You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COST<br />

MED Cambelt conversion - £350<br />

Spare seal kit - £10<br />

Replacement timing belt - £45<br />

CONTACT<br />

www.med-engineering.co.uk<br />

01455 618464<br />

DIFFICULTY<br />

Words and Photography Stephen Colbran<br />

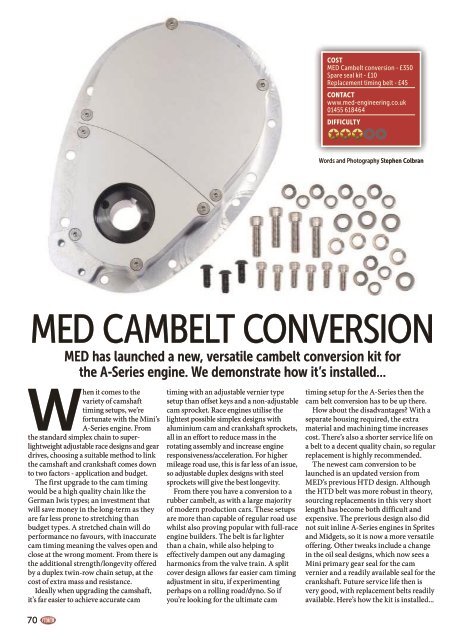

MED CAMBELT CONVERSION<br />

MED has launched a new, versatile cambelt conversion kit for<br />

the A-Series engine. We demonstrate how it’s installed...<br />

When it comes to the<br />

variety of camshaft<br />

timing setups, we’re<br />

fortunate with the <strong>Mini</strong>’s<br />

A-Series engine. From<br />

the standard simplex chain to superlightweight<br />

adjustable race designs and gear<br />

drives, choosing a suitable method to link<br />

the camshaft and crankshaft comes down<br />

to two factors - application and budget.<br />

The first upgrade to the cam timing<br />

would be a high quality chain like the<br />

German Iwis types; an investment that<br />

will save money in the long-term as they<br />

are far less prone to stretching than<br />

budget types. A stretched chain will do<br />

performance no favours, with inaccurate<br />

cam timing meaning the valves open and<br />

close at the wrong moment. From there is<br />

the additional strength/longevity offered<br />

by a duplex twin-row chain setup, at the<br />

cost of extra mass and resistance.<br />

Ideally when upgrading the camshaft,<br />

it’s far easier to achieve accurate cam<br />

70<br />

timing with an adjustable vernier type<br />

setup than offset keys and a non-adjustable<br />

cam sprocket. Race engines utilise the<br />

lightest possible simplex designs with<br />

aluminium cam and crankshaft sprockets,<br />

all in an effort to reduce mass in the<br />

rotating assembly and increase engine<br />

responsiveness/acceleration. For higher<br />

mileage road use, this is far less of an issue,<br />

so adjustable duplex designs with steel<br />

sprockets will give the best longevity.<br />

From there you have a conversion to a<br />

rubber cambelt, as with a large majority<br />

of modern production cars. These setups<br />

are more than capable of regular road use<br />

whilst also proving popular with full-race<br />

engine builders. The belt is far lighter<br />

than a chain, while also helping to<br />

effectively dampen out any damaging<br />

harmonics from the valve train. A split<br />

cover design allows far easier cam timing<br />

adjustment in situ, if experimenting<br />

perhaps on a rolling road/dyno. So if<br />

you’re looking for the ultimate cam<br />

timing setup for the A-Series then the<br />

cam belt conversion has to be up there.<br />

How about the disadvantages? With a<br />

separate housing required, the extra<br />

material and machining time increases<br />

cost. There’s also a shorter service life on<br />

a belt to a decent quality chain, so regular<br />

replacement is highly recommended.<br />

The newest cam conversion to be<br />

launched is an updated version from<br />

MED’s previous HTD design. Although<br />

the HTD belt was more robust in theory,<br />

sourcing replacements in this very short<br />

length has become both difficult and<br />

expensive. The previous design also did<br />

not suit inline A-Series engines in Sprites<br />

and Midgets, so it is now a more versatile<br />

offering. Other tweaks include a change<br />

in the oil seal designs, which now sees a<br />

<strong>Mini</strong> primary gear seal for the cam<br />

vernier and a readily available seal for the<br />

crankshaft. Future service life then is<br />

very good, with replacement belts readily<br />

available. Here’s how the kit is installed...