FLEISCHWIRTSCHAFT international 6/2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

............................................<br />

28<br />

Fleischwirtschaft <strong>international</strong> 6_<strong>2017</strong><br />

Coatings<br />

Apromising way to extend shelf life<br />

Source: KUMAR et al. <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 6_<strong>2017</strong><br />

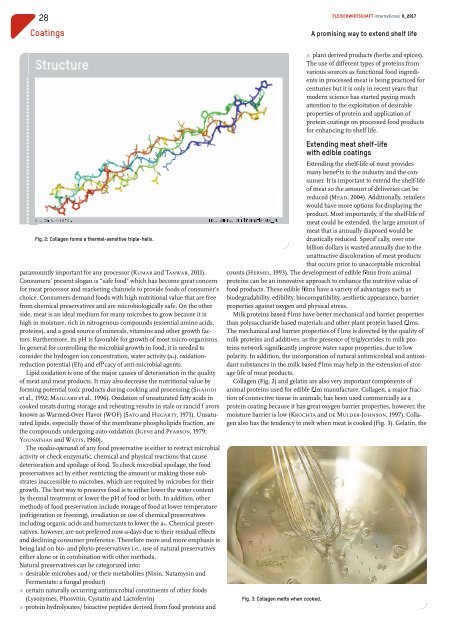

Fig. 2: Collagen forms athermal-sensitive triple-helix.<br />

paramountly important for any processor (KUMAR andTANWAR,2011).<br />

Consumers’ present slogan is “safe food”which has become great concern<br />

for meat processor and marketing channels to provide foods of consumer’s<br />

choice. Consumers demand foods with high nutritional value that are free<br />

from chemical preservatives and are microbiologically safe. On the other<br />

side, meat is an ideal medium for many microbes to grow because it is<br />

high in moisture, rich in nitrogenous compounds (essential amino acids,<br />

proteins), and agood source of minerals, vitamins and other growth factors.<br />

Furthermore, its pH is favorable for growth of most micro-organisms.<br />

In general for controlling the microbial growth in food, it is needed to<br />

consider the hydrogen ion concentration, water activity (aw), oxidationreduction<br />

potential (Eh) and effif cacy of anti-microbial agents.<br />

Lipid oxidation is one of the major causes of deterioration in the quality<br />

of meat and meat products. It may also decrease the nutritional value by<br />

forming potential toxic products during cooking and processing (SHAHIDI<br />

et al., 1992; MAILLARD et al., 1996). Oxidation of unsaturated fatty acids in<br />

cooked meats during storage and reheating results in stale or rancid fl<br />

avors<br />

known as Warmed-Over Flavor (WOF) (SATO and HEGARTY,1971).Unsaturated<br />

lipids, especially those of the membrane phospholipids fraction, are<br />

the compounds undergoing auto-oxidation (IGENE and PEARSON,1979;<br />

YOUNATHAN and WATTS,1960).<br />

The modus-operandi of any food preservative is either to restrict microbial<br />

activity or check enzymatic, chemical and physical reactions that cause<br />

deterioration and spoilage of food. To check microbial spoilage, the food<br />

preservatives act by either restricting the amount or making those substrates<br />

inaccessible to microbes, which are required by microbes for their<br />

growth. The best way to preserve food is to either lower the water content<br />

by thermal treatment or lower the pH of food or both. In addition, other<br />

methods of food preservation include storage of food at lower temperature<br />

(refrigeration or freezing), irradiation or use of chemical preservatives<br />

including organic acids and humectants to lower the aw.Chemical preservatives,<br />

however,are not preferred now-a-days due to their residual effects<br />

and declining consumer preference. Therefore more and more emphasis is<br />

being laid on bio- and phyto-preservatives i.e., use of natural preservatives<br />

either alone or in combination with other methods.<br />

Natural preservatives can be categorized into:<br />

r desirable microbes and/ or their metabolites (Nisin, Natamysin and<br />

Fermentate: afungal product)<br />

r certain naturally occurring antimicrobial constituents of other foods<br />

(Lysozymes, Phosvitin, Cystatin and Lactoferrin)<br />

r protein hydrolysates/ bioactive peptides derived from food proteins and<br />

r plant derived products (herbs and spices).<br />

The use of different types of proteins from<br />

various sources as functional food ingredients<br />

in processed meat is being practiced for<br />

centuries but it is only in recent years that<br />

modern science has started paying much<br />

attention to the exploitation of desirable<br />

properties of protein and application of<br />

protein coatings on processed food products<br />

for enhancing its shelf life.<br />

Extending meat shelf-life<br />

with edible coatings<br />

Extending the shelf-life of meat provides<br />

many benefi<br />

ts to the industry and the consumer.Itisimportant<br />

to extend the shelf-life<br />

of meat so the amount of deliveries can be<br />

reduced (MEAD,2004). Additionally,retailers<br />

would have more options for displaying the<br />

product. Most importantly,ifthe shelf-life of<br />

meat could be extended, the large amount of<br />

meat that is annually disposed would be<br />

drastically reduced. Specifi<br />

cally,over one<br />

billion dollars is wasted annually due to the<br />

unattractive discoloration of meat products<br />

that occurs prior to unacceptable microbial<br />

counts (HERMEL,1993). The development of edible fi<br />

lms from animal<br />

proteins can be an innovative approach to enhance the nutritive value of<br />

food products. These edible films have avariety of advantages such as<br />

biodegradability,edibility,biocompatibility,aesthetic appearance, barrier<br />

properties against oxygen and physical stress.<br />

Milk proteins based fi<br />

lms have better mechanical and barrier properties<br />

than polysaccharide based materials and other plant protein based films.<br />

The mechanical and barrier properties of fi<br />

lms is directed by the quality of<br />

milk proteins and additives, as the presence of triglycerides in milk proteins<br />

network signifi<br />

cantly improve water vapor properties, due to low<br />

polarity.Inaddition, the incorporation of natural antimicrobial and antioxidant<br />

substances in the milk based fi<br />

lms may help in the extension of storage<br />

life of meat products.<br />

Collagen (Fig. 2) and gelatin are also very important components of<br />

animal proteins used for edible fi<br />

lm manufacture. Collagen, amajor fraction<br />

of connective tissue in animals, has been used commercially as a<br />

protein coating because it has great oxygen barrier properties, however,the<br />

moisture barrier is low (KROCHTA and DE MULDER-JOHNSON,1997). Collagen<br />

also has the tendency to melt when meat is cooked (Fig. 3). Gelatin, the<br />

Fig. 3: Collagen melts when cooked.