Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

- An area free <strong>of</strong> grain boundary carbides has evolved<br />

in the subsurface. Such a carbide-depletion was also<br />

evidenced in the region surrounding the primary<br />

creep-<strong>fatigue</strong> cracks. Carbide dissolution was<br />

related to the diffusion <strong>of</strong> chromium to the surface<br />

(<strong>of</strong> the specimen or <strong>of</strong> the crack) to <strong>for</strong>m the<br />

chromia scale. Chromium removal then may have<br />

destabilized the grain boundary Cr-rich carbides in<br />

the subsurface area.<br />

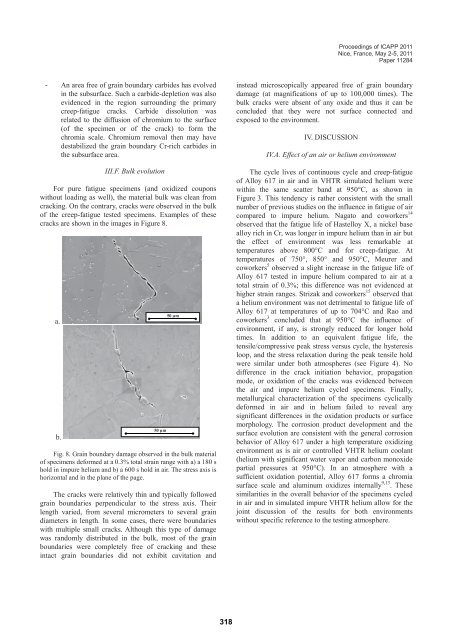

III.F. Bulk evolution<br />

For pure <strong>fatigue</strong> specimens (and oxidized coupons<br />

without loading as well), the material bulk was clean from<br />

cracking. On the contrary, cracks were observed in the bulk<br />

<strong>of</strong> the creep-<strong>fatigue</strong> tested specimens. Examples <strong>of</strong> these<br />

cracks are shown in the images in Figure 8.<br />

a.<br />

b.<br />

50 µm<br />

50 µm<br />

Fig. 8. Grain boundary damage observed in the bulk material<br />

<strong>of</strong> specimens de<strong>for</strong>med at a 0.3% total strain range with a) a 180 s<br />

hold in impure helium and b) a 600 s hold in air. The stress axis is<br />

horizontal and in the plane <strong>of</strong> the page.<br />

The cracks were relatively thin and typically followed<br />

grain boundaries perpendicular to the stress axis. Their<br />

length varied, from several micrometers to several grain<br />

diameters in length. In some cases, there were boundaries<br />

with multiple small cracks. Although this type <strong>of</strong> damage<br />

was randomly distributed in the bulk, most <strong>of</strong> the grain<br />

boundaries were completely free <strong>of</strong> cracking and these<br />

intact grain boundaries did not exhibit cavitation and<br />

318<br />

Proceedings <strong>of</strong> ICAPP 2011<br />

Nice, France, May 2-5, 2011<br />

Paper 11284<br />

instead microscopically appeared free <strong>of</strong> grain boundary<br />

damage (at magnifications <strong>of</strong> up to 100,000 times). The<br />

bulk cracks were absent <strong>of</strong> any oxide and thus it can be<br />

concluded that they were not surface connected and<br />

exposed to the environment.<br />

IV. DISCUSSION<br />

IV.A. <strong>Effect</strong> <strong>of</strong> an air or helium environment<br />

The cycle lives <strong>of</strong> continuous cycle and creep-<strong>fatigue</strong><br />

<strong>of</strong> Alloy 617 in air and in <strong>VHTR</strong> simulated helium were<br />

within the same scatter band at 950°C, as shown in<br />

Figure 3. This tendency is rather consistent with the small<br />

number <strong>of</strong> previous studies on the influence in <strong>fatigue</strong> <strong>of</strong> air<br />

compared to impure helium. Nagato and coworkers 14<br />

observed that the <strong>fatigue</strong> life <strong>of</strong> Hastelloy X, a nickel base<br />

alloy rich in Cr, was longer in impure helium than in air but<br />

the effect <strong>of</strong> environment was less remarkable at<br />

temperatures above 800°C and <strong>for</strong> creep-<strong>fatigue</strong>. At<br />

temperatures <strong>of</strong> 750°, 850° and 950°C, Meurer and<br />

coworkers 5 observed a slight increase in the <strong>fatigue</strong> life <strong>of</strong><br />

Alloy 617 tested in impure helium compared to air at a<br />

total strain <strong>of</strong> 0.3%; this difference was not evidenced at<br />

higher strain ranges. Strizak and coworkers 15 observed that<br />

a helium environment was not detrimental to <strong>fatigue</strong> life <strong>of</strong><br />

Alloy 617 at temperatures <strong>of</strong> up to 704°C and Rao and<br />

coworkers 3 concluded that at 950°C the influence <strong>of</strong><br />

environment, if any, is strongly reduced <strong>for</strong> longer hold<br />

times. In addition to an equivalent <strong>fatigue</strong> life, the<br />

tensile/compressive peak stress versus cycle, the hysteresis<br />

loop, and the stress relaxation during the peak tensile hold<br />

were similar under both atmospheres (see Figure 4). No<br />

difference in the crack initiation behavior, propagation<br />

mode, or oxidation <strong>of</strong> the cracks was evidenced between<br />

the air and impure helium cycled specimens. Finally,<br />

metallurgical characterization <strong>of</strong> the specimens cyclically<br />

de<strong>for</strong>med in air and in helium failed to reveal any<br />

significant differences in the oxidation products or surface<br />

morphology. The corrosion product development and the<br />

surface evolution are consistent with the general corrosion<br />

behavior <strong>of</strong> Alloy 617 under a high temperature oxidizing<br />

environment as is air or controlled <strong>VHTR</strong> helium coolant<br />

(helium with significant water vapor and carbon monoxide<br />

partial pressures at 950°C). In an atmosphere with a<br />

sufficient oxidation potential, Alloy 617 <strong>for</strong>ms a chromia<br />

surface scale and aluminum oxidizes internally 9,13 . These<br />

similarities in the overall behavior <strong>of</strong> the specimens cycled<br />

in air and in simulated impure <strong>VHTR</strong> helium allow <strong>for</strong> the<br />

joint discussion <strong>of</strong> the results <strong>for</strong> both environments<br />

without specific reference to the testing atmosphere.