September 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Exposure<br />

SPONSORED BY<br />

to Dust<br />

EXTRACTION PLAN!<br />

The experts at EJOT UK discuss a new solution to protect<br />

against airborne concrete dust and debris contamination.<br />

The airborne distribution of dust and debris<br />

created from a variety of construction site<br />

activities has become a priority focus for<br />

the UK Government’s Health and Safety Executive<br />

(HSE). For example, the HSE’s CIS69 document<br />

provides guidance on choosing, using and<br />

maintaining on-tool extraction to control<br />

construction site dust. This dust may contain<br />

some very fine dust called respirable crystalline<br />

silica (RCS) and exposure to<br />

RCS dust can be the cause<br />

of varying levels of health<br />

1<br />

problems – many serious.<br />

This and other documents<br />

also highlight the legal<br />

responsibilities for<br />

employers to either prevent<br />

or adequately control<br />

‘worker exposure’ to high<br />

levels of dust created by a<br />

variety of tasks that include<br />

cut-off saws, grinders,<br />

breakers and sanders.<br />

Logical then, that SDS<br />

drilling into concrete, brick<br />

and block substrates<br />

presents the same potential<br />

hazards.<br />

What is SDS drilling?<br />

Our German colleagues will<br />

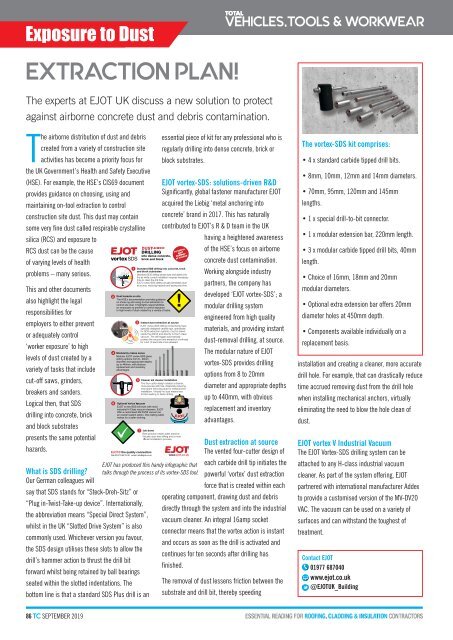

Modularity makes sense<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Optional<br />

Vortex Vacuum<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

say that SDS stands for “Steck-Dreh-Sitz” or<br />

“Plug in-Twist-Take-up device”. Internationally,<br />

the abbreviation means “Special Direct System”,<br />

whilst in the UK “Slotted Drive System” is also<br />

commonly used. Whichever version you favour,<br />

the SDS design utilises these slots to allow the<br />

drill’s hammer action to thrust the drill bit<br />

forward whilst being retained by ball bearings<br />

seated within the slotted indentations. The<br />

bottom line is that a standard SDS Plus drill is an<br />

2<br />

4<br />

6<br />

DUST-FREE<br />

DRILLING<br />

into dense concrete<br />

brick and block<br />

Standard SDS drilling into concrete, brick<br />

and block substrates<br />

Standard SDS drilling sends dust and debris into<br />

the air while correct installation requires necessary<br />

time to clean the drill hole.<br />

EJOT vortex-SDS drilling virtually eliminates dust<br />

at source, reducing hazards and<br />

saving site time.<br />

!<br />

Dust hazards on site<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

EJOT® the quality connection<br />

Call 01977 68 70 40 email: info@ejot.co.uk<br />

3<br />

5<br />

7<br />

essential piece of kit for any professional who is<br />

regularly drilling into dense concrete, brick or<br />

block substrates.<br />

EJOT vortex-SDS: solutions-driven R&D<br />

Significantly, global fastener manufacturer EJOT<br />

acquired the Liebig ‘metal anchoring into<br />

concrete’ brand in 2017. This has naturally<br />

contributed to EJOT’s R & D team in the UK<br />

having a heightened awareness<br />

e,<br />

POWERFUL<br />

DUST<br />

REMOVAL<br />

AT<br />

T SOURCEE<br />

Instant t dust extraction at source<br />

EJOT vortex-SDS drilling components have<br />

specially ly designed carbide tips, specifically<br />

for SDS S extraction systems. Dust is drawn<br />

inside the drill bit and directl<br />

ly to the H-class<br />

vacuum. The drill trigger automatically<br />

powers the vacuum and extraction continues<br />

for a full 10 seconds once re<br />

eleased.<br />

Cleaner er air<br />

, cleaner installation<br />

The four-cutter design creat tes a cleaner,<br />

more precise drill hole, drastically reducing<br />

time spent removing dust for metal anchor<br />

installation. ation. Virtually no dust means less<br />

friction leading to faster drilling.<br />

Job done!<br />

Best practice means safer practice.<br />

Virtua ally dust-free drilling and a more<br />

efficient ent installation process.<br />

www.ejot.co.uk<br />

EJOT has produced this handy infographic that<br />

talks through the process of its vortex-SDS tool.<br />

of the HSE’s focus on airborne<br />

concrete dust contamination.<br />

Working alongside industry<br />

partners, the company has<br />

developed ‘EJOT vortex-SDS’; a<br />

modular drilling system<br />

engineered from high quality<br />

materials, and providing instant<br />

dust-removal drilling, at source.<br />

The modular nature of EJOT<br />

vortex-SDS provides drilling<br />

options from 8 to 20mm<br />

diameter and appropriate depths<br />

up to 440mm, with obvious<br />

replacement and inventory<br />

advantages.<br />

Dust extraction at source<br />

The vented four-cutter design of<br />

each carbide drill tip initiates the<br />

powerful ‘vortex’ dust extraction<br />

force that is created within each<br />

operating component, drawing dust and debris<br />

directly through the system and into the industrial<br />

vacuum cleaner. An integral 16amp socket<br />

connector means that the vortex action is instant<br />

and occurs as soon as the drill is activated and<br />

continues for ten seconds after drilling has<br />

finished.<br />

The removal of dust lessens friction between the<br />

substrate and drill bit, thereby speeding<br />

The vortex-SDS kit comprises:<br />

• 4 x standard carbide tipped drill bits.<br />

• 8mm, 10mm, 12mm and 14mm diameters.<br />

• 70mm, 95mm, 120mm and 145mm<br />

lengths.<br />

• 1 x special drill-to-bit connector.<br />

• 1 x modular extension bar, 220mm length.<br />

• 3 x modular carbide tipped drill bits, 40mm<br />

length.<br />

• Choice of 16mm, 18mm and 20mm<br />

modular diameters.<br />

• Optional extra extension bar offers 20mm<br />

diameter holes at 450mm depth.<br />

• Components available individually on a<br />

replacement basis.<br />

installation and creating a cleaner, more accurate<br />

drill hole. For example, that can drastically reduce<br />

time accrued removing dust from the drill hole<br />

when installing mechanical anchors, virtually<br />

eliminating the need to blow the hole clean of<br />

dust.<br />

EJOT vortex V Industrial Vacuum<br />

The EJOT Vortex-SDS drilling system can be<br />

attached to any H-class industrial vacuum<br />

cleaner. As part of the system offering, EJOT<br />

partnered with international manufacturer Addex<br />

to provide a customised version of the MV-DV20<br />

VAC. The vacuum can be used on a variety of<br />

surfaces and can withstand the toughest of<br />

treatment.<br />

Contact EJOT<br />

01977 687040<br />

www.ejot.co.uk<br />

@EJOTUK_Building<br />

86 TC SEPTEMBER <strong>2019</strong>