BRO Steam Solutions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

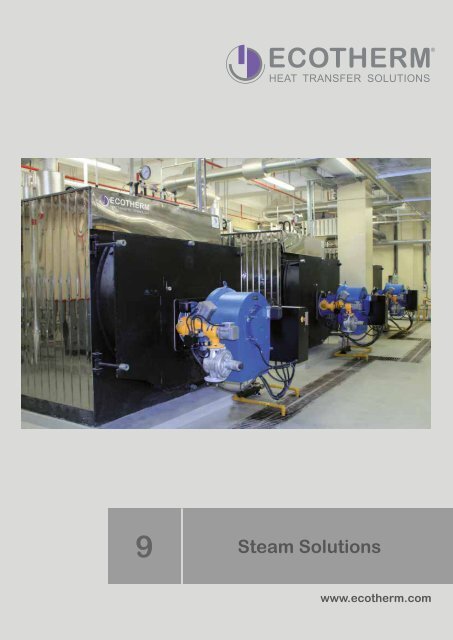

9<br />

<strong>Steam</strong> <strong>Solutions</strong><br />

www.ecotherm.com

Company profile<br />

ECOTHERM is the leading brand for turnkey hot water,<br />

steam and solar systems for hotels, hospitals and<br />

industry in the Middle East.<br />

ECOTHERM amazes its customers with “Individual Heat<br />

Transfer <strong>Solutions</strong>” for hot water, steam and solar generation.<br />

The following advantages mark these solutions:<br />

Individuality<br />

ECOTHERM realizes extensive turnkey systems as well<br />

as the production of separate components. Each single<br />

plant is specifically aligned to the customer’s individual<br />

requirements. The basis is an own production in Austria<br />

and a wide product portfolio.<br />

Premium quality<br />

All products made of high-class duplex stainless<br />

steel guarantee a long-life cycle and perfect hygiene.<br />

ECOTHERM is certified to ISO 9001 : 2008 with all<br />

required European standards.<br />

Innovation<br />

We are always open to the new, we constantly investigate<br />

new technologies and we develop path-breaking and future-oriented<br />

products.<br />

Premium service<br />

Clients benefit from extensive service at consulting, planning,<br />

engineering, supervision and training. ECOTHERM<br />

regularly improves the know-how of its partners and clients<br />

via selective trainings.<br />

Efficiency<br />

The ECOTHERM Group managed by the owner has slim<br />

decision-making structures. ECOTHERM turnkey solutions<br />

from one single source and the economical handling<br />

of energy resources offer an optimal cost-benefit ratio.<br />

Experience<br />

With thousands of installations the past 30 years in<br />

Europe, the Middle East, Asia, North Africa and Central<br />

America, ECOTHERM has become one of the technology<br />

and innovation leaders for individual hot water, steam and<br />

solar solutions on the market.<br />

Reliability<br />

ECOTHERM systems are monitored around the clock<br />

and can be serviced at low cost, quickly and efficiently via<br />

an advance control panel. Our designed plants have low<br />

maintenance requirements and are<br />

totally dependable.<br />

Sustainability<br />

ECOTHERM products help our customers to save energy<br />

and money. We save valuable resources through the use<br />

of renewable energies. ECOTHERM high-performance<br />

plants have minimal space requirements and provide<br />

maximum energy savings. When planning new products<br />

ECOTHERM engineers take all the qualitative and economic<br />

principles into account in accordance with ecological<br />

principles.<br />

Partnership<br />

We live in a partnership with all our customers, suppliers<br />

and employees. This relationship is characterized by<br />

honesty, commitment, openness, trust and reliability.<br />

The object is a joint long-term success.<br />

Internationality<br />

The international alignment of ECOTHERM with branches<br />

in Dubai, Kuwait, Mexico, Hungary, India and partners in<br />

more than 20 countries is the basis for our flexible and<br />

efficient project implementation that is always on schedule.<br />

2 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Water Sample<br />

Cooler<br />

<strong>Steam</strong> Seperator<br />

Fuel Burner<br />

Blow Down<br />

Cooler<br />

Flash<br />

Vessel<br />

<strong>Steam</strong> Flow<br />

Meter<br />

Heat<br />

Recovery<br />

Stainless Steel<br />

Chimney<br />

Plant<br />

<strong>Steam</strong> Boiler<br />

Economizer<br />

Heat<br />

Recovery<br />

<strong>Steam</strong> Header<br />

Feed<br />

Water<br />

Pumps<br />

Deaerator<br />

Feed Water<br />

Tank<br />

Pressure Reducing Station<br />

Master Control Panel<br />

Fresh Water<br />

Supply<br />

Water Softener & Chemical Dosing<br />

Condensate Recovery<br />

Reverse Osmose<br />

Clean <strong>Steam</strong><br />

Generator<br />

Legend<br />

<strong>Steam</strong> supply<br />

Condensate return<br />

Blow down<br />

Cold water<br />

Hot water<br />

Waste water<br />

Vent<br />

Contents<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

Your optimal solution Pages 6 - 7<br />

Products:<br />

• <strong>Steam</strong> Boilers<br />

• Economizers<br />

• Chimneys<br />

• Burners<br />

• Feed Water Tanks<br />

• Blown Down Coolers & Flash Vessels<br />

• Water Treatment<br />

• Control Panels<br />

• Condensate Return Station<br />

• Pressure Reducing Stations<br />

• Automatic Blown Down Systems<br />

• Automatic TDS Control Units<br />

• Level Control for <strong>Steam</strong> Boilers<br />

• Valves, instruments & steam ancillaries<br />

• <strong>Steam</strong> Flow Metering<br />

• Feed Water Pumps<br />

• <strong>Steam</strong> Headers<br />

• <strong>Steam</strong> Separators<br />

• Sample Coolers<br />

Pages 7 - 8<br />

Page 9<br />

Page 10<br />

Page 11<br />

Pages 12 - 13<br />

Page 14<br />

Pages 15-16<br />

Page 17<br />

Page 18<br />

Page 18<br />

Page 19<br />

Page 19<br />

Page 19<br />

Page 20<br />

Page 20<br />

Page 20<br />

Page 21<br />

Page 21<br />

Page 21<br />

Turnkey <strong>Solutions</strong>:<br />

• (Pre-)Wiring<br />

• (Pre-)Piping<br />

• Pipe Supports<br />

• Vapour Heat Exchangers<br />

• ECOTHERM High Capacity Water Heaters<br />

• High Capacity Clean <strong>Steam</strong> Generators<br />

• Smart <strong>Steam</strong> Generators<br />

Page 23<br />

Page 23<br />

Page 23<br />

Page 24<br />

Page 24<br />

Pages 25 - 26<br />

Pages 27 - 28<br />

Advantages<br />

Pages 29 - 33<br />

Technical Specifications<br />

Pages 34 - 54<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

3

Your optimal solution<br />

Your optimal ECOTHERM steam solution<br />

For steam systems much more components<br />

are required than for hot water<br />

systems. The spectrum ranges<br />

from oil or gas burners over feed<br />

water tanks, water treatment, clean<br />

steam generators, condensate recovery<br />

systems, steam separators up to<br />

the control panel with a touch panel.<br />

There fore ECOTHERM already plans<br />

80 to 90 percent of all details for a system<br />

in the design stage. This ensures<br />

that the suggested time schedule really<br />

works, that the costs for the project<br />

suit the suggested budget and that the<br />

desired performance can be achieved<br />

by the system. ECOTHERM steam<br />

systems are mainly installed in hotels<br />

(e. g. for the laundry), in hospitals<br />

(especially clean steam generators<br />

for e. g. cleaning the surgical instruments)<br />

or in industry.<br />

Chimneys<br />

High quality stainless steel chimneys<br />

for industrial applications and<br />

individual residental buildings.<br />

Details on page 10.<br />

Flash<br />

Vessel<br />

<strong>Steam</strong> Header<br />

Heat<br />

Recovery<br />

<strong>Steam</strong> Boilers<br />

Blow Down<br />

Cooler<br />

High efficiency, fully packaged for<br />

easy installation, robust long life.<br />

Details on pages 7 to 8.<br />

<strong>Steam</strong> Flow<br />

Meter<br />

Stainless Steel<br />

Chimney<br />

Water Sample<br />

Cooler<br />

Economizer<br />

Deaerator<br />

Smart <strong>Steam</strong> Generators<br />

Feed Water<br />

Tank<br />

High energy efficiency, robust and lowmaintenance<br />

and easy operation.<br />

Details on pages 27 to 28.<br />

<strong>Steam</strong> Seperator<br />

Heat<br />

Recovery<br />

Burners<br />

Fuel Burner<br />

Plant<br />

<strong>Steam</strong> Boiler<br />

Feed<br />

Water<br />

Pumps<br />

Gas, oil or dual fuel burners with highefficiency<br />

and approved quality.<br />

Details on page 11.<br />

Economizers<br />

Feed Water Tanks<br />

Significantly increases the boiler<br />

efficiency up to 97 percent.<br />

Details on page 9.<br />

High quality workmanship to highest<br />

European standards.<br />

Details on pages 12 to 13.<br />

4 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Your optimal solution<br />

Control Panels<br />

Touchscreen, 3D visualization, remote<br />

access.<br />

Details on page 17.<br />

Condensate<br />

Return Stations<br />

Fully packaged unit, ready for start-up<br />

Details on page 18.<br />

Turnkey <strong>Solutions</strong><br />

ECOTHERM offers complete turnkey<br />

steam solutions with a huge range of<br />

additional components as e. g.<br />

• (Pre-)Piping<br />

• Pipe supports<br />

• (Pre-)Wiring<br />

• Vapour heat exchangers<br />

• ECOTHERM high capacity water<br />

heaters<br />

• High capacity clean steam<br />

generators<br />

• Smart <strong>Steam</strong> Generators<br />

Pressure Reducing Station<br />

Clean <strong>Steam</strong><br />

Generator<br />

Details on pages 22 to 28.<br />

This schematic drawing<br />

shows the components of<br />

a typical ECOTHERM<br />

steam system.<br />

Master Control Panel<br />

Legend<br />

<strong>Steam</strong> supply<br />

Condensate return<br />

Blow down<br />

Cold water<br />

Hot water<br />

Waste water<br />

Vent<br />

Condensate Recovery<br />

Fresh Water<br />

Supply<br />

Water Softener & Chemical Dosing<br />

Clean <strong>Steam</strong> Generators<br />

Entirely made of high quality stainless<br />

steel. Compact, skid mounted unit.<br />

Details on pages 25 to 26.<br />

Reverse Osmose<br />

Blown Down Coolers<br />

Guarantee a safe waste water<br />

management. Details on page 14.<br />

Water Treatment<br />

In order to prevent the steam system<br />

against corrosion and scale foundation,<br />

certain components for the water treatment<br />

are added to the system as e. g.:<br />

• Water softener<br />

• Chemical dosing<br />

• Water filter<br />

• Hardness control<br />

• Reverse osmose systems<br />

Details on pages 15 to 16.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

5

Products<br />

ECOTHERM steam systems consist of high quality<br />

components. Clean steam generators are made of<br />

high quality stainless steel. This high capacity products<br />

are manufactured at the ECOTHERM headquarters<br />

in Austria. The quality management system<br />

of ECOTHERM is certified according to ISO 9001 :<br />

2008 for sizing, design, production and distribution<br />

of solar, hot water and steam systems as well as of<br />

pressure vessels and heat exchangers.<br />

The products are manufactured in high quality<br />

stainless steel according to the highest European<br />

standards as e. g. ISO 3834-2 and therefore guarantee<br />

long life time and perfect hygiene. Our own<br />

test bench assures the highest quality and reliability.<br />

6 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: <strong>Steam</strong> boilers<br />

ESBI <strong>Steam</strong> Boilers<br />

Low Capacities<br />

350 - 5,000 kg/h<br />

Technical details on page 36<br />

High Capacities<br />

1,700 - 20,000 kg/h<br />

Technical details on page 37<br />

Efficiency & admissible<br />

maximum safety valve<br />

pressure<br />

• Efficiency of up to 91% and<br />

up to 95% with economizer<br />

can be achieved.<br />

• Standard design pressures<br />

of 10,13,16 and 20 bar(g)<br />

are available.<br />

Higher pressures can be manufactured<br />

on request.<br />

Design, quality & construction<br />

The ECOTHERM high output steam<br />

boilers are constructed from high quality<br />

steel and are distinguished by their<br />

solid, robust and flexible design. The<br />

boiler combines ease of operation and<br />

maintenance with optimal efficiency.<br />

The boiler is designed with all necessary<br />

inspection doors and is constructed<br />

for gas or oil firing. Construction and<br />

production is according to EN12593,<br />

the Pressure Equipment Directive<br />

97/23/EG and CE marked. An independent<br />

authorized institution carries<br />

out quality approval at our factory.<br />

The ISO 9001 certification and internal<br />

quality control ensures excellent<br />

performance and longevity of service.<br />

The client receives an economical,<br />

environmentally friendly compact unit,<br />

supplied ready for installation.<br />

ESBI steam boiler<br />

The ESBI is a three-pass flame tube/<br />

flue gas tube boiler with an inner fully<br />

water-cooled reversal chamber with<br />

finned tube wall. The boiler consists<br />

of a cylindrical shell, two endplates,<br />

gusset stay supports, flame tube, gas<br />

reversal chamber with water cooled<br />

finned tube wall and two tube bank<br />

gas passes with low gas side resistance.<br />

The boiler is completely electrically<br />

welded and provided with all<br />

required inspection openings. The<br />

spacious flame tube with low thermal<br />

heat release results in excellent<br />

combustion and low emissions. Large<br />

water content and steam space provides<br />

steady state operation.<br />

Thermal insulation<br />

The boiler is fully insulated with<br />

120mm mineral wool insulation. The<br />

casing is made of 1mm thick stucco<br />

aluminum plate with neatly trimmed<br />

connections and cut-outs. The<br />

flue gas collector is also thermally<br />

insulated.<br />

Control panel<br />

The control panel is equipped with the<br />

required controls and indicators for<br />

control and supervision of the boiler<br />

and burner. Control switches, indicator<br />

lights and alarm signals are provided.<br />

The control panel is supplied to<br />

match the burner to be used.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

7

Products: <strong>Steam</strong> boilers<br />

ESBH <strong>Steam</strong> Boilers<br />

Low Capacities<br />

500 - 4,000 kg/h<br />

Technical details on pages 40 - 41<br />

High Capacities<br />

2,000 - 20,000 kg/h<br />

Technical details on pages 42 - 46<br />

Admissible maximum<br />

safety valve pressure<br />

• Standard pressures:<br />

10, 13 and 16 bar(g)<br />

• Savety valve pressures:<br />

11 and 14 bar(g)<br />

Higher pressures on request.<br />

The ECOTHERM high output steam<br />

boilers are made of high quality steel<br />

and are distinguished by their solid,<br />

robust and flexible construction, particularly<br />

by their operational ease, their<br />

easy maintenance and an optimal efficiency.<br />

The client receives an economical,<br />

environment friendly compact<br />

unit, ready for installation. The boilers<br />

are constructed for oil or gas firing.<br />

Boiler type ESBH<br />

The type ESBH classical 3 pass flame<br />

tube flue gas tube boiler consists of a<br />

cylindric shell, the two head plates, the<br />

flame tube including the back flue gas<br />

turning chamber with water cooled finned<br />

tube wall, the two flue gas passes<br />

and the fitting tube, placed either on<br />

the right (standard) or on the left. The<br />

boiler door is insulated and flue gas<br />

proof for burner mounting. The boiler<br />

is completely electrically welded and<br />

provided with all required inspection<br />

openings.<br />

The spacious flame tube with low<br />

thermal charges results in an excellent<br />

combustion and reduced emissions.<br />

The large water content secures<br />

an even burner running time and thus<br />

reduces the number of boiler starts.<br />

Thermal insulation<br />

The boiler is fully insulated with<br />

mineral wool insulation. The casing is<br />

made of structured aluminium plate.<br />

Fittings and out-cuts are properly rimmed.<br />

The flue gas collector is thermal<br />

insulated.<br />

High efficiency<br />

Due to the above technical facts an<br />

efficiency of up to 90%, respectively<br />

up to 95% with economizer, can be<br />

achieved with minimal space requirements.<br />

Thus continuos working costs<br />

are kept low. The sources of energy<br />

are used more efficiently and ECO-<br />

THERM spares the environment.<br />

Construction guiding,<br />

quality approval<br />

The boiler is designed with all necessary<br />

inspection doors. Construction<br />

and production is done according<br />

to the European Pressure Directive<br />

Equipment (PED) 97/23/EC, with CEconformity.<br />

The quality approval at ISO<br />

9001:2000 certification and the quality<br />

approval at our factory with our<br />

ECOTHERM quality performance<br />

department with works certificate guarantees<br />

the highest product quality.<br />

For installation and operation of the<br />

boiler the local laws and norms are to<br />

be respected.<br />

8 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Economizers<br />

Economizers<br />

Potential of savings for an<br />

economizer for a steam boiler<br />

• Boiler efficiency without<br />

ECO: 88% - 91%<br />

• Boiler efficiency with ECO:<br />

94% - 97%<br />

A boiler economizer is a heat exchanger<br />

device that captures the “lost or waste<br />

heat” from the boiler's hot stack gas<br />

which could not be used inside the boiler<br />

furnace (due to physical reasons;<br />

i. e. boiler water temperature). The economizer<br />

typically transfers this waste<br />

heat to the boiler's feed water or return<br />

water circuit, but it can also be used to<br />

heat up domestic water or other process<br />

fluids. Capturing this normally lost<br />

heat reduces the overall fuel requirements<br />

for the boiler. Less fuel equates<br />

to money saved as well as fewer emissions<br />

- since the boiler now operates<br />

at a higher efficiency. This is possible<br />

because the boiler feed water or return<br />

water is pre-heated by the economizer.<br />

Therefore the boiler's main heating circuit<br />

does not need to provide as much<br />

heat to produce a given output quantity<br />

of steam or hot water. Again fuel savings<br />

are the result. Boiler economizer<br />

improve a boiler's efficiency by extracting<br />

heat from the gases discharged.<br />

<strong>Steam</strong> boilers<br />

For steam boilers, the economizer is<br />

a typically heat exchanger through<br />

which the feed water is pumped. The<br />

flue gases, having passed through the<br />

main boiler area will still be hot.<br />

The energy in these flue gases is<br />

used to improve the thermal efficiency<br />

of the boiler.<br />

Feed water<br />

The feed water thus arrives in the<br />

boiler at a higher temperature, than<br />

it would be the case if no economizer<br />

was fitted. Less energy is then<br />

required to raise the steam. Alternatively,<br />

if the same quantity of energy is<br />

supplied, then more steam is raised.<br />

The result is a higher efficiency. In<br />

broad terms a 10°C increase in feed<br />

water temperature will give an efficiency<br />

improvement of about 2%.<br />

Shell boilers<br />

Optimizing energy consumption<br />

The heat output recovery from smoke<br />

gas is limited. At smoke gases from oil<br />

or gas firing plants there’s a steam content<br />

of 100 to 120 g/kg; the condensing<br />

point of this water content is situated at<br />

57°C. For heating up the feed water by<br />

an economizer it’s only possible to use<br />

the sensible heat (dry heat) because<br />

the feed water has to have a minimum<br />

temperature of 90°C - so it’s not possible<br />

to condense the smoke gases and<br />

to use the condensing energy too.<br />

FEED WATER TANK<br />

CHIMNEY<br />

ECONOMIZER<br />

BY-PASS<br />

STEAM BOILER<br />

On shell boilers the economizer is<br />

either installed directly at the boiler<br />

or - also possible - installed as a separate<br />

unit. The smoke gas coming<br />

from the last boiler smoke gas pass<br />

is guided into the economizer.<br />

Note: The smoke gas temperature<br />

leaving a normal boiler is about<br />

50°C to 80°C higher (full load<br />

and clean heating surfaces) then<br />

the saturated steam temperature.<br />

The minimum allowed smoke gas<br />

temperature (behind economizer)<br />

depends - mainly - to chimney design.<br />

For steam boilers operated at 10<br />

bar(g) the temperature levels which<br />

could be used at the economizer<br />

are about 250°C down to 140°C<br />

(smoke gas out from boiler compared<br />

to smoke gas out from eco)<br />

- which results in a fuel saving of<br />

about 5% comparing to boilers without<br />

economizer. The feed water<br />

temperature will rise from 105°C to<br />

round 135°C in that case.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

9

Products: Chimneys<br />

Chimneys<br />

CE-certified, double-wall, grimecombustion-resistant<br />

insulated<br />

chimney - respectively exhaust gas<br />

system - made of stainless steel by<br />

Jeremias, Germany.<br />

The chimney respectively exhaust gas<br />

plant is made of industrial, double-wall<br />

stainless steel system elements. It is<br />

used as an outer wall chimney as a<br />

standard but it is also suitable for assembling<br />

in buildings, as long as the<br />

system is floor-overlapping. But in this<br />

case the system has to be covered by<br />

a cored hole (which has to fulfill the<br />

fire protection requirements). This<br />

chimney can also be used for roof heating<br />

and for all connection piping.<br />

The exhaust gas plant is made of<br />

high-alloyed, austenitic stainless steel<br />

(AISI 316Ti). Its longitudinal seams<br />

are gas-shielded, arc welded and passivated<br />

via WIG.<br />

The production is externally controlled<br />

by an independent testing institute.<br />

The compliance of constant goods is<br />

checked by an internal control.<br />

The inner shell is made of 0.6-1.0 mm<br />

thick stainless steel (AISI 316Ti). The<br />

outer shell has got the same thickness<br />

at the stainless steel material number<br />

AISI 304. This material thickness offers<br />

perfect safeness against buckling<br />

and folding. The single elements are<br />

connected by plug-in sockets with<br />

overlying clamp fittings against scrolling<br />

and slipping.<br />

The inner shell of the system is able<br />

to extend freely as because of the<br />

construction of the single elements<br />

the inner shell cannot slip and consequently<br />

it remains centered without<br />

fixing on the outer shell.<br />

Thermal bridges between inner and<br />

outer shell are avoided because of<br />

this construction. The special mineral<br />

insulation (thickness 32mm) between<br />

inner and outer shell is high-temperature<br />

resistant and incombustible (material<br />

class A1 according to DIN 4102).<br />

Specifications<br />

• Thermal resistance class<br />

of the system: at reference<br />

temperature = 0.501 m²/K/W<br />

• Visible surface high-glossed<br />

(standard).<br />

• Possible designer surface:<br />

beamless, painted or grinded,<br />

as well as in copper<br />

• Inner diameter area of<br />

80 - 1,000 mm<br />

• Freestanding end above<br />

last wall holder: 3 m<br />

(up to DN 600)<br />

• Bigger diameters on request<br />

10 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Burners<br />

Gas, Oil and Dual Fuel Burners<br />

Gas burners<br />

Gas burners of ECOTHERM steam<br />

systems have been especially<br />

designed for industrial capacity<br />

ranges. The burners are noteworthy<br />

for their large capacity and<br />

operational ranges and numerous<br />

other interesting details:<br />

• Compliance with the most stringent directives and emission limits<br />

• Large capacity and operational ranges<br />

• Stable fan reference line - good combustion behaviour<br />

• Quiet operation<br />

• Burner housing can be hinged open<br />

• Easy to install, set and service<br />

• Automatic air shut off on burner shutdown<br />

Oil burners<br />

Oil burners are of the fully automatic<br />

pressure atomizing type. Their design<br />

has been carefully considered down<br />

to the smallest detail and has been<br />

proved successfully over and over<br />

again. They meet all the demands for<br />

safety, reliability and low cost servicing.<br />

The oil burners are type<br />

tested and have the following<br />

features:<br />

• Larger range of application<br />

• Automatic sequence of operations<br />

• Stable fan characteristics - good combustion results<br />

• Air damper closed on burner shutdown<br />

• Quiet operation<br />

• Complete pre-wired integral switchgear<br />

• Hinged burner casing<br />

• Combustion head can be withdrawn when the burner is hinged open<br />

• The design of the burner makes installation, adjustment and servicing easy<br />

Dual fuel burners gas/oil<br />

Dual fuel burners satisfy the requirements<br />

for operational safety, easy<br />

installation, and reliability. They operate<br />

economically and environmentally<br />

friendly. The oil side of the dual<br />

fuel burners comply with DIN EN 267.<br />

The gas burners and the gas side of<br />

dual fuel burners comply with DIN-EN<br />

676 and the gas appliance guidelines<br />

(90/396/EEC) and are EG type tested.<br />

• Large capacity and range of application<br />

• Automatic sequence of operations<br />

• Combustion chamber pre-purge<br />

• Safe flame monitoring<br />

• Stable fan characteristics - good combustion results<br />

• Quiet operation<br />

• Hinged burner casing<br />

• Simple installation, adjustment and servicing<br />

• Easily converted to other types of gas<br />

• Fuel change by manual or automatic change over.<br />

• Automatic air closure on burner shutdown<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

11

Products: Feed Water Tanks<br />

Feed Water Tanks & Deaerators<br />

Description<br />

The feedwater deaerating plant, consisting of the feedwater<br />

tank and the deaerator, removes dissolved gases such as<br />

oxygen, carbon dioxide and other non-condensable gases<br />

from boiler feedwater and makeup water.<br />

For the operation of steam boilers with high thermal load<br />

on the heating surfaces boiler feedwater must be treated<br />

and conditioned.<br />

The boiler feedwater must be free of hardening constituents<br />

in order to prevent the formation of scale on the boiler heating<br />

surfaces. The presence of dissolved oxygen and carbon<br />

dioxide causes severe corrosion of metal boiler parts. The<br />

feedwater deaerating plant is custom designed for each<br />

application and meets essential thermo dynamic requirements<br />

to achieve optimal performance.<br />

Technical details on pages 48 - 49.<br />

Benefits:<br />

• Sizes from 200 to 20,000 liters<br />

• Pressure resistant<br />

• Material: mild steel, stainless steel<br />

AISI 304 / 316 / Duplex SS<br />

• Completely preassembled unit<br />

• All valves, pumps, instruments are<br />

custom-designed according to<br />

steam boiler system<br />

Function<br />

The make-up water and return condensate enters the<br />

deaerator that is fitted with a series of tray compartments<br />

to provide maximum spilling. Heating steam is fed into the<br />

deaerator from below. The make-up water and return condensate<br />

are deaerated and flow directly into the feedwater<br />

tank, which is flanged to the deaerator. The feedwater tank,<br />

which is heated by means of a steam injector, heats up the<br />

feedwater to 105°C.<br />

The solubility of gases in water can be described by Henry<br />

Dalton‘s law of absorption which states that gas solubility in<br />

a solution decreases as the gas partial pressure above the<br />

solution decreases. This means that the gas solubility in a<br />

solution decreases as the temperature of the solution rises<br />

and approaches saturation temperature.<br />

The make-up water and return condensate is distributed<br />

over the series of trays and comes in direct contact with<br />

the heating steam. This process reduces the solubility of<br />

oxygen and carbon dioxide and removes these gases from<br />

the feedwater. The released gases work their way to the<br />

top of the vessel where they are vented from the deaerator<br />

via the vent line.<br />

A temperature-controlled heating system for warming up a<br />

cold feedwater tank is provided.<br />

Due to the fact that the feedwater temperature is above<br />

100°C enough net positive suction head (NPSH) is required<br />

to ensure that the weight of the column of water in the line<br />

exerts enough pressure at the feed water pump suction to<br />

prevent the formation of steam bubbles and therefore the<br />

water from cavitating. Therefore a support construction is<br />

required.<br />

12 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Feed Water Tanks<br />

PRESSURIZED FEED WATER TANK<br />

FLASH STEAM HEAT<br />

RECOVERY (OPTIONAL)<br />

MAKE-UP WATER<br />

VENT PIPE OUT<br />

OF BUILDING<br />

OVERFLOW TO DRAIN<br />

15<br />

12<br />

14<br />

2<br />

11<br />

FEED WATER TANK<br />

DISCHARGING AIR<br />

AND OXYGEN TO<br />

VENT out of building<br />

CONDENSATE RETURN<br />

1<br />

8<br />

10<br />

DEGASIFICATION<br />

PRESSURE<br />

REGULATION<br />

16<br />

8<br />

CONDENSATE RETURN<br />

9<br />

DRAIN<br />

17<br />

PRESSURE REDUCING STATION<br />

(OPTIONAL)<br />

FROM STEAM<br />

BOILER<br />

FEED WATER<br />

RETURN (OPTIONAL)<br />

13<br />

OPERATING PRESSURE<br />

0.2 - 0.3 bar (105°C)<br />

TS<br />

TI<br />

LEVEL<br />

CONTROL<br />

3<br />

TS<br />

7<br />

PRE-HEATING<br />

TEMPERATURE<br />

REGULATION<br />

4 DRAIN BOILER<br />

5 SAMPLE<br />

FEED<br />

WATER<br />

6<br />

WATER<br />

1 Feed Water Tank: preparing feed water for steam<br />

boilers, collecting condensate, adding chemicals,<br />

pre-heating of feed water.<br />

2 Pressurized Deaerator: removing oxygen and<br />

other gases, injection for fresh softened water,<br />

pressure control<br />

3 Level Control: to keep a constant water level in<br />

the tank a level control system is required. Also<br />

protection against low and high water is installed.<br />

4 Drain: for draining of the tank<br />

5 Boiler feed water: feed water supply connection to<br />

feed water pumps and boilers<br />

6 Sample water: connection to feed water sample<br />

cooler. Water quality needs to be checked daily<br />

7 Pre-heating of feed water to protect the boiler<br />

against too high temperature differences and heat<br />

tensions, feed water needs to be pre-heated by<br />

steam injection.<br />

8 Condensate return: collecting the condensate<br />

from different consumers, e. g. steam pipe draining<br />

points, heat exchangers, laundry machines.<br />

9 Pressure reducing station to provide exact<br />

needed pressure for pre-heating and degasification,<br />

steam pressure can be adjusted by pressure<br />

reducing station<br />

10 Degasification pressure regulation for removal<br />

of different gases from the feed water, a steam<br />

injection in deaerator is necessary. This injection<br />

should keep a constant tank pressure of about<br />

0.3 bar(g) for optimal degasification<br />

11 Discharging air and oxygen vent (out of<br />

building) removing port of waste gases. also<br />

a vapour heat exchanger (flash steam) can be<br />

installed on this port. (17)<br />

12 Safety valve high pressure protection valve<br />

opens when pressure increases.<br />

13 Feed water return (optional): in big boiler systems<br />

a 3-way valve control for feeding of steam boilers<br />

is proposed. In case of low load feed water will be<br />

returned to feed tank.<br />

14 Vacuum breaker: protection against negative<br />

pressure<br />

15 Overflow: protection against high water<br />

16 Manhole / handhole: will be provided for easy<br />

inspection and cleaning<br />

17 Flash <strong>Steam</strong> (Vapour): heat exchanger uses the<br />

“waste energy” to heat up make-up water before<br />

entering the deaerator<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

13

Products: Blow Down Coolers<br />

Blow Down Coolers & Flash Vessels<br />

<strong>Steam</strong> boilers must be blown down to remove contaminants,<br />

as a too high level will cause foaming and scaling<br />

of the boiler tubes. A build-up of solids at the bottom of the<br />

boiler could also have serious consequences. Most modern<br />

boilers are fitted with TDS controls to remove dissolved<br />

solids, and a blowdown valve that is opened at regular<br />

intervals to remove precipitated solids.<br />

Because the bottom blowdown valve is opened just a few<br />

seconds per day, it is not economical to recover the heat,<br />

yet water cannot be discharged to drain unless it is cool.<br />

Nowadays, blowdown vessels have replaced blowdown<br />

pits as the recommended way of cooling this water.<br />

Blowdown from TDS controls should ideally be connected<br />

to a heat recovery system inside a flash vessel. Where<br />

this is not practical, TDS blowdown may also be piped to a<br />

blowdown vessel.<br />

User benefits:<br />

• Three inlets as standard with dedicated bottom blowdown<br />

and TDS connection.<br />

• Fully complies with the requirements of the European<br />

Pressure Equipment Directive 97/23/EC.<br />

• Complete systems normally readily available from<br />

stock.<br />

• Quick and easy to install and maintain.<br />

For flash vessels an internal heat<br />

recovery system is provided.<br />

DISCHARGING AIR<br />

AND OXYGEN TO<br />

VENT out of building<br />

Important factors for sizing of blown<br />

down coolers & flash vessels:<br />

• Boiler pressure<br />

• Number of boilers<br />

• Duration of blow down<br />

• Blown down line size<br />

• Length of blow down line between the boiler and<br />

the blow down vessel<br />

• Blow down regime<br />

DRAIN<br />

14 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Water Treatment<br />

Water Softener<br />

Water filter<br />

Application<br />

Automatic volume-controlled softener producing soft water<br />

by means of ion-exchange. Particularly suitable in case<br />

of unsteady soft water consumption. Not recommended in<br />

case of fluctuating raw water hardness.<br />

Design<br />

• Ion-exchange tank made of glass-fibre reinforced<br />

plastic with PE<br />

• Inliner, filled with ion exchange resin on a layer of<br />

supporting gravel,<br />

• Brine tank with salt tray, supporting body, standpipe<br />

and brine valve and plastic cover,<br />

• Hose connecting the central distribution valve<br />

• Adapter with second ion-exchange vessel,<br />

• Central distribution valve made of red brass alloy, the<br />

controller and turbine water meter mounted on its top<br />

Chemical Dosing<br />

Technical details on page 50.<br />

Controller<br />

• Electrical connection 230 V ± 10 %, 50 - 60 Hz<br />

• Electricity supply for electronics and motored drive<br />

via adapter 230 V / 12 V (AC)<br />

• Energy consumption max. 10 VAC<br />

• Parameter storage in case of power failure:<br />

infinitely long<br />

• Programming the regeneration initiation:<br />

- amount (in litre or m³)<br />

- interval (in days) beginning with the end of the last<br />

regeneration<br />

- initiation time (for time and volume controlled<br />

operation)<br />

Chemical Dosing<br />

Water filter<br />

Hardness Control<br />

The chemical dosing is used to<br />

control the dosage of oxygen<br />

binder, prosphat and sulfite in<br />

the feed water of steam generators.<br />

The system basically consists<br />

of a solenoid diaphragm pump,<br />

mounted on a dosing tank for<br />

storage of the chemical dosage.<br />

The plant is individually designed<br />

according to the defined boiler<br />

parameters and is delivered fully<br />

pre-assembled.<br />

The water filter is used for the<br />

coarse filtration of fresh water<br />

and is mounted prior to entering<br />

the water treatment system.<br />

The size is determined by the<br />

required amount of fresh water,<br />

the characteristics of the fresh<br />

water and the size of the water<br />

softening plant.<br />

For the ease of cleaning an integral<br />

backwashing system of the<br />

filter is used.<br />

For automatic control of the<br />

water hardness for larger systems<br />

often a self-controlled water<br />

hardness monitoring unit is<br />

used.<br />

Thus, the steam system is always<br />

perfectly protected against<br />

too hard water.<br />

Alternatively, manual water test<br />

kits can be used, which require a<br />

continuous measurement of the<br />

water quality by the operator.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

15

Products: Water Treatment<br />

Reverse Osmose Systems<br />

The plant consist of:<br />

• High pressure membranes mounted on a<br />

stainless steel base frame<br />

• Checkvalve feedwater<br />

• Checkvalve cleansystem<br />

• Pressure switch as dry-run-protection<br />

• High pressure pump<br />

• Polysulfon/polyamid-membrane<br />

• Pressure gauges<br />

• Concentrate-, accumulation- and backflowvalve<br />

made of stainless-steel<br />

• Flowmeter permeate, concentrate and<br />

backflow<br />

• Control system with full automatic<br />

monitoring<br />

• Conductivity meter, digital display, operating<br />

hour meter<br />

• Adjustable limit value and alarm contact for<br />

low pressure and conductivity<br />

• Connection for niveau control, adjustable<br />

pressure- and interval flushing<br />

• Storage tanks made of stainless steel or<br />

plastic<br />

Reverse Osmosis is a process that is used to remove a<br />

wide range of salts to provide water of a high purity. Osmosis<br />

is a natural process involving fluid flow across a semipermeable<br />

membrane barrier. It is the process by which<br />

nutrients feed the cells in our bodies and how water gets to<br />

the leaves at the top of trees. Reverse Osmosis systems,<br />

in their basic form, consist of a pressure pump, housing<br />

and the membrane. Water is forced into the housing under<br />

pressure and the pure water (or permeate) is collected and<br />

passed to service.<br />

Reject water (or concentrate) is collected from another outlet<br />

and routed to drain, with a portion of the concentrated<br />

water recycled back to the inlet of the pump. This means<br />

that the portion of water sent to drain is kept to a minimum.<br />

The controller used on the RO system constantly monitors<br />

the quality of the permeate water and is also linked with<br />

safety controls on the system.<br />

RO plants must be supplied with softened, de-chlorinated<br />

or de-chlorinated anti scalent dosed water. A duplex softener<br />

is recommended for continuous operation.<br />

The size of the RO and choice of membrane will be determined<br />

by the permeate quantity required, feed water salinity<br />

and permeate quality expected. Low energy membranes<br />

allow the units to run at pressures around 10 to 13bar, and<br />

as such the pressure booster pumps required to generate<br />

the pure water are smaller, and the power consumption is<br />

reduced significantly.<br />

Additional recommended is also a storage tank which is<br />

used for reception of the pure-water.<br />

The size of this tank / these tanks should be in coordination<br />

with minimum and maximum RO water demand to ensure<br />

constant operation of the RO system.<br />

16 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Control Panels<br />

Control Panels<br />

Description<br />

The ECOTHERM control panels are all-in-one panels.<br />

They unify control and HMI in one compact<br />

unit. In the control cabinet, space is saved and<br />

the amount of wiring is reduced. Different processor<br />

variations and display sizes open a diversity<br />

of configuration possibilities. The user therefore<br />

acquires economic automation hardware. Decentralized<br />

solutions are simple to implement through<br />

the integrated VARAN interface. The software also<br />

follows the integration concept and simplifies programming.<br />

The TFT color display with touch screen<br />

provides high operating comfort for visualization.<br />

Master Control Panel<br />

The purpose of the master control panel is to organize<br />

the equipment of the whole boiler plan room.<br />

Each component with need of electrical supply is<br />

connected to this control panel and its actual operation<br />

mode is shown on a visual 2D/3D mimic diagram.<br />

Interfaces for BMS<br />

There exist several interfaces with existing BMS<br />

(building management systems) in order to<br />

share and/or transfer process data: RS232, CAN<br />

bus, ETHERNET and a USB port at the front side<br />

of the control panel.<br />

Control panels are individually and project-specificmanufactured<br />

by ECOTHERM.<br />

Main tasks:<br />

• Timed automatic changeover of the boilers<br />

• Automatic changeover of the boilers in case of failure<br />

cut out<br />

• Automatic start of 2nd boiler in case of high demand<br />

• Automatic changeover to standby pump in case of<br />

pump failure<br />

• Timed automatic run of standby pump - to avoid<br />

pump-block<br />

• On/Off switch for all plant room components<br />

• Operation/failure indication of main components on<br />

mimic diagram<br />

• BMS connection for failure signal<br />

• Remote control<br />

• Integrated panel cooling device<br />

• Custom designed hard- and software<br />

Highlights<br />

• Scalable: the right CPU for any requirement<br />

• Integrated: application software compatibility<br />

• Compact: space-saving installation in the<br />

control cabinet<br />

• Simple: one engineering tool for any task<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

17

Products: Condensate Return Station & Pressure Reducing Stations<br />

Condensate Return Stations<br />

Description<br />

The condensate recovery units are designed to handle hot<br />

condensate, which is commonly returned for use as boiler<br />

feedwater. They can handle high quantities at 98°C with<br />

pump delivery heads up to 30 - 35 meters. A unit comprises<br />

three main parts - receiver, pump/pumps and control panel.<br />

Standards<br />

This product fully complies with the requirements of the<br />

European Machinery Directive 98/37/EC, European Low<br />

Voltage Directive 72 / 73 / EEC and European Electromagnetic<br />

Compatibility Devices Directive 89/336/ EEC.<br />

This product is not a pressurized vessel and therefore<br />

does not need to comply with the European Pressure<br />

Directive 97/23/EC.<br />

• Receivers are manufactured of mild steel or SS<br />

304/316. All sizes are fitted with adequately sized vent,<br />

overflow, drain and inlet connections flanged to PN16 or<br />

screwed. A water level gauge and control is provided.<br />

• Pumps are designed for operation under conditions of<br />

low NPSH to handle hot condensate with the minimum<br />

of flooded suction. They are directly coupled to motors<br />

having class F insulation (class B temperature rise) and<br />

motor enclosure rating IP54 minimum.<br />

• Control: Receivers are fitted with solid state level<br />

control’s which provides on / off cascade pump operation.<br />

The control panel incorporates electrical equipment<br />

suitable for 400 volt, 3 phase, 50 Hz, 4 wire supply.<br />

Control equipment is installed in a pre-wired IP54 rated<br />

metal enclosure. Connections for BMS interface are<br />

provided to monitor pump run or tripped condition.<br />

• Pump fitting: The motor and pumps are mounted<br />

under the receiver with over size suction inlet pipework<br />

and isolation valves. The pump discharge outlet is fitted<br />

with a non return valve and a pressure gauge.<br />

Technical details on page 51.<br />

Pressure Reducing Stations<br />

It is more efficient and economic to<br />

produce steam at high pressures<br />

ready for delivery through the distribution<br />

system. This may mean that the<br />

pressure needs to be reduced prior to<br />

the point of use or for different parts<br />

of the system. A reliable method of<br />

providing pressure reduction is to use<br />

a pilot operated pressure reducing<br />

valve station.<br />

Every pressure reducing station is<br />

custom designed according to<br />

required steam flows and pressures.<br />

18 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Blow Down Systems, Control Units, <strong>Steam</strong> Boilers<br />

Automatic Blow Down Systems<br />

The automatic boiler blow down<br />

system allows the built up of sludge in<br />

the bottom of the boiler to be flushed<br />

regulary by a timer controller which<br />

cyclically opens a pneumatically<br />

actuated blow down valve. Blow down<br />

interval and duration are to be set<br />

by the user according to the water<br />

characteristics. The system avoids<br />

wasted heat and repetition or<br />

omission which occurs with manual<br />

blow down.<br />

Blow Down<br />

Valve<br />

Blow Down<br />

Vessel<br />

Automatic TDS Control Units<br />

Sensor Tip with<br />

Conductivity Probe<br />

The TDS automatic control system<br />

limits the level of dissolved salts and<br />

minerals contained in the boiler water<br />

to the allowed level, which avoids<br />

carry over due to excessively high TDS<br />

levels and minimizing the amount of<br />

blowdown required.<br />

The system continuously measures,<br />

just below the water surface level,<br />

the waters electrical conductivity and<br />

compares with the set point. If the<br />

measurement is higher the TDS valve<br />

is opened until the measured value<br />

drops below the set point.<br />

Blow Down<br />

Control Valve<br />

Level Control for <strong>Steam</strong> Boilers<br />

To control and to keep a constant water<br />

level in a boiler, a level control is<br />

used, which gives a signal to the controler<br />

to switch on/off the feed water<br />

pump.<br />

Essential are also level safety devices<br />

as low and high level cut off systems<br />

and gives alarms.<br />

Low level systems consisting of two<br />

independent level probes connected<br />

to two distinct level relays. They provide<br />

a visual and acoustic alarm in<br />

case the water level falls below a preset<br />

value and permanently stops the<br />

boiler, which only is able to operate<br />

again after a manual reset.<br />

At a high level system there is also<br />

an acoustic and visual alarm in case<br />

the boiler gets over flooded. Then the<br />

boiler feed water pump is stoped until<br />

the water level returns to the normal<br />

condition.<br />

Feedwater<br />

Pump<br />

Conductivity<br />

Probe<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

19

Products: <strong>Steam</strong> Accessories<br />

Valves, instruments & steam accessories<br />

Whether shut off valves, pressure<br />

regulation valves, steam traps,<br />

air vents, safety valves, measuring<br />

devices or gauges are required<br />

- ECOTHERM can tailor your<br />

selected equipment to your specific<br />

requirements.<br />

In coorporation with well-known and<br />

leading suppliers for steam equipment<br />

ECOTHERM can supply the parts you<br />

need for your system.<br />

<strong>Steam</strong> Flow Metering<br />

For the universal measurement of the<br />

volume/mass flow of gases, steam<br />

and liquids an individually selected<br />

flow meter can be used.<br />

Maximum fluid temperature ranges<br />

from –200°C up to +400°C, and pressure<br />

ratings up to PN250 are possible.<br />

There is also no maintenance because<br />

no moving parts are required.<br />

Trough the inbuilt flow measurement<br />

computer the software initial settings<br />

save time and costs.<br />

The high resistance to vibrations,<br />

temperature shocks and water hammer<br />

makes the flow meter very robust.<br />

Feed Water Pumps<br />

A feed water pump is considered to<br />

guarantee continuous feed water flow<br />

to the steam boilers.<br />

In case of fault of the feed water<br />

pump, a second reserve pump is<br />

supplied, installed in parallel to the<br />

operating one.<br />

For the protection of the pumps, low<br />

water control in feed water tank and<br />

strainers are installed.<br />

For easy maintenance and servicing<br />

each pump can be removed by<br />

closing the shut off valve before and<br />

after each pump.<br />

To guarantee non cavidation on the<br />

feed water pump impeller, every pump<br />

is individually designed according to<br />

the steam plant specification.<br />

20 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: <strong>Steam</strong> Headers, Separators, Sample Coolers<br />

<strong>Steam</strong> Headers<br />

ECOTHERM steam headers are<br />

individually designed according<br />

to the maximum boiler load.<br />

Any pipe connection and steam<br />

distribution can be considered in<br />

design stage. Every steam header is<br />

equiped with one or two relay points<br />

according to the size of the header. All<br />

headers are manufactured according<br />

to European pressure directive (PED).<br />

<strong>Steam</strong> Separators<br />

Sample Coolers<br />

The ECOTHERM steam separator<br />

provides the total<br />

solution for all pipelines carrying<br />

steam, air or gas where water droplets<br />

are in suspension.<br />

The purpose of steam separators is<br />

to collect small droplets of water and<br />

separate them from the steam in the<br />

pipes.<br />

The ECOTHERM baffle type separator<br />

is designed to achieve this separation<br />

by having an internal volume many<br />

times greater than the inlet pipework.<br />

The flow velocity of the steam, air<br />

or gas is significantly reduced as it<br />

enters the body. The relatively heavy<br />

water droplets impact on the internal<br />

baffles and are then directed to the<br />

separator drain connection and removed<br />

from the system using either a<br />

steam trap, or when used on air or gas<br />

distribution system, a liquid drainer.<br />

The ECOTHERM baffle type separator<br />

is a highly efficient product, operating<br />

over a wide velocity range, leading to<br />

improved system performance.<br />

Technical details on page 53.<br />

ECOTHERM sample coolers are used<br />

to take samples of water or steam from<br />

boilers at high temperature and pressure.<br />

The counter-current flow through<br />

the shell and coil condenses the steam<br />

and cools hot fluids efficiently to enable<br />

safe sampling. When hot pressurized<br />

liquids are being cooled the sample<br />

cooler prevents “flashing-off” which<br />

can be dangerous and will result in an<br />

inaccurate sample. By utilising corrosion<br />

resistant materials for the cooler,<br />

contamination is minimized, and<br />

service life maximized.<br />

Clear results<br />

The boiler and feed water has to be<br />

analyzed daily. The sample cooler<br />

helps to cool the hot boiler and feed<br />

water down to a safe temperature.<br />

Only cooled samples will give clear<br />

results.<br />

Description<br />

The hot water from boiler and feed<br />

water tank is conducted through a<br />

stainless steel cooling serpent. This<br />

serpent is girdled with cold water in a<br />

small stainless steel vessel.<br />

Technical details on page 54.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

21

www.ecotherm.com<br />

Individual Turnkey <strong>Steam</strong> <strong>Solutions</strong><br />

Individual Turnkey <strong>Steam</strong> <strong>Solutions</strong><br />

<strong>Steam</strong> systems are complex and individual.<br />

On the one hand a lot of different<br />

components have to be used.<br />

All these components need to be optimally<br />

coordinated with each other<br />

to ensure functionality and perfect<br />

efficiency right from day one. On the<br />

other hand steam systems operate<br />

with high pressures. Thus a failure<br />

can really be very dangerous for the<br />

staff operating the system as well as<br />

for the complete building. Therefore<br />

ECOTHERM offers complete individual<br />

turnkey solutions. The services<br />

range from design, 3D visualization,<br />

project management, over manufacture,<br />

pre-assembly, pre-wiring<br />

and testing to shipping, commissioning,<br />

supervision and maintenance.<br />

Experienced ECOTHERM engineers<br />

ensure that your system operates<br />

stable, save, reaches the desired output<br />

and they train your staff how to<br />

monitor and control the most important<br />

parameters of the system.<br />

Premium quality of the products and<br />

premium service during the whole project<br />

is the minimum you should claim<br />

for your individual steam system.<br />

Find the products and services<br />

included in an ECOTHERM turnkey<br />

system on the following pages.<br />

Hot Water, <strong>Steam</strong> and Solar Systems<br />

2 Turnkey <strong>Solutions</strong><br />

Find more information in our<br />

brochure “Turnkey <strong>Solutions</strong>”.<br />

22 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Wiring, Piping<br />

(Pre-)Wiring<br />

Turnkey system from ECOTHERM<br />

meet highest quality demands. Therefore<br />

the system is pre-assembled<br />

and pre-wired in the headquarters in<br />

Austria. The complete system is fully<br />

tested and approved according to<br />

European standards.<br />

After shipping the pre-wired components<br />

can be installed very quickly.<br />

Small systems usually can go into<br />

operation within a couple of days.<br />

(Pre-)Piping<br />

Small systems are delivered including<br />

pre-piping as a standard. For larger<br />

turnkey systems ECOTHERM offers<br />

the option to individually manufacture<br />

all necessary pipes, to pre-assemble<br />

and test the complete system including<br />

the piping in the production facility<br />

in Austria and then to ship the piping<br />

in units which can easily be mounted<br />

at construction site. The complete<br />

piping is 3d visualized with CAD<br />

design prior to manufacture. The<br />

welding is done accordining to<br />

ISO 3834-2 : 2005 certification.<br />

Pipe Supports<br />

Pipe shoes and supports from Sikla<br />

in Austria have become the widely<br />

recognized “state-of-the-art” in plant<br />

engineering’s pipe installations. A modular<br />

kit gives all the freedom at the<br />

installation in the plant room. You will<br />

capitalize on simplified stock logistics.<br />

Through the combination of base<br />

unit (skid) with a set, only one type<br />

is stocked and the variations can instantly<br />

be generated depending on<br />

demand. All pipe supports and pipe<br />

shoes have a safety-relevant function<br />

within an operating plant.<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

23

High Capacity Clean <strong>Steam</strong> Generators<br />

Clean steam generators are used wherever plant steam,<br />

generated in fired steam boilers is not suitable. Due to the<br />

necessity of chemical dosing and the black material of the<br />

fired steam boilers, plant steam is not applicable for hygienic<br />

purposes. The ECOTHERM clean steam generator is<br />

entirely made of stainless steel to suit hygienic purposes<br />

like sterilizer units in hospitals or cleaning the stainless<br />

steel pipes of beverage & food industries. It is a compact,<br />

skid mounted unit ready for easy installation at site.<br />

Standard equipment<br />

• Clean <strong>Steam</strong> vessel made of AISI 316 Ti or duplex<br />

stainless steel<br />

• Pressure / temperature controlled<br />

• <strong>Steam</strong> trap set with ball float valve<br />

• Centrifugal feed water pump<br />

• Fully automatically control panel<br />

• Blow down vessel, stainless steel<br />

• Sample cooler, stainless steel<br />

• Safety and control utilities<br />

• Design and manufacturing according to PED 97/23/EC<br />

Capacities from 250 - 4,000 kg/h as a<br />

standard. Higher capacities on request.<br />

<strong>Steam</strong> generation:<br />

• by heat exchanger (plant steam / clean steam)<br />

• by electric heating bundle<br />

Optional equipment<br />

• with <strong>Steam</strong> Flow meter<br />

• with PRV-unit<br />

• with steam header<br />

Applications:<br />

• Sterilizers for healthcare<br />

• Sterilize in place (SIP) for<br />

food and beverages<br />

• Direct injection into the product for<br />

pharmaceuticals<br />

• Clean room humidification for<br />

biotechnology<br />

• Operating environments for<br />

electronics<br />

• Laboratories for brewing<br />

• Humidifiers<br />

Description:<br />

The clean steam is generated by plant steam or by electrical<br />

energy. The clean steam generator is loaded with softened<br />

and heated water (without lime, PH-neutral conductivity,<br />

0–30 μS). This water will become clean steam. The level<br />

control guarantees an optimized level of water and causes<br />

an alarm if the water level falls below the alarm switch.<br />

The pressure of the clean steam is controlled according to<br />

the requirement by regulation valve.<br />

A conductivity measuring unit regulates the level of minerals<br />

in the water to protect the vessel.<br />

To avoid any dirt inside the clean steam generator and to<br />

guarantee a high quality of water and a long life of the vessel<br />

is installed a blow down valve which is controlled automatically.<br />

The blow down cooler cools the hot water of the blow down<br />

to 40°C to drain the water and to avoid burnings.<br />

The clean steam generators can be manufactured completely<br />

pre-piped and wired, mounted on a stainless steel<br />

support frame.<br />

Technical details on page 52.<br />

24 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Clean <strong>Steam</strong> Generators<br />

PLANT STEAM<br />

RO WATER<br />

SUPPLY<br />

7<br />

OVERFLOW TO DRAIN<br />

FEED WATER TANK<br />

DISCHARGING AIR AND<br />

OXYGEN TO VENT out of<br />

building<br />

6<br />

9<br />

CONDENSATE RETURN<br />

14<br />

PRE-HEATING<br />

TEMPERATURE<br />

REGULATION<br />

8<br />

VENT PIPE OUT<br />

OF BUILDING<br />

5<br />

STEAM<br />

SUPPLY<br />

4<br />

PRESSURE CONTROL<br />

PT P PL<br />

LS<br />

SOFTENED WATER<br />

SUPPLY<br />

OPERATING PRESSURE<br />

0 bar (95°C)<br />

DRAIN<br />

12<br />

TS<br />

TI<br />

MASTER CONTROL<br />

PANEL<br />

LEVEL<br />

CONTROL<br />

BOILER<br />

FEED<br />

WATER<br />

13<br />

10<br />

WATER<br />

SAMPLE<br />

COOLER<br />

TS<br />

11<br />

16<br />

CLEAN STEAM GENERATOR<br />

TI<br />

HIGH PRESSURE SURFACE<br />

BLOW DOWN<br />

TDS CONTROL<br />

3<br />

LEVEL CONTROL<br />

10<br />

1<br />

TI<br />

18<br />

SOFTENED WATER<br />

SUPPLY<br />

17<br />

2<br />

12<br />

TS<br />

15<br />

FEED WATER PUMP UNIT<br />

OVERFILL PROTECTION<br />

1 Clean <strong>Steam</strong> Generator: generation of clean,<br />

sterile steam by using high quality stainless steel<br />

materials. <strong>Steam</strong> generation by heat exchanger<br />

application.<br />

Consisting of stainless steel tank, removable<br />

heating bundle and all required connections for<br />

safety and control.<br />

2 High pressure bottom blown down control:<br />

flushing of the boiler bottom where sludge is created<br />

by timer controlled blow down valve.<br />

3 High pressure surface blown down control<br />

(TDS control) continuously measurement of water<br />

conductivity just below the water surface level. If the<br />

value is too high, valve opens until the measured<br />

value drops below the set point.<br />

4 Pressure control: pressure will be setted<br />

mechanical (by mechanical pressure control valve)<br />

or electrical by pressure transmittor (control panel)<br />

and electrical operated valve.<br />

5 <strong>Steam</strong> supply: clean steam outlet port from clean<br />

steam generator<br />

6 Feed water tank: preparing feed water for steam<br />

boilers, collecting condensate, pre-heating of feed<br />

water.<br />

7 Overflow: protection against high water<br />

8 <strong>Steam</strong> separator unit to prevent steam regulation<br />

valves from condensate, steam will be separated by<br />

using steam separator and draining unit<br />

9 Discharging air and oxygen vent (out of<br />

building): removing port of waste gases.<br />

10 Level control: to keep a constant water level in<br />

the tank a level control system is required. Also<br />

protection against low an high water is installed.<br />

11 Pre-heating of feed water to protect the boiler<br />

against to high temperature differences and heat<br />

tensions, feed water needs to be pre-heated by<br />

steam injection.<br />

12 Drain for draining of the tank<br />

13 Boiler feed water: feed water supply connection to<br />

feed water pumps and boilers<br />

14 Condensate return collecting the condensate<br />

from different consumers, e. g. steam pipe draining<br />

points, heat exchangers, laundry mashines.<br />

15 Blown down cooler to cool down the hot water<br />

from surface and bottom blow down outlets.<br />

16 Water sample cooler for daily analysis of feed<br />

water and boiler water, hot water samples have to<br />

be cooled down by water sample cooler.<br />

17 Feed water pump unit vertical multistage<br />

centrifugal feed water pump which feeds the steam<br />

generator with feed water. Pump is designed<br />

according to maximum steam pressure and flow<br />

capacity of steam boiler.<br />

18 Master Control panel entire independent steam<br />

generation regulation and safety devices control<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

25

Products: Clean <strong>Steam</strong> Generators<br />

Smart <strong>Steam</strong> Generators<br />

(160 - 560 kg/h)<br />

• Oil or gas fired<br />

• Vertical evaporation system<br />

• Without coil / with centrifugal pump<br />

• Particulary low-maintenance and<br />

energy-efficent<br />

In contrast to a steam generator (with<br />

heating-coil and piston pump), the<br />

system works as follows:<br />

• Controlled by the water level<br />

measured inside of the evaporation<br />

system, the centrifugal pump refills<br />

the feed water via the economizer.<br />

• The burner is controlled by steam<br />

pressure.<br />

• A multiplepass pipe transfers the<br />

burnt-gas heat through the evaporation<br />

system and to the water inside.<br />

• Additionally, the economizer transfers<br />

residual heat from the exhaust<br />

air to the feed water stream.<br />

• The special inner structure of the<br />

evaporation system provides best<br />

dry steam results.<br />

Technical details on page 47.<br />

High energy efficiency<br />

• Up to 97% combustion efficiency<br />

• Condensing heating technology (More than 100% efficiency possible with<br />

optional use of second economizer)<br />

• Minimal loss of heat in stand-by-mode<br />

• High steam quality (little entrainment of water)<br />

• 3- to 5-pass boiler technology<br />

Robust and low-maintenance<br />

• Robust pressure vessel with up to 8mm wall thickness<br />

• Integreated maintenance-free centrifugal pump<br />

• State-of-the-art, interchangeable standard burner<br />

• Gentle heating procedure within 8 minutes<br />

• Safety-related equipment exceeding the requirements of PED 97/24/EC<br />

• Components mainly serial products of established suppliers<br />

Easy<br />

• Menu-driven, easy operation by full-text touchscreen<br />

• Simple start / stop procedure by remote control, timer or manual<br />

• Parallel management of multiple boilers possible as an option<br />

• Operating pressure up to 11 bar(g).<br />

26 ECOTHERM <strong>Steam</strong> <strong>Solutions</strong>

Products: Smart <strong>Steam</strong> Generators<br />

Multiple <strong>Steam</strong> Boiler Plants<br />

(up to 2,240 kg/h)<br />

If a steam volume in excess of 560 kg/h<br />

is required or if near 100% safety in<br />

steam supply by redundancy is required,<br />

multiple steam plants should be chosen.<br />

Multiple steam plants usually use a joint<br />

water supply and joint blow-off vessel.<br />

Only several steam boiler are set up in<br />

parallel.<br />

In multiple steam plants, the capacity<br />

is adjusted to demand by a boiler<br />

sequence switching mechanism.<br />

Your advantages<br />

• Vertical pressure vessel<br />

• No heating-coil<br />

• Especially low maintenance and high energy efficiency<br />

Electric Clean <strong>Steam</strong> Generators for low capacities<br />

• Boiler and components made of high quality stainless steel<br />

• High clean steam quality<br />

• Capacity from 20kW to 80kW<br />

• Simple operation and simple maintenance<br />

• Innovative design for large water surface leads to dry steam<br />

• Integrated separator keeps the steam dry even at low pressure<br />

• Immediate load adjustment by electric power control<br />

• Operating pressure up to 12 bar<br />

• Modulating balancing control of the heating rods minimizes<br />

heating rod strain and extends the service life of the electrical<br />

components<br />

• All components are made of high-quality stainless steel and<br />

therefore offer extremely long service lifes<br />

• Low space requirements due to compact build<br />

• Rolls for simple transport or frequent relocation<br />

Technical details on page 53.<br />

• Ideal for: food/beverage producers, lab technology, hospitals,<br />

medical/pharmaceutics industry<br />

ECOTHERM <strong>Steam</strong> <strong>Solutions</strong><br />

27

Model EDRE<br />

Products: Smart <strong>Steam</strong> Generators<br />

Vapour Heat Exchangers<br />

The ECOTHERM vapour heat exchanger is used for:<br />

• Pre-heating of boiler feed water<br />

• Condensate relief<br />

• Degasification of fresh softened water and condensate<br />

• Flash steam heat recovery<br />

For this process, thermal degasification, steam is used which deaerates the<br />

gases (N 2<br />

, O 2<br />

, CO 2<br />

) out of building. Hence there is energy lost on deaerator.<br />

This “lost energy” can be used for pre-heating of cold softened water or domestic<br />

cold water.<br />

Technical details on page 54.<br />

ECOTHERM High Capacity Water Heaters<br />

ECOTHERM “EDRE” high capacity<br />

water heater with storage tank.<br />

Description<br />

High capacity water heater for steam/<br />

water operation. External heat exchanger<br />

with patented free floating<br />

turbulator rods for increased efficiency<br />

and self cleaning effect. Perforated<br />

stainless steel safety cover.<br />

Fibre-fleece insulated hot water storage<br />

tank, upright standing. All parts<br />

in contact with water are made entirely<br />

of stainless steel AISI-316Ti /<br />

duplex. “Anti-Legio” design fully compliant<br />

with European anti-legionella<br />

recommendations. Microprocessor<br />

controlled modulating 2 way condensate<br />

control valve on primary circuit<br />

return line, secondary circuit circulating<br />

pump, 4 temperature sensors for<br />

pre-heat start-up, heating cycle start,<br />

heating cycle stop and anti-fouling<br />

cooling cycle. Microprocessor control<br />

unit mounted on gantry with volt<br />

free output signals for boiler request<br />

and alarm. Input signal for remote<br />

operation. All components are preassembled<br />

and wired. Simple on-site<br />

assembly.<br />

Storage tank insulation<br />

Fibre-fleece insulation with a robust<br />

PP exterior shell, patented aluminum<br />

closure strips and patented self-fixing<br />

covering rossettes, fire protection<br />

class B2 (B1 upon request).<br />

Output performance<br />

• Output rating: 100 - 2,000 kW<br />

• Storage capacity: from 300 up to 5,000 liters or larger<br />

• Peak hot water output: 1,800 - 35,900 liters / hour at 60°C<br />

(Higher output and storage capacities available on request)<br />

steam / water<br />

100 - 2,000 kW<br />

3<br />

Model EF<br />

water / water<br />

40 - 350 kW<br />

High Capacity<br />

Water Heaters<br />

Model EHRE<br />

water / water<br />

100 - 1,000 kW<br />

www.ecotherm.com<br />

Find more information in our brochure<br />

“High Capacity Water Heaters”.<br />

Special features<br />