3D Jail Project - IO1 - Competence framework for 3D printing in jail

Intellectual Output 1 The main innovative element of IO1 is to entail professionalizing competencies on the use of 3D printing technologies in the learning context of people with fewer opportunities because of their status of prisoners, ex-prisoners or subjected to alternative measures to detention. It is innovative because – in a pioneering way in Europe – it puts the basis to frame this kind of competencies in relation with restricted people, in the context of prison security, and it challenges penitentiary administrations to innovate their procedures and conditions to use even more ICT technologies inside their structures. It also poses prisons’ educational systems before the challenge to include these specific competencies in the educational experience of the inmates.

Intellectual Output 1 The main innovative element of IO1 is to entail professionalizing competencies on the use of 3D printing technologies in the learning context of people with fewer opportunities because of their status of prisoners, ex-prisoners or subjected to alternative measures to detention. It is innovative because – in a pioneering way in Europe – it puts the basis to frame this kind of competencies in relation with restricted people, in the context of prison security, and it challenges penitentiary administrations to innovate their procedures and conditions to use even more ICT technologies inside their structures. It also poses prisons’ educational systems before the challenge to include these specific competencies in the educational experience of the inmates.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

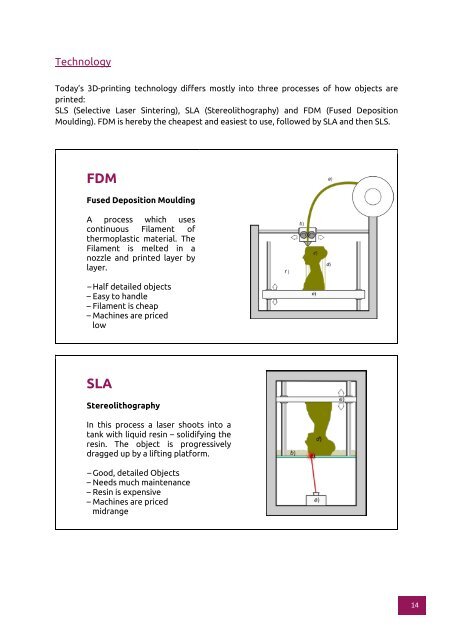

Technology<br />

Today’s <strong>3D</strong>-<strong>pr<strong>in</strong>t<strong>in</strong>g</strong> technology differs mostly <strong>in</strong>to three processes of how objects are<br />

pr<strong>in</strong>ted:<br />

SLS (Selective Laser S<strong>in</strong>ter<strong>in</strong>g), SLA (Stereolithography) and FDM (Fused Deposition<br />

Mould<strong>in</strong>g). FDM is hereby the cheapest and easiest to use, followed by SLA and then SLS.<br />

FDM<br />

Fused Deposition Mould<strong>in</strong>g<br />

A process which uses<br />

cont<strong>in</strong>uous Filament of<br />

thermoplastic material. The<br />

Filament is melted <strong>in</strong> a<br />

nozzle and pr<strong>in</strong>ted layer by<br />

layer.<br />

– Half detailed objects<br />

– Easy to handle<br />

– Filament is cheap<br />

– Mach<strong>in</strong>es are priced<br />

low<br />

SLA<br />

Stereolithography<br />

In this process a laser shoots <strong>in</strong>to a<br />

tank with liquid res<strong>in</strong> – solidify<strong>in</strong>g the<br />

res<strong>in</strong>. The object is progressively<br />

dragged up by a lift<strong>in</strong>g plat<strong>for</strong>m.<br />

– Good, detailed Objects<br />

– Needs much ma<strong>in</strong>tenance<br />

– Res<strong>in</strong> is expensive<br />

– Mach<strong>in</strong>es are priced<br />

midrange<br />

14