JTCS Volume 1 Issue 1

The Journal of Textile and Clothing Science (JTCS) is a peer-reviewed (refereed) journal. Which is aimed at providing the platform to exchange information pertaining to all sectors of textile and the clothing industry among researchers, textile technocrats, fashion designers and industry experts. The journal focuses on scientific, technical, economical, managerial and all other aspects of textile activity at theoretical and experimental level. JTCS is aimed at publishing original research articles, review papers, short communications, and letters to the editor and book reviews catering the needs of both industry and academia.

The Journal of Textile and Clothing Science (JTCS) is a peer-reviewed (refereed) journal. Which is aimed at providing the platform to exchange information pertaining to all sectors of textile and the clothing industry among researchers, textile technocrats, fashion designers and industry experts.

The journal focuses on scientific, technical, economical, managerial and all other aspects of textile activity at theoretical and experimental level. JTCS is aimed at publishing original research articles, review papers, short communications, and letters to the editor and book reviews catering the needs of both industry and academia.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Nonwoven orientation<br />

Extension (mm)<br />

Breaking load (N)<br />

Journal of Textile and Clothing Science<br />

property, for example, tensile strength and<br />

extension. The course of action of strands in<br />

nonwoven is depicted by the fiber pressing game<br />

plan as well as by fiber directional game plan that<br />

is fiber orientation. The web structure assumes a<br />

noteworthy part in deciding the physical normal<br />

for needle punched fabric. Needle punched fabric<br />

is centered around weight consistency that is MD<br />

and CD [8].<br />

The testing of nonwoven orientation is<br />

carried on lazing instrument NOS 200 machine by<br />

in house strategy. The impact of number of layers<br />

on fiber orientation is appeared if fig. 5.<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0.352<br />

Figure 5: Nonwoven orientation of fabric<br />

There is a huge impact of number of layers<br />

on fiber orientation. Fiber orientation increments<br />

as number of layers increments. There is 169.60%<br />

expansion in the orientation from number of layer<br />

6 to number of layer 10. There is a huge impact of<br />

number of layers on the nonwoven orientation of<br />

the fabric. As the quantity of layers builds the<br />

randomization of the of the strands increment<br />

which is spoken to by MD/CD ratio. The<br />

randomization is because of more number of<br />

filaments are laid in an alternate bearing for<br />

steady GSM of the fabric.<br />

3.6 Tensile Strength<br />

0.534<br />

0.949<br />

NL6 NL8 NL10<br />

Number of layers<br />

Mechanical properties of the material are<br />

critical where the material is subjected to stacking<br />

amid its execution. The tensile strength of needlepunched<br />

nonwoven is tried by ISO 9073-3<br />

standard on Instron 5967.<br />

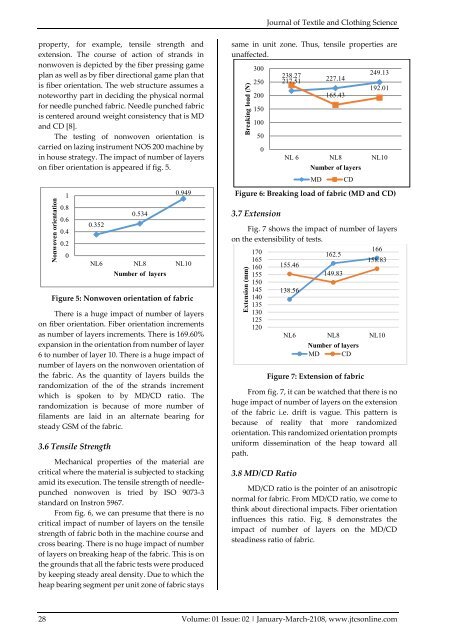

From fig. 6, we can presume that there is no<br />

critical impact of number of layers on the tensile<br />

strength of fabric both in the machine course and<br />

cross bearing. There is no huge impact of number<br />

of layers on breaking heap of the fabric. This is on<br />

the grounds that all the fabric tests were produced<br />

by keeping steady areal density. Due to which the<br />

heap bearing segment per unit zone of fabric stays<br />

same in unit zone. Thus, tensile properties are<br />

unaffected.<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Figure 6: Breaking load of fabric (MD and CD)<br />

3.7 Extension<br />

Fig. 7 shows the impact of number of layers<br />

on the extensibility of tests.<br />

170<br />

166<br />

162.5<br />

165<br />

158.83<br />

160 155.46<br />

155<br />

149.83<br />

150<br />

145 138.56<br />

140<br />

135<br />

130<br />

125<br />

120<br />

NL6 NL8 NL10<br />

Figure 7: Extension of fabric<br />

From fig. 7, it can be watched that there is no<br />

huge impact of number of layers on the extension<br />

of the fabric i.e. drift is vague. This pattern is<br />

because of reality that more randomized<br />

orientation. This randomized orientation prompts<br />

uniform dissemination of the heap toward all<br />

path.<br />

3.8 MD/CD Ratio<br />

238.27<br />

217.51 227.14<br />

165.43<br />

249.13<br />

192.01<br />

NL 6 NL8 NL10<br />

Number of layers<br />

MD<br />

CD<br />

Number of layers<br />

MD CD<br />

MD/CD ratio is the pointer of an anisotropic<br />

normal for fabric. From MD/CD ratio, we come to<br />

think about directional impacts. Fiber orientation<br />

influences this ratio. Fig. 8 demonstrates the<br />

impact of number of layers on the MD/CD<br />

steadiness ratio of fabric.<br />

28 <strong>Volume</strong>: 01 <strong>Issue</strong>: 02 | January-March-2108, www.jtcsonline.com