & Dublin.<br />

Essential for keeping your<br />

business compliant and up-to-date<br />

with current practices.<br />

For further information please contact<br />

Christine Jordan on 020 8773 5512<br />

or e-mail:<br />

christine.jordan@ppma.co.uk<br />

Exclusive Recruitment<br />

Partner to the<br />

Specialists in recruitment to the packaging<br />

and process industry since 1996<br />

UK Industrial Vision<br />

Association<br />

British Automation and<br />

Robot Association<br />

If you need to recruit,<br />

look no further<br />

• Management<br />

• Sales<br />

• Operations<br />

• Design<br />

• Service<br />

• Production<br />

Call Mike Horsley on<br />

01604 758857<br />

or email him at<br />

mph@wallacehind.com<br />

www.ppma.co.uk<br />

www.wallacehind.com