Book of abstracts version 5

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Book</strong> <strong>of</strong> <strong>abstracts</strong> SPOC 2018<br />

Biobased Polyesters From Ferulic Acid Derivatives<br />

Author<br />

Robin van den Kieboom<br />

Academy <strong>of</strong> Technology for Health and Environment<br />

Avans Hogeschool, Breda<br />

Dennis Molendijk, Jack van Schijndel<br />

esters From Ferulic Acid Derivatives<br />

Abstract<br />

The polymer industry is one <strong>of</strong> the most important chemical industries in the world. Many <strong>of</strong> the polymers used<br />

worldwide are based from oil. 4% <strong>of</strong> the global oil- and gas production is used to produce polymers [1]. With the oil<br />

reserves slowly running dry, the demand for biobased polymers is quickly rising. Polyesters synthesized from ferulic acid<br />

could be a possible replacement for the oil-based PET (polyethylene terephthalate). Ferulic acid is a hydroxycinnamic acid<br />

derivative that can be produced from vanillin, a naturally occurring hydroxybenzaldehyde. The aim <strong>of</strong> this project produce<br />

at least dimers from ferulic acid, using a melt-polycondensation reaction. Secondly, to hydrolyse the polymer back to<br />

monomer, and finally, to re-polymerize the monomer to prove that the polymer can be recycled. FTIR, HPLC, DSC and<br />

HNMR were used to analyse both the polymer and monomer. A yield <strong>of</strong> at leas t 70% was expected within 3 hours. The<br />

project started with a screening (1/5 <strong>of</strong> full-scale) to find de fastest catalyst for the polycondensation. The catalysts were<br />

chosen for their use in standard esterfications, and cons isted <strong>of</strong> various Lewis acids [2] and Bronsted acids. This catalyst<br />

was used in the full-scale polymerisation. 5 mol% catalyst was used in both cases. The polycondensation was executed<br />

under vacuum at 110ºC. The reaction stops when the melting point <strong>of</strong> the polymer exceeds this temperature. After<br />

analysis the polymer was hydrolysed using 1M NaOH solution, and purified with L/L extraction to retrieve the monomer.<br />

Keywords: Polyester, Ferulic Acid, Biobased Polymer, PET replacement, Polymerisation, Polycondensation, Melt -<br />

Polycondensation, Hydrolysis.<br />

Table <strong>of</strong> contents<br />

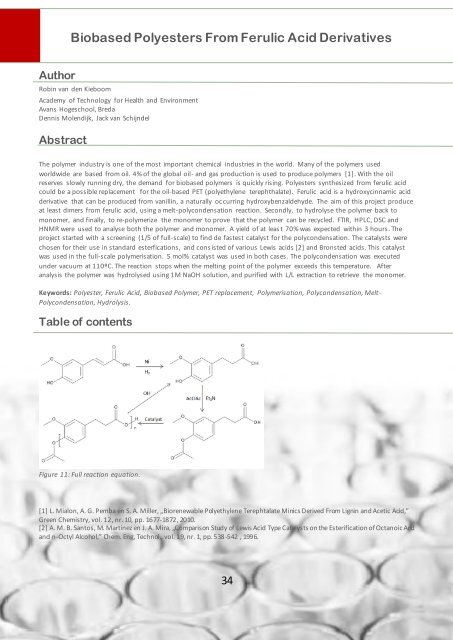

Figure 11: Full reaction equation.<br />

[1] L. Mialon, A. G. Pemba en S. A. Miller, „Biorenewable Polyethylene Terephtalate Minics Derived From Lignin and Acetic Acid,”<br />

Green Chemistry, vol. 12, nr. 10, pp. 1677-1872, 2010.<br />

[2] A. M. B. Santos, M. Martinez en J. A. Mira, „Comparison Study <strong>of</strong> Lewis Acid Type Catalysts on the Esterification <strong>of</strong> Octanoic Acid<br />

and n-Octyl Alcohol,” Chem. Eng, Technol., vol. 19, nr. 1, pp. 538 -542 , 1996.<br />

34