Sense of Change: Success Story Staufen AG

Many companies only think about reinventing themselves in times of need. But not FEIG ELECTRONIC GmbH. The market and innovation leader for controller and sensor technology as well as identification and payment systems exercises its versatility from a position of strength – and has been for many years.

Many companies only think about reinventing themselves in times of need. But not FEIG ELECTRONIC GmbH. The market and innovation leader for controller and sensor technology as well as identification and payment systems exercises its versatility from a position of strength – and has been for many years.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A decisive step in this lighthouse project was integrating module<br />

inspection and various pre and final assembly steps to form a<br />

clocked, high-performance production island in a one-piece flow.<br />

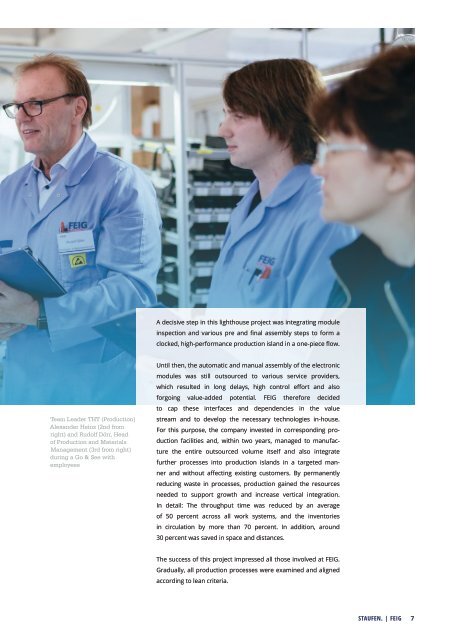

Team Leader THT (Production)<br />

Alexander Heinz (2nd from<br />

right) and Rudolf Dörr, Head<br />

<strong>of</strong> Production and Materials<br />

Management (3rd from right)<br />

during a Go & See with<br />

employees<br />

Until then, the automatic and manual assembly <strong>of</strong> the electronic<br />

modules was still outsourced to various service providers,<br />

which resulted in long delays, high control effort and also<br />

forgoing value-added potential. FEIG therefore decided<br />

to cap these interfaces and dependencies in the value<br />

stream and to develop the necessary technologies in-house.<br />

For this purpose, the company invested in corresponding production<br />

facilities and, within two years, managed to manufacture<br />

the entire outsourced volume itself and also integrate<br />

further processes into production islands in a targeted manner<br />

and without affecting existing customers. By permanently<br />

reducing waste in processes, production gained the resources<br />

needed to support growth and increase vertical integration.<br />

In detail: The throughput time was reduced by an average<br />

<strong>of</strong> 50 percent across all work systems, and the inventories<br />

in circulation by more than 70 percent. In addition, around<br />

30 percent was saved in space and distances.<br />

The success <strong>of</strong> this project impressed all those involved at FEIG.<br />

Gradually, all production processes were examined and aligned<br />

according to lean criteria.<br />

STAUFEN. | FEIG 7