Tradewinds August 2020 Web Final

August 2020 Edition of the Albemarle tradewinds

August 2020 Edition of the Albemarle tradewinds

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HRNeptune.com<br />

<br />

<br />

<br />

<br />

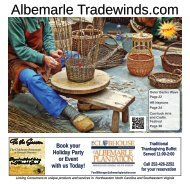

New yarn from old sweaters<br />

By Margaret Mills<br />

Reprinted with permissions from Backwoods Home Magazine Issue #132 • November/December, 2011<br />

Years ago, when my grandmother learned that some<br />

women purchased new fabric to make quilts, she was<br />

shocked. She was an “old-school” fiber artist — quilting,<br />

crocheting, and sewing to stretch her budget and provide<br />

for her family. Quilts were thriftily made of leftover bits of<br />

fabric; rugs were woven or braided from worn-out clothing.<br />

While the resurgence of these crafts brings some<br />

long-overdue respect for the artistry and skill of spinners,<br />

weavers, knitters, and seamstresses, the economics of<br />

such handwork has shifted. It is difficult these days to<br />

make a garment as cheaply as you can buy a similar<br />

item from a big box store. Thrift, of course, is not the only<br />

factor in the renewed interest in hand-crafting fiber items.<br />

For many, it may not be a factor at all.<br />

The variety of yarns now available in yarn and fabric<br />

shops boggles the mind — as does the price. Not content<br />

to stick with the economical and practical (but uninspired)<br />

acrylic yarn, I cast around for a means of acquiring wool<br />

yarn for less. One option in keeping with grandmother’s<br />

thrifty mindset is to salvage wool from a knitted or crocheted<br />

garment. Such recycling has also experienced<br />

a resurgence, so you can find a number of tutorials and<br />

articles on the internet detailing the process. A local fiber<br />

arts store even offers workshops on recycling yarn from<br />

sweaters.<br />

Recycling a free sweater is best, of course, and recycling<br />

the yarn from a sweater you already own would be ideal.<br />

Not having an old, out-of-style wool sweater lurking in<br />

the back of the closet, I began a search in our local thrift<br />

shop. While you might pick up a wool sweater at a yard<br />

sale for pennies, our thrift shop was sweater savvy: the<br />

pure wool sweaters were priced higher than the machine-made<br />

acrylic. Still, a wool sweater for under $10<br />

works for this project, and I found a selection.<br />

Look for a sweater that is close to 100% wool. A little<br />

nylon or acrylic serves to strengthen wool fibers and<br />

prevents breakage when you are unraveling the garment.<br />

Beware of felting, where the sweater has been washed<br />

in hot water or dried in a dryer. If you cannot differentiate<br />

the stitches, it is felted. Also beware of serged seams<br />

where the sewn edges of the sweater have been cut.<br />

The pieces of the sweater should be sewn or crocheted<br />

together. Also check for any moth damage to avoid<br />

winding up with little short bits of yarn when you unravel<br />

the sweater. Likewise, any fancy knit-in color patterns will<br />

result in lots of short bits of yarn.<br />

I finally located a $7 sweater with seams sewn with the<br />

same yarn. This sweater was a drab green mixture of<br />

mohair and wool with 5% nylon. It was hand-knit in Italy,<br />

but it was not particularly fashionable or attractive.<br />

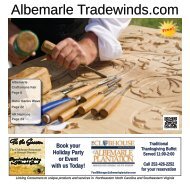

Dismantle<br />

The first step is to dismantle the sections of the sweater.<br />

A pair of sewing scissors or sharp-pointed embroidery<br />

scissors is good for this. A tapestry needle is useful for<br />

picking out those stitches, too. Locate the seams, then<br />

clip the knot or backstitch holding the seam together at<br />

the end. Remove the thread.<br />

With this sweater, the mohair tended to tangle around<br />

itself, and the thread holding the seam was the same<br />

green yarn, so it was difficult to see. Still, the sweater<br />

was reasonably easy to dismantle. I took the sleeves<br />

off first, then removed the front sections from the back<br />

section. There were also buttons to remove.<br />

Unravel<br />

Once the sweater is dismantled, begin the unraveling<br />

process by finding the end of the work. The knitter will<br />

probably have knotted the end after the final stitch, or<br />

woven it into the body. Many, but not all, sweaters are<br />

knit from the top down, so tug at the bottom corners first.<br />

Loosen the first thread and pull. It should unravel. If you<br />

find yourself undoing each stitch, you are pulling from<br />

the wrong end. Wrap the yarn in a ball as you unravel to<br />

prevent it from tangling. Unraveling our Italian hand-knit<br />

sweater was pretty straightforward. The mohair tended to<br />

tangle and resist pulling, but that only slowed the process<br />

slightly. I had several balls of yarn when finished, at least<br />

one for each sweater section.<br />

Skein<br />

The yarn will be kinky from the knitting. The next step is<br />

to wrap it in hanks. If you wish to measure the amount<br />

of yarn you have salvaged, set two chairs back to back,<br />

then measure a two-yard piece of string and wrap it<br />

around the chair backs, adjusting the chairs to measure<br />

exactly two yards. Wrap the salvaged yarn around the<br />

chair backs. This creates hanks exactly one yard long.<br />

You will be able to determine the amount of yarn you<br />

have by counting the strands in each hank. Use this<br />

opportunity to combine some of your balls of yarn as<br />

well. Just tie the ends together and keep wrapping. Don’t<br />

make them too thick or they will take too long to dry<br />

when washed. I ended up with four hanks of yarn. Tie the<br />

hanks in two places with a piece of string or light yarn to<br />

hold them in place.<br />

Wash<br />

Fill a pan or sink with lukewarm water. Do not use hot<br />

water as you do not want to felt the wool. Add a gentle<br />

detergent to the water and submerge the hanks for about<br />

three hours. Rinse the hanks of yarn in cool water and<br />

gently press out the excess water. Hang them to dry on a<br />

clothes rack or over the shower curtain. I left them to dry<br />

overnight, but much depends on your humidity, temperature,<br />

and the amount and weight of the wool. Some people<br />

recommended weighting the hanks to further straighten<br />

the yarn, but mine straightened quite well without any<br />

additional weight.<br />

Once the wool is dry and straightened to your satisfaction,<br />

take it down from the rack and roll it into balls. I<br />

ended my experiment with more than 400 yards of green<br />

mohair yarn, for several hours’ work and a $7 investment.<br />

https://www.backwoodshome.com<br />

24 Albemarle <strong>Tradewinds</strong> <strong>August</strong> <strong>2020</strong> albemarletradewinds.com