light! 004 | The car of the future

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MANUFACTURING<br />

BCB<br />

Process and quality control<br />

Process control involves measuring <strong>the</strong> temperature<br />

and identifying <strong>the</strong> shape <strong>of</strong> certain products in a production<br />

line, so that <strong>the</strong>y conform to specifications.<br />

Artificial vision can detect a production problem, but<br />

not <strong>the</strong>rmal irregularities. Indeed, <strong>the</strong>rmography provides<br />

much more information to production specialists<br />

and decision makers, adding a new dimension to<br />

computer vision.<br />

Many automobile manufacturers use <strong>the</strong>rmographic<br />

cameras for quality control. New vehicles undergo<br />

a multitude <strong>of</strong> tests for this purpose. Typical applications<br />

include inspection <strong>of</strong> rear window heating,<br />

heated seats, exhaust covers, air conditioning outlets,<br />

etc. <strong>The</strong>rmography is essential in durability and<br />

validation tests.<br />

Hot forming stamping<br />

and forging<br />

<strong>The</strong> hot forming process is based on combining a<br />

deformation operation <strong>of</strong> <strong>the</strong> base material (sheet<br />

or billet) at high temperature with subsequent<br />

quenching treatment. While hot, <strong>the</strong> material is<br />

more ductile and <strong>the</strong> piece is deformed with smaller<br />

forces. Subsequent rapid cooling gives it its highstrength<br />

martensitic structure. <strong>The</strong> microstructure<br />

and final properties <strong>of</strong> <strong>the</strong> manufactured part are<br />

strictly linked to a good control <strong>of</strong> <strong>the</strong> temperatures,<br />

times and deformations applied.<br />

Large temperature differences in <strong>the</strong> part or in <strong>the</strong><br />

die during <strong>the</strong> process lead to <strong>the</strong> appearance <strong>of</strong><br />

non-homogeneous deformations that can put <strong>the</strong><br />

manufactured part out <strong>of</strong> tolerance. To avoid this,<br />

<strong>the</strong> <strong>the</strong>rmal monitoring <strong>of</strong> hot forming cycles is required<br />

to evaluate <strong>the</strong> evolution <strong>of</strong> <strong>the</strong> temperature<br />

in <strong>the</strong> part before and after deformation, as well as<br />

<strong>the</strong> correct cooling <strong>of</strong> <strong>the</strong> die.<br />

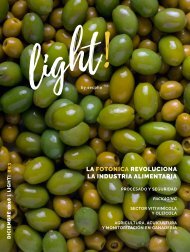

Quality control for <strong>car</strong><br />

components<br />

A reduction in <strong>the</strong> failure rate <strong>of</strong> electronic vehicle<br />

components is essential. <strong>The</strong> only way to guarantee<br />

this reduction is to check each component individually<br />

<strong>the</strong>reby <strong>of</strong>fering 100% guaranteed quality control.<br />

<strong>The</strong>rmography allows electronic component<br />

manufacturers to detect hot spots, which is an indication<br />

<strong>of</strong> defective products.<br />

Additive manufacturing<br />

Also known as 3D printing, it allows you to create<br />

pieces directly from a digital model without <strong>the</strong> need<br />

for traditional subtractive machining tools and with<br />

minimal geometric limitations. Heat is an integral part<br />

<strong>of</strong> <strong>the</strong> additive manufacturing process and needs to<br />

be monitored to detect phenomena that have a direct<br />

effect on both <strong>the</strong> dimensional and mechanical<br />

quality and performance <strong>of</strong> <strong>the</strong> final product. <strong>The</strong><br />

diagnosis <strong>of</strong> <strong>the</strong>rmal stress or distortions using typical<br />

contact sensors such as <strong>the</strong>rmocouples, RTDs<br />

or <strong>the</strong>rmistors, is complicated or even impossible.<br />

<strong>The</strong>rmographic cameras help to study <strong>the</strong> process<br />

and its <strong>the</strong>rmal properties, correlating temperatures<br />

measured during <strong>the</strong> process with quality parameters<br />

for <strong>the</strong> finished product. With <strong>the</strong> help <strong>of</strong> <strong>the</strong>rmography<br />

it is possible to identify porosity, delamination,<br />

retraction, poor surface finish or dimensional defects.<br />

Comparison <strong>of</strong> <strong>the</strong>rmal dissipation between electronic circuits<br />

40 <strong>light</strong>! by secpho