Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Creep-fatigue of High Temperature Materials for VHTR: Effect of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

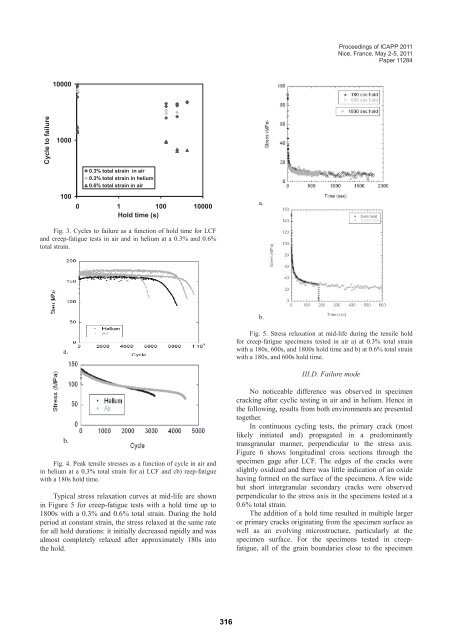

Cycle to failure<br />

10000<br />

1000<br />

100<br />

0.3% total strain in air<br />

0.3% total strain in helium<br />

0.6% total strain in air<br />

0,01 1 100 10000<br />

Hold time (s)<br />

Fig. 3. Cycles to failure as a function <strong>of</strong> hold time <strong>for</strong> LCF<br />

and creep-<strong>fatigue</strong> tests in air and in helium at a 0.3% and 0.6%<br />

total strain.<br />

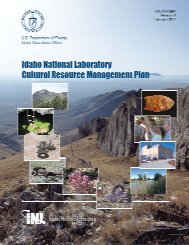

a.<br />

b.<br />

Fig. 4. Peak tensile stresses as a function <strong>of</strong> cycle in air and<br />

in helium at a 0.3% total strain <strong>for</strong> a) LCF and cb) reep-<strong>fatigue</strong><br />

with a 180s hold time.<br />

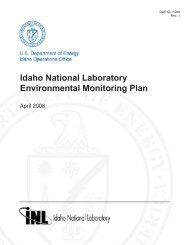

Typical stress relaxation curves at mid-life are shown<br />

in Figure 5 <strong>for</strong> creep-<strong>fatigue</strong> tests with a hold time up to<br />

1800s with a 0.3% and 0.6% total strain. During the hold<br />

period at constant strain, the stress relaxed at the same rate<br />

<strong>for</strong> all hold durations: it initially decreased rapidly and was<br />

almost completely relaxed after approximately 180s into<br />

the hold.<br />

316<br />

a.<br />

b.<br />

Proceedings <strong>of</strong> ICAPP 2011<br />

Nice, France, May 2-5, 2011<br />

Paper 11284<br />

Fig. 5. Stress relaxation at mid-life during the tensile hold<br />

<strong>for</strong> creep-<strong>fatigue</strong> specimens tested in air a) at 0.3% total strain<br />

with a 180s, 600s, and 1800s hold time and b) at 0.6% total strain<br />

with a 180s, and 600s hold time.<br />

III.D. Failure mode<br />

No noticeable difference was observed in specimen<br />

cracking after cyclic testing in air and in helium. Hence in<br />

the following, results from both environments are presented<br />

together.<br />

In continuous cycling tests, the primary crack (most<br />

likely initiated and) propagated in a predominantly<br />

transgranular manner, perpendicular to the stress axis.<br />

Figure 6 shows longitudinal cross sections through the<br />

specimen gage after LCF. The edges <strong>of</strong> the cracks were<br />

slightly oxidized and there was little indication <strong>of</strong> an oxide<br />

having <strong>for</strong>med on the surface <strong>of</strong> the specimens. A few wide<br />

but short intergranular secondary cracks were observed<br />

perpendicular to the stress axis in the specimens tested at a<br />

0.6% total strain.<br />

The addition <strong>of</strong> a hold time resulted in multiple larger<br />

or primary cracks originating from the specimen surface as<br />

well as an evolving microstructure, particularly at the<br />

specimen surface. For the specimens tested in creep<strong>fatigue</strong>,<br />

all <strong>of</strong> the grain boundaries close to the specimen