A C 2 x screw à  B - BiERBACH GmbH & Co. KG Befestigungstechnik

A C 2 x screw à  B - BiERBACH GmbH & Co. KG Befestigungstechnik

A C 2 x screw à  B - BiERBACH GmbH & Co. KG Befestigungstechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

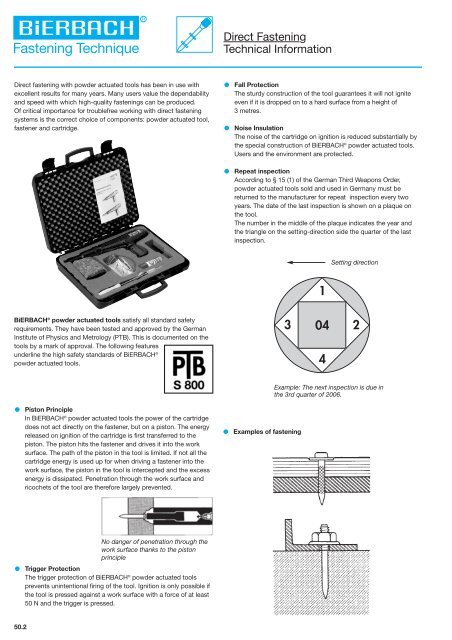

Fastening Technique<br />

Direct fastening with powder actuated tools has been in use with<br />

excellent results for many years. Many users value the dependability<br />

and speed with which high-quality fastenings can be produced.<br />

Of critical importance for troublefree working with direct fastening<br />

systems is the correct choice of components: powder actuated tool,<br />

fastener and cartridge.<br />

<strong>BiERBACH</strong> ® powder actuated tools satisfy all standard safety<br />

requirements. They have been tested and approved by the German<br />

Institute of Physics and Metrology (PTB). This is documented on the<br />

tools by a mark of approval. The following features<br />

underline the high safety standards of <strong>BiERBACH</strong> ®<br />

powder actuated tools.<br />

● Piston Principle<br />

In <strong>BiERBACH</strong> ® powder actuated tools the power of the cartridge<br />

does not act directly on the fastener, but on a piston. The energy<br />

released on ignition of the cartridge is first transferred to the<br />

piston. The piston hits the fastener and drives it into the work<br />

surface. The path of the piston in the tool is limited. If not all the<br />

cartridge energy is used up for when driving a fastener into the<br />

work surface, the piston in the tool is intercepted and the excess<br />

energy is dissipated. Penetration through the work surface and<br />

ricochets of the tool are therefore largely prevented.<br />

● Trigger Protection<br />

The trigger protection of <strong>BiERBACH</strong> ® powder actuated tools<br />

prevents unintentional firing of the tool. Ignition is only possible if<br />

the tool is pressed against a work surface with a force of at least<br />

50 N and the trigger is pressed.<br />

50.2<br />

R<br />

No danger of penetration through the<br />

work surface thanks to the piston<br />

principle<br />

Direct Fastening<br />

Technical Information<br />

● Fall Protection<br />

The sturdy construction of the tool guarantees it will not ignite<br />

even if it is dropped on to a hard surface from a height of<br />

3 metres.<br />

● Noise Insulation<br />

The noise of the cartridge on ignition is reduced substantially by<br />

the special construction of <strong>BiERBACH</strong> ® powder actuated tools.<br />

Users and the environment are protected.<br />

● Repeat inspection<br />

According to § 15 (1) of the German Third Weapons Order,<br />

powder actuated tools sold and used in Germany must be<br />

returned to the manufacturer for repeat inspection every two<br />

years. The date of the last inspection is shown on a plaque on<br />

the tool.<br />

The number in the middle of the plaque indicates the year and<br />

the triangle on the setting-direction side the quarter of the last<br />

inspection.<br />

3<br />

● Examples of fastening<br />

1<br />

04<br />

4<br />

Setting direction<br />

2<br />

Example: The next inspection is due in<br />

the 3rd quarter of 2006.