OVERDRIVE® - RustoleumIBG.Com

OVERDRIVE® - RustoleumIBG.Com

OVERDRIVE® - RustoleumIBG.Com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

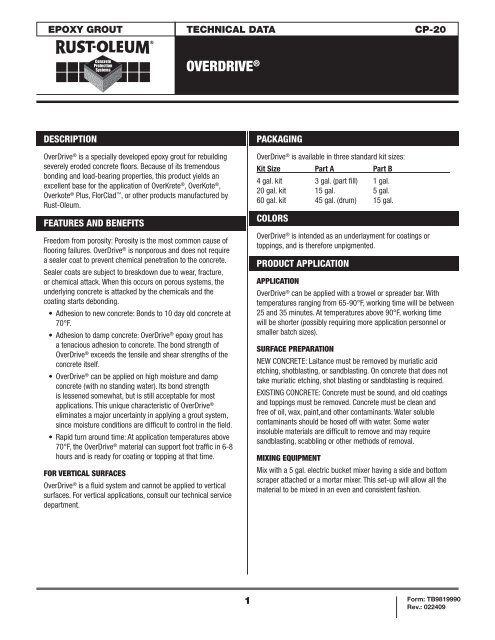

EPOXY GROUT<br />

DESCRIPTION<br />

TECHNICAL DATA CP-20<br />

OVERDRIVE ®<br />

OverDrive ® is a specially developed epoxy grout for rebuilding<br />

severely eroded concrete floors. Because of its tremendous<br />

bonding and load-bearing properties, this product yields an<br />

excellent base for the application of OverKrete ® , OverKote ® ,<br />

Overkote ® Plus, FlorClad , or other products manufactured by<br />

Rust-Oleum.<br />

FEATURES AND BENEFITS<br />

Freedom from porosity: Porosity is the most common cause of<br />

flooring failures. OverDrive ® is nonporous and does not require<br />

a sealer coat to prevent chemical penetration to the concrete.<br />

Sealer coats are subject to breakdown due to wear, fracture,<br />

or chemical attack. When this occurs on porous systems, the<br />

underlying concrete is attacked by the chemicals and the<br />

coating starts debonding.<br />

• Adhesion to new concrete: Bonds to 10 day old concrete at<br />

70°F.<br />

• Adhesion to damp concrete: OverDrive ® epoxy grout has<br />

a tenacious adhesion to concrete. The bond strength of<br />

OverDrive ® exceeds the tensile and shear strengths of the<br />

concrete itself.<br />

• OverDrive ® can be applied on high moisture and damp<br />

concrete (with no standing water). Its bond strength<br />

is lessened somewhat, but is still acceptable for most<br />

applications. This unique characteristic of OverDrive ®<br />

eliminates a major uncertainty in applying a grout system,<br />

since moisture conditions are difficult to control in the field.<br />

• Rapid turn around time: At application temperatures above<br />

70°F, the OverDrive ® material can support foot traffic in 6-8<br />

hours and is ready for coating or topping at that time.<br />

FOR VERTICAL SURFACES<br />

OverDrive ® is a fluid system and cannot be applied to vertical<br />

surfaces. For vertical applications, consult our technical service<br />

department.<br />

1<br />

PACKAGING<br />

OverDrive ® is available in three standard kit sizes:<br />

Kit Size Part A Part B<br />

4 gal. kit 3 gal. (part fill) 1 gal.<br />

20 gal. kit 15 gal. 5 gal.<br />

60 gal. kit 45 gal. (drum) 15 gal.<br />

COLORS<br />

OverDrive ® is intended as an underlayment for coatings or<br />

toppings, and is therefore unpigmented.<br />

PRODUCT APPLICATION<br />

APPLICATION<br />

OverDrive ® can be applied with a trowel or spreader bar. With<br />

temperatures ranging from 65-90°F, working time will be between<br />

25 and 35 minutes. At temperatures above 90°F, working time<br />

will be shorter (possibly requiring more application personnel or<br />

smaller batch sizes).<br />

SURFACE PREPARATION<br />

NEW CONCRETE: Laitance must be removed by muriatic acid<br />

etching, shotblasting, or sandblasting. On concrete that does not<br />

take muriatic etching, shot blasting or sandblasting is required.<br />

EXISTING CONCRETE: Concrete must be sound, and old coatings<br />

and toppings must be removed. Concrete must be clean and<br />

free of oil, wax, paint,and other contaminants. Water soluble<br />

contaminants should be hosed off with water. Some water<br />

insoluble materials are difficult to remove and may require<br />

sandblasting, scabbling or other methods of removal.<br />

MIXING EQUIPMENT<br />

Mix with a 5 gal. electric bucket mixer having a side and bottom<br />

scraper attached or a mortar mixer. This set-up will allow all the<br />

material to be mixed in an even and consistent fashion.<br />

Form: TB9819990<br />

Rev.: 022409

PRODUCT APPLICATION<br />

TECHNICAL DATA<br />

OVERDRIVE ®<br />

MIXING<br />

The minimum temperature for application should be 65°F.<br />

For low temperature applications, consult Rust-Oleum. Use<br />

only motorized mixers. Hand mixing will produce inconsistent<br />

results. For each 1 gal. of OverDrive ® (part A and part B mixed),<br />

add 60 lbs. of aggregate (30 lbs. of 1/8-1/4 inch pea gravel<br />

plus 30 lbs. of clean graded 30-40 mesh sand). This mix will<br />

fill approximately 1/2 cubic foot area. The aggregate may be<br />

purchased locally or from Rust-Oleum.<br />

Pour part A (resin) and part B (hardener) into mixer. Mix for<br />

about 30 seconds. Immediately add pea gravel and sand. Mix<br />

only long enough to thoroughly disperse the aggregate (1.5 to<br />

3.0 minutes). Immediately pour onto the concrete.<br />

Because sand and gravel size will vary from region to region,<br />

the recommended 30 lbs. of 1/8-1/4 inch pea gravel and 30<br />

lbs. of sand is only a good starting point. If the mix is too wet,<br />

more sand and gravel can be added or 480 silica sand can be<br />

used. If the mix appears too dry, decrease the amount of sand<br />

or gravel accordingly.<br />

Note: Mixing ratios are supplied in kits and on container labels.<br />

For additional adhesion of toppings to OverDrive ® , a silica<br />

broadcast of 50 lbs. per 10 sq. ft. will provide an additional<br />

tooth for binding a heavy duty system.<br />

CLEAN UP<br />

Xylene can be used to remove material from equipment if it is<br />

cleaned before the material has started to set up; otherwise,<br />

stronger solvents such as methylene chloride will be necessary.<br />

If there are any questions on the use of this product, please<br />

consult our technical service department.<br />

SAFETY<br />

OVERDRIVE contains amine curing agents. Avoid skin contact.<br />

In case of eye contact or ingestion, contact a physician<br />

immediately. In case of skin sensitivity to these materials, use<br />

protective clothing and gloves.<br />

MATERIAL SAFETY DATA SHEETS<br />

Material Safety Data Sheets are available upon request. It<br />

is strongly recommended that they be read by all persons<br />

handling OverDrive ® .<br />

2<br />

Form: TB9819990<br />

Rev.: 022409

TECHNICAL DATA<br />

OVERDRIVE ®<br />

PERFORMANCE CHARACTERISTICS<br />

COMPRESSIVE STRENGTH<br />

METHOD: ASTM C579<br />

TYPICAL VALUE: 14,000 psi<br />

FLEXURAL STRENGTH<br />

METHOD: ASTM C580<br />

TYPICAL VALUE: 4,700 psi<br />

TENSILE STRENGTH<br />

METHOD: ASTM C307<br />

TYPICAL VALUE: 2,400 psi<br />

BOND STRENGTH TO CONCRETE<br />

METHOD: ASTM D4541<br />

TYPICAL VALUE: Exceeds tensile strength of concrete (concrete<br />

fails first)<br />

TABER ABRASION<br />

METHOD: ASTM 4060, CS 17<br />

TYPICAL VALUE: Loss/1000 cycles = 30 mg.<br />

WATER ABSORPTION<br />

METHOD: ASTM C413<br />

TYPICAL VALUE: 0.1% maximum<br />

LINEAR SHRINKAGE<br />

METHOD: ASTM C531<br />

TYPICAL VALUE: 0.12% maximum<br />

FLAMMABILITY<br />

METHOD: ASTM D635<br />

TYPICAL VALUE: Self-extinguishing<br />

IMPACT RESISTANCE<br />

METHOD: Mil-D-3134J<br />

TYPICAL VALUE: Satisfactory per 3.16<br />

COEFFICIENT OF FRICTION<br />

METHOD: ASTM D2047<br />

TYPICAL VALUE: 0.6 minimum<br />

FILM HARDNESS, SHORE D<br />

METHOD: ASTM D2240<br />

TYPICAL VALUE: 85<br />

3<br />

PERFORMANCE CHARACTERISTICS (cont.)<br />

POROSITY WITH NO SEALER<br />

METHOD: NACE Stand TM-01-74<br />

TYPICAL VALUE: 0.00<br />

USDA APPROVAL<br />

Yes<br />

Form: TB9819990<br />

Rev.: 022409

The technical data and suggestions for use contained herein are correct to the best of our knowledge, and offered in good faith. The statements of this literature do not constitute<br />

a warranty, express, or implied, as to the performance of these products. As conditions and use of our materials are beyond our control, we can guarantee these products only to<br />

conform to our standards of quality, and our liability, if any, will be limited to replacement of defective materials. All technical information is subject to change without notice.<br />

Rust-Oleum Corporation<br />

11 Hawthorn Parkway<br />

Vernon Hills, Illinois 60061<br />

An RPM <strong>Com</strong>pany<br />

Phone: 877•385•8155<br />

www.rustoleum.com/industrial<br />

Form: TB9819990<br />

Rev.: 022409