Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

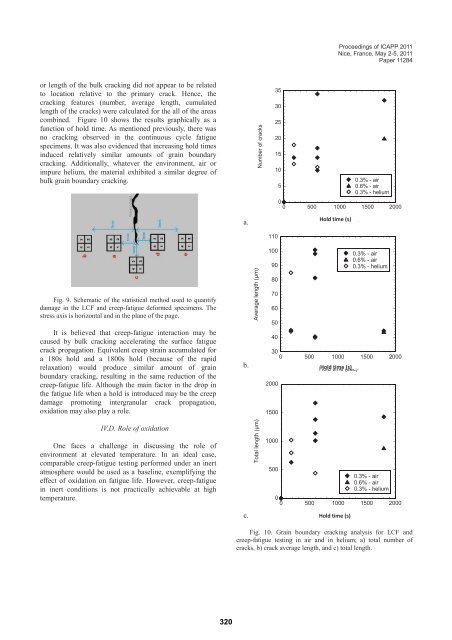

or length <strong>of</strong> the bulk cracking did not appear to be related<br />

to location relative to the primary crack. Hence, the<br />

cracking features (number, average length, cumulated<br />

length <strong>of</strong> the cracks) were calculated <strong>for</strong> the all <strong>of</strong> the areas<br />

combined. Figure 10 shows the results graphically as a<br />

function <strong>of</strong> hold time. As mentioned previously, there was<br />

no cracking observed in the continuous cycle <strong>fatigue</strong><br />

specimens. It was also evidenced that increasing hold times<br />

induced relatively similar amounts <strong>of</strong> grain boundary<br />

cracking. Additionally, whatever the environment, air or<br />

impure helium, the material exhibited a similar degree <strong>of</strong><br />

bulk grain boundary cracking.<br />

Fig. 9. Schematic <strong>of</strong> the statistical method used to quantify<br />

damage in the LCF and creep-<strong>fatigue</strong> de<strong>for</strong>med specimens. The<br />

stress axis is horizontal and in the plane <strong>of</strong> the page.<br />

It is believed that creep-<strong>fatigue</strong> interaction may be<br />

caused by bulk cracking accelerating the surface <strong>fatigue</strong><br />

crack propagation. Equivalent creep strain accumulated <strong>for</strong><br />

a 180s hold and a 1800s hold (because <strong>of</strong> the rapid<br />

relaxation) would produce similar amount <strong>of</strong> grain<br />

boundary cracking, resulting in the same reduction <strong>of</strong> the<br />

creep-<strong>fatigue</strong> life. Although the main factor in the drop in<br />

the <strong>fatigue</strong> life when a hold is introduced may be the creep<br />

damage promoting intergranular crack propagation,<br />

oxidation may also play a role.<br />

IV.D. Role <strong>of</strong> oxidation<br />

One faces a challenge in discussing the role <strong>of</strong><br />

environment at elevated temperature. In an ideal case,<br />

comparable creep-<strong>fatigue</strong> testing per<strong>for</strong>med under an inert<br />

atmosphere would be used as a baseline, exemplifying the<br />

effect <strong>of</strong> oxidation on <strong>fatigue</strong> life. However, creep-<strong>fatigue</strong><br />

in inert conditions is not practically achievable at high<br />

temperature.<br />

320<br />

a.<br />

b.<br />

c.<br />

Number <strong>of</strong> cracks<br />

Average length (μm)<br />

Total length (μm)<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Proceedings <strong>of</strong> ICAPP 2011<br />

Nice, France, May 2-5, 2011<br />

Paper 11284<br />

0.3% - air<br />

0.6% - air<br />

0.3% - helium<br />

0<br />

0 500 1000 1500 2000<br />

��������������<br />

Hold Time (sec)<br />

0.3% - air<br />

0.6% - air<br />

0.3% - helium<br />

30<br />

0 500 1000<br />

Hold �������������� time (sec)<br />

1500 2000<br />

2000<br />

1500<br />

1000<br />

500<br />

0.3% - air<br />

0.6% - air<br />

0.3% - helium<br />

0<br />

0 500 1000 1500 2000<br />

��������������<br />

Hold time (sec)<br />

Fig. 10. Grain boundary cracking analysis <strong>for</strong> LCF and<br />

creep-<strong>fatigue</strong> testing in air and in helium; a) total number <strong>of</strong><br />

cracks, b) crack average length, and c) total length.